Connection instructions, Lp gas cylinder information, Leak test – King Kooker Jet and Combination Burners User Manual

Page 14: Figure 1

14

connectIon InstructIons

1. Check that your hose assembly valve is set to not allow gas flow. If you have an adjustable

regulator, turn the regulator control counterclockwise until it stops. This is the OFF position. If

you have a non-adjustable regulator with a manual valve(s), turn the manual valve(s) clockwise

until it stops. This is the OFF position.

2. Attach the regulator to the cylinder valve by turning the Type 1 fitting clockwise. Hand tighten with

the regulator positioned upright. Refer to the appropriate assembly diagram for the appliance,

page 12.

3. Perform the Leak Test:

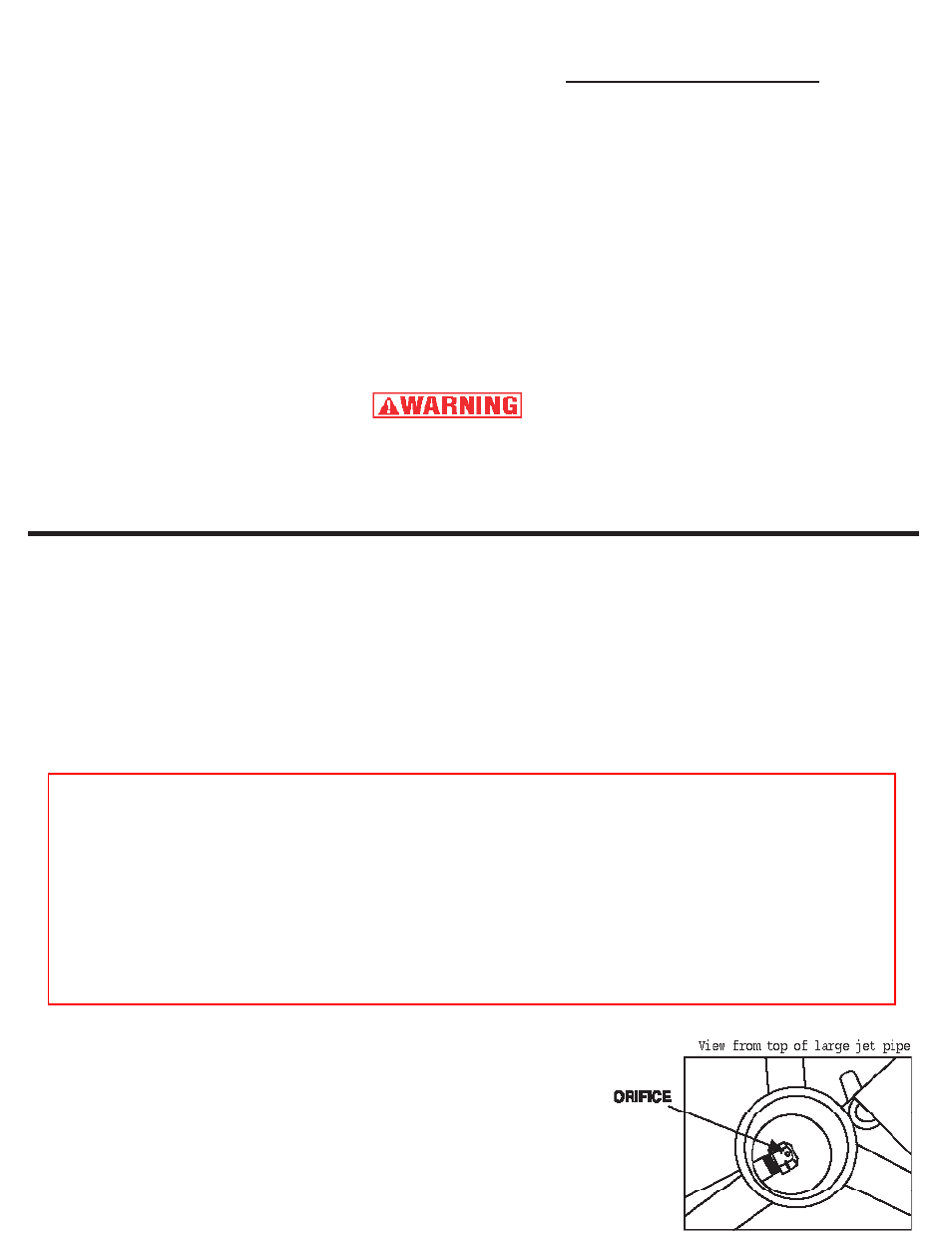

4. Before lighting the cooker, check that the jet pipes, orifice

and venturi tube on cast burners are free from obstruction.

The orifice under the jet tube should be positioned pointing

up directly through the tube as per Figure 1. The orifice on

cast burners must be properly threaded into the venturi tube

as per instructions on page 12. Both situations must be

corrected if necessary before lighting to prevent flashback.

lp gAs cylInder InFormAtIon

King Kooker® Outdoor Cookers are manufactured for use with 20lb. (9 kg) lp gas cylinders. Important

information to remember about LP Gas cylinders include:

1.

Always read and follow the cylinder manufacturer’s instructions.

2.

Make sure that the gas cylinder is not overfilled. The maximum weight of a properly filled 20 lb. (9 kg) LP

gas cylinder is approximately 38 lbs (17 kg). Never fill the cylinder beyond 80% full.

3.

Make sure that the cylinder valve has the proper connection for a Type 1 appliance fitting.

4.

Do not store a spare LP gas cylinder under or near this appliance.

5.

Disconnect the cylinder from the cooker for storage.

6.

Store the cylinder out of the reach of children.

7.

Do not use or store the cylinder in a building, garage or enclosed area.

8.

Always use a 20 lb. (9 kg) cylinder in the proper upright position for the proper vapor withdrawal. It should

also be stored and transported in the upright position.

9.

The cylinder must have a protective collar to protect the cylinder valve.

10. Place dust cap on cylinder valve outlet whenever the cylinder is not in use. Only install the type of dust

cap on the cylinder valve outlet that is provided with the cylinder valve. Other types of caps or plugs may

result in leakage of propane.

11. Cylinder must be turned OFF while not in use.

AlwAys reAd And Follow these And the cylInder mAnuFActurer’s InstructIons. FAIlure

to Follow these InstructIons And wArnIngs could result In FIre, explosIon,

burn hAzArd or cArbon monoxIde poIsonIng whIch could cAuse property

dAmAge, personAl Injury or deAth.

leAK test

Before lighting the appliance, a thorough leak test must be satisfactorily completed using

a non-ammonia soapy water solution (50% non-ammonia soap and 50% water). This is to be

applied with a small brush to all gas joints after the cylinder valve is opened (no more than

1/2 turn). If bubbles are seen, indicating a leak, turn off the cylinder and tighten the leaking

connection until a further leak test shows no leaks.

If tightening the connection does not stop the leak, call Metal Fusion, Inc. (800) 783-3885,

for assistance.

neVer use hose/regulAtor Assembly IF leAKIng.

FIgure 1