Mw/s series, General pump – General Pump MW Owners Manual User Manual

Page 5

Page 5

GENERAL PUMP

A member of the Interpump Group

MW/S SERIES

Note: appropriate clothing will effectively protect against water spray, but it may not offer adequate protection against the

direct impact of water jets or sprays from a close distance. Some circumstances may require further protection.

3. It is generally best to organize personnel into teams of at least two people capable of giving mutual and immediate

assistance in case of necessity and of taking turns during long and demanding operation.

4. Access to the work area that is within the water jets’ range must be absolutely prohibited to and free from objects

that, inadvertently under a pressure jet, can be damaged and or create dangerous situations.

5. The water jet must only and always be directed in the direction of the work area, including during testing or

preliminary tests or checks..

6. The Operator must always pay attention to the trajectory of the debris removed by the water jet. If necessary,

suitable guards must be provided by the Operator to protect anything that may be accidentally exposed.

7. The Operator should not be distracted for any reason during operation. Workers needing to access the operating

area must wait for the Operator to stop work, and then immediately make their presence known.

8. For safety reasons, it is important that each member of the team is fully aware of the intentions and actions of

other team members in order to avoid dangerous misunderstandings.

9. The high pressure system must not be started up and run under pressure without all team members in position

and without the Operator having already directed his/her lance toward the work area.

3.5 Safety During System Maintenance

1. The pressure system meintenance must be carried out in the time intervals set by the manufacturer who is

responsible for the whole group according to law.

2. Maintenance should always be carried out by trained and authorized personnel.

3. Assembly and disassembly of the pump and its various components must be performed exclusively by authorized

personnel, using appropriate equipment in order to avoid damage to components and connections.

4. Always use original spare parts to ensure total reliability and safety.

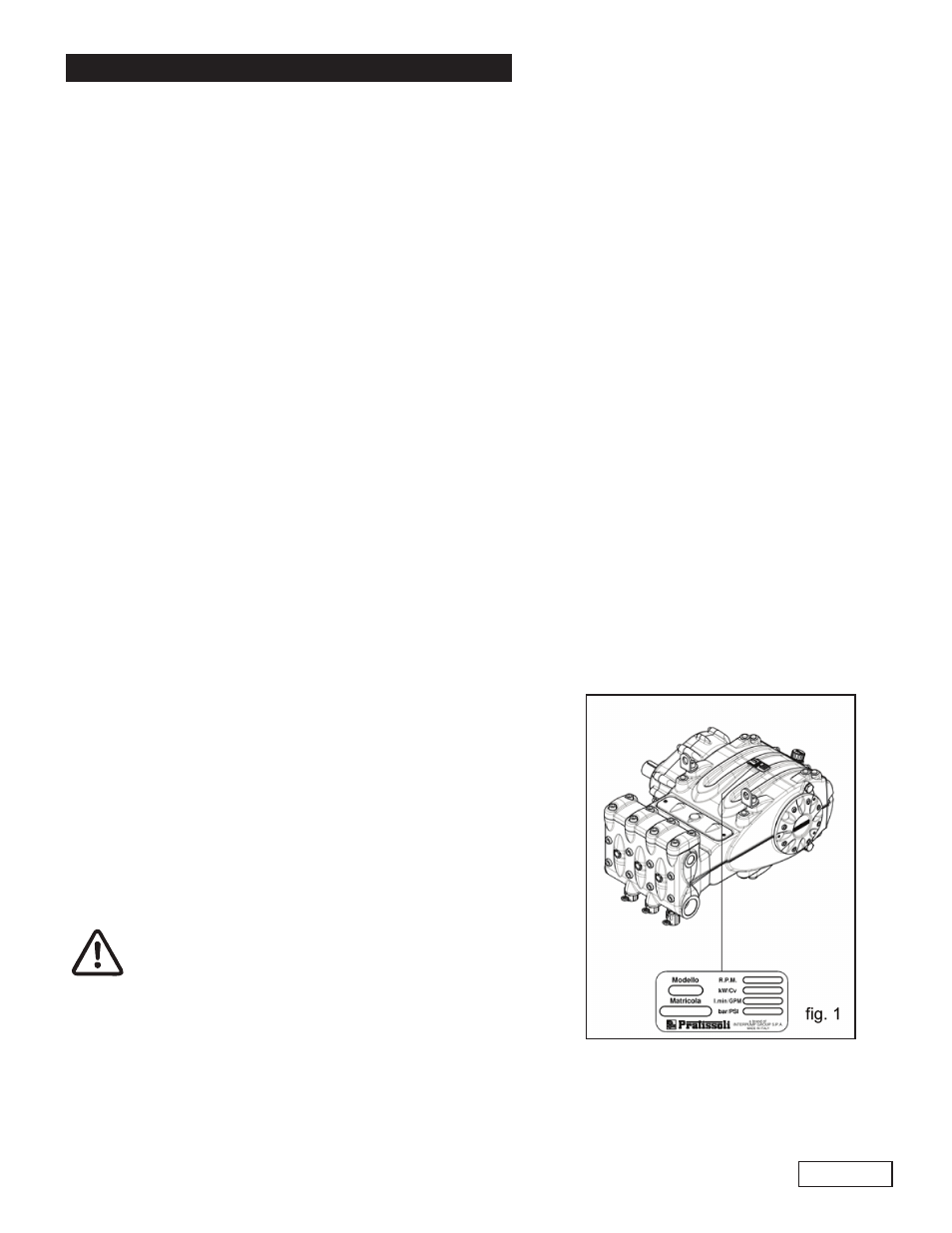

4. PUMP IDENTIFICATION

Each pump has a specific label which contains:

Pump model and version

Serial Number

Flow Rate - GPM

Pressure - PSI

Power - Hp-kW

Maximum RPM

Pump model, version and serial number must always

be specified when ordering spare parts.

Ref 300790 Rev.D

11-12