Keter Dallas 6 User Manual

Dallas fence, Assembly instructions, Important

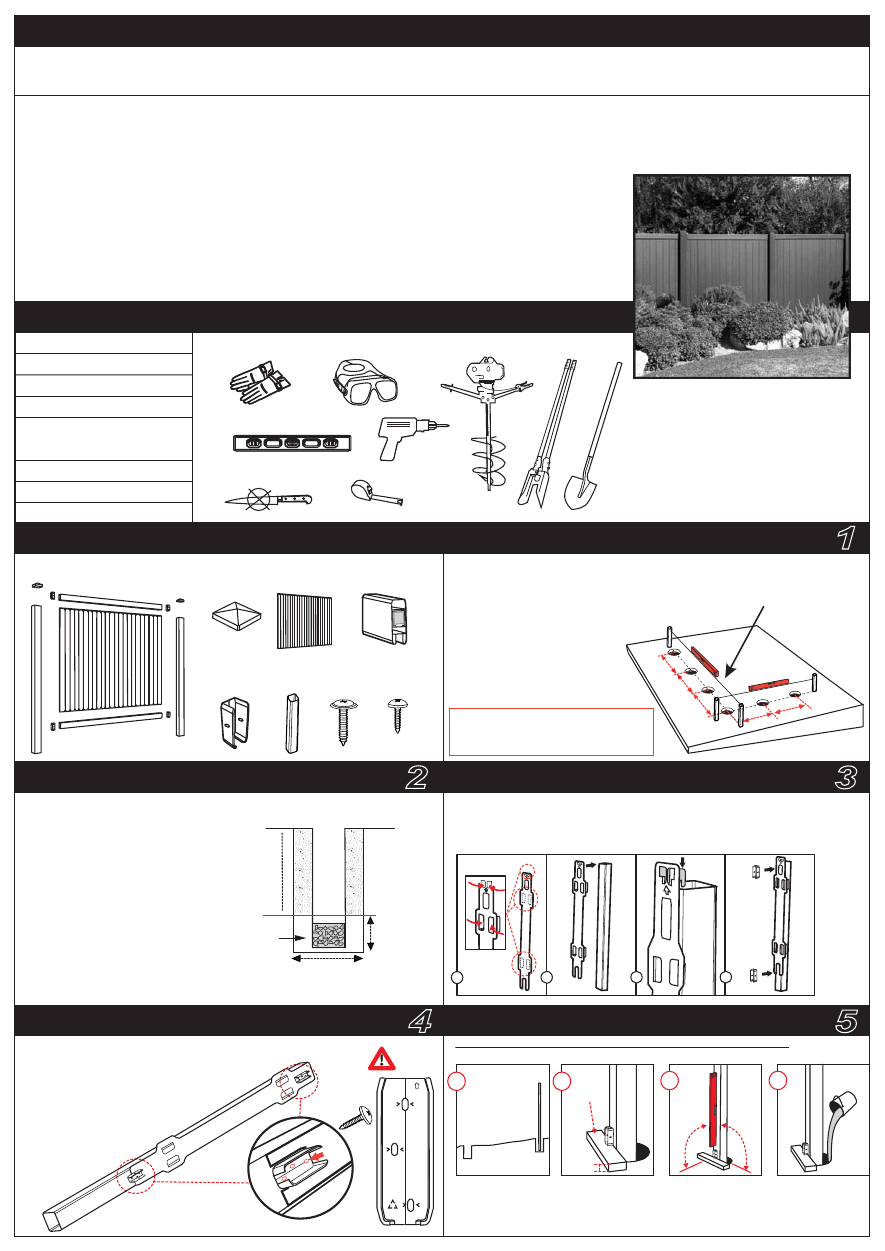

POST

x 2

PANEL

x1

RAILS

x 2

SC35B x8

(1.4”)

BRACKET

x4

fcb

u

POST

CAP x2

SC15 x12

(0.6”)

up

fcb

up

X3

Hole diameter (12”) 30cm

ASSEMBLY INSTRUCTIONS

DALLAS FENCE

ITEM : 000001 VER : 0 USA

IMPORTANT:

You must read these instructions carefully before you start to assemble this fence. Please carry out the steps in the order set out in these instructions.Keep these instructions

in a safe place for future reference.

GENERAL INFORMATION:

The Keter Fence is easy to install. We incorporate methods and procedures used by professional installers to guide you through to the successful

completion of your fence.

GENERAL ADVICE:

This is a 2 person assembly job.If it is a property line fence, you will want to confirm your property lines

before ordering your fence.The component parts should be checked and laid out in an orderly way, close at hand.Keep all small parts

(screws, etc.) in a bowl so that they do not get lost.

Please keep the tracking number which appears on the box, and refer to this number when calling the service office for questions or complaints.

CARE & MAINTENANCE :

When your fence needs a clean, use a mild detergent solution and rinse with cold clean water.

DO NOT use acetone, abrasive cleaners or other special detergents to clean the fence.

For general support and replacement parts, please contact :

U.S: Call Toll Free:1-(888)-374-4262 , fax 317-575-4502, 11495 North Pennsylvania ST., Suite 110 Carmel, Indiana, 46032, U.S.A

Canada: Tel: 514-7486-721 , Fax: 514-7487-793 , E-mail: [email protected]

United Kindom: Keter (UK) Ltd. Unit 4, Woodgate Business Park, Clapgate Lane, Birmingham, B32 3DB, United Kindom. Tel: 0121-5060008, Fax: 0121-4220808

The Netherlands: Keter Benelux, Ericssonstraat 17, Postbus 224, 5120 AE Rijen, The Netherlands. Tel: 31-1612-28301, Fax: 31-1612-28322

TOOLS & MATERIALS

string line

post hole digger / power auger

mallet

work shoes

4 timber stakes

2”x 2”x24” (5cm x 5cm x 60cm)

concrete / dry mix

PARTS & DIMENSION

String fence line to show

horizontal accuracy

PROJECT PLANNING

1. Stake out fence from beginning to end.

.2. Estimate the ground level.

3. Start at the

highest side

of the fence line !

4. Dig hole under post line. make sure the

distance between holes centers is 6’ (183cm).

6’

183cm

183cm

183cm

183cm

183cm

6’

6’

6’

6’

3

GENERAL ADVICE ON POST HOLES

POSITIONING GUIDE

5

BRACKETS ASSEMBLY

FIXING FIRST POST

4

1. Use the positioning guide to place the brackets .

A. fold the positioning guide wings.

B. Attach the positioning guide to the post as shown.

C. Place the bracket within the positioning guide holes.

Top of

bracket

POST

TOP

1

A. Position the first post at the highest ground point of the fence line

!

B. Place 2’’ (5cm) timber, under the bracket to maintain the gap between the fence and the ground.

C. Check for VERTICAL in two directions.

D. Fill the hole with concrete leaving a slope for water drainage.

E. Allow concrete to set for 10-15 minutes

Place first post in the hole, checking that it satisfies ALL the following conditions:

2

Gravel to reduce

frost HEAVE

(6”) 15cm

below frost line

Using post hole digger or power auger

or simple shovel dig the hole 12” (30cm)

in diameter. Main and gate posts should

be 6” (15cm) deeper for extra strength.

Backfill each hole with 6” of gravel to drain

water away.

(24”)

65cm

hole depth

1.

using the positioning guide.

2.Do not assemble brackets on both sides

of the post !

3.Locate all bracket screws on center

of elongated holes on bracket for

expansion and contraction.

The lip of the bracket

should be on the

bottom.

www.keter.co.il

B

A

C

D

builder's

level.

90

o

90

o

VERTICAL

C

D

ADD CONCRETE

2”

TIMBER

HEIGHT

B

GROUND

A

START AT THE HIGHEST

GROUND POINT

Attach two rail bracketsTS to One side of the posts

For fence sections that are less than the standard

6’ (183 cm) center-to-center, simply cut to size the

rails and the fence panels, using a power saw

(use metal fit blade).

.

A-13-00 544993