Typical code = b25. p t. b b. t t p - t 05 – Blagdon Pump X25 Non-Metallic User Manual

Page 4

HG-CF-1187 Rev. E - 03.03.14

Page 4

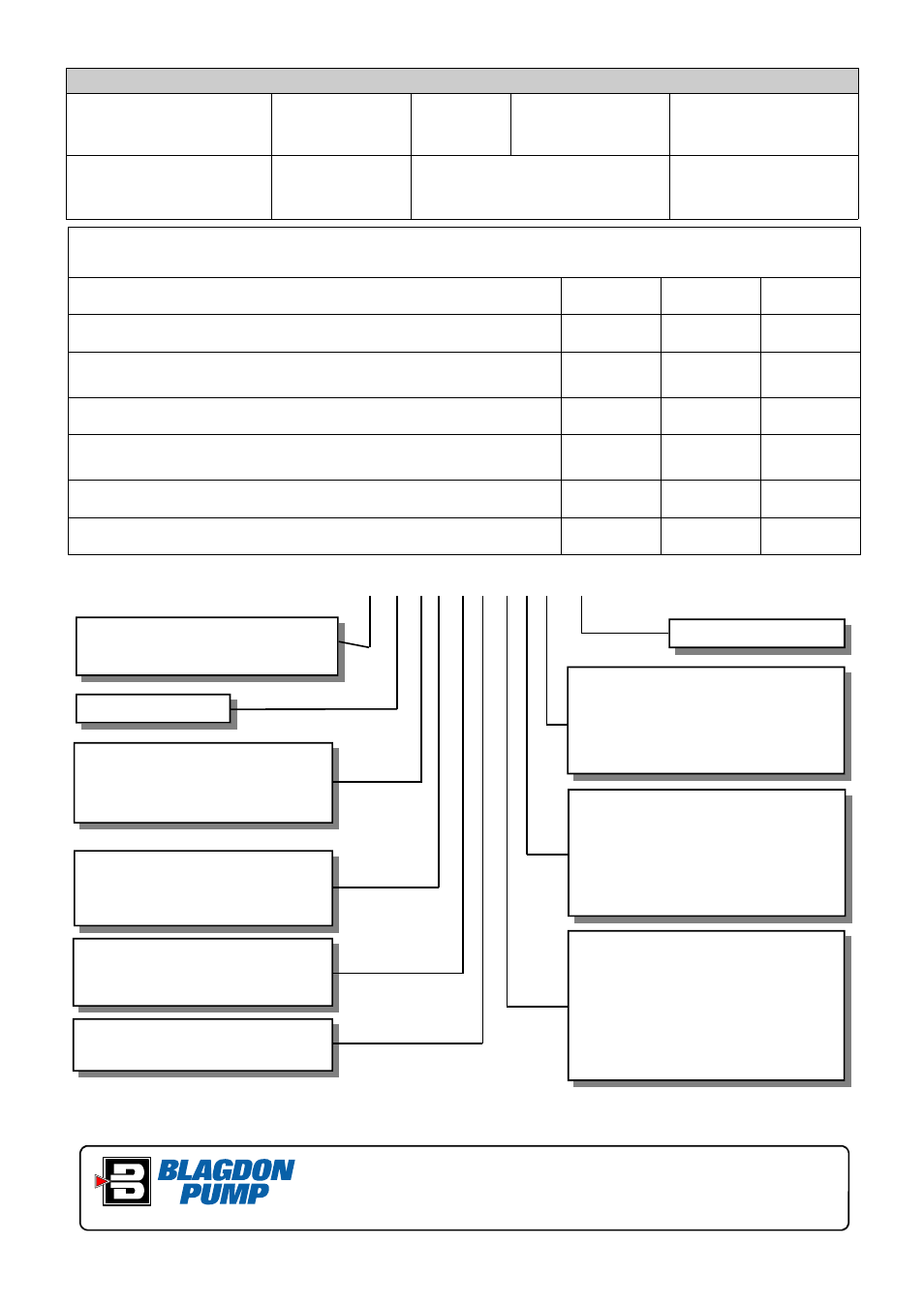

TYPICAL CODE =

B25.

P T. B B. T T P - T

05.

TECHNICAL DATA

FLUID CONNECTIONS

CAPACITY

MAX SOLIDS

MAX DISCHARGE HEAD

DISPLACEMENT/STROKE

1” ANSI 150 / DN25

Compatible Flange

0 - 152 Liters/Minute

(0 - 33 Gallons/Minute)

3 MM

(1/8”)

88 Meters

(289 ft)

0.475 Litres

(0.1 UK Gallons)

MAX. WORKING PRESSURE

AIR INLET

TEMPERATURE LIMITS

PUMP WEIGHTS :-

8.6 Bar (125 psi)

3/8” BSP (F)

Polypropylene :- 70

o

C

PVDF (Kynar) :- 90

o

C

PT/GT :- 13.3 Kg PW/GW :- 15 Kg

KT :- 20 Kg

KW :- 21.7 Kg

Caution -

Operating temperature limitations are as follows:

Operating Temperatures

Materials

Maximum

Minimum

Optimum

Buna-n -

General purpose, oil resistant. Shows good solvent, oil, water and hydraulic fluid resistance. Should not

be used with highly polar solvents like acetone and MEK, ozone, chlorinated hydrocarbons and nitro hydrocarbons.

176

o

F

80

o

C

-18

o

F

-28

o

C

50

o

to 140

o

F

10

o

to 60

o

C

EPDM -

Shows very good water and chemical resistance. Has poor resistance to oils and solvents, but is fair on

ketones and alcohols.

212

o

F

100

o

C

-11

o

F

-24

o

C

50

o

to 212

o

F

10

o

to 100

o

C

Neoprene -

All purpose. Resistant to vegetable oil. Generally not affected by moderate chemicals, fats greases

and many oils and solvents. Generally attacked by strong oxidising acids, ketones, esters, nitro hydro carbons and

chlorinated aromatic hydrocarbons.

212

o

F

100

o

C

-4

o

F

-20

o

C

50

o

to 130

o

F

10

o

to 54

o

C

Santoprene® -

Injection moulded thermoplastic elastomer with no fabric layer. Long mechanical flex life.

Excellent abrasion resistance.

212

o

F

100

o

C

-10

o

F

-23

o

C

50

o

to 212

o

F

10

o

to 100

o

C

Virgin PTFE -

Chemically inert, virtually impervious. Very few chemicals are known to react chemically with

PTFE : molten alkali metals, turbulent liquid or gaseous fluorine and a few fluoro-chemicals such as chlorine

trifluoride or oxygen difluoride which readily liberate free fluorine at elevated temperatures.

356

o

F

180

o

C

32

o

F

0

o

C

50

o

to 212

o

F

10

o

to 100

o

C

Viton® -

Shows good resistance to a wide range of oils and solvents : especially all alphatic, aromatic and

halogenated hydrocarbons, acids, animal and vegetable oils.

356

o

F

180

o

C

0

o

F

-18

o

C

75

o

to 212

o

F

24

o

to 100

o

C

Polypropylene -

High strength, light weight, corrosion resistant polyolefin which easily withstands most

chemicals, with no known solvent at room temperature.

158

o

F

70

o

C

32

o

F

0

o

C

50

o

to 140

o

F

10

o

to 60

o

C

MODEL

B25 : STANDARD

X25 : ATEX CAT. 2 (Conductive Poly. Only)

WETTED COMPONENTS

P : POLYPROPYLENE

G : CONDUCTIVE POLYPROPYLENE

K : KYNAR (PVDF)

NON - WETTED COMPONENTS

T : ALUMINIUM / EPOXY PAINTED

W : ST. STEEL / EPOXY PAINTED

VALVE TYPE

B : BALL

W : WEIGHTED BALL

SUCTION ORIENTATION

B : BOTTOM

VALVE SEATS

B : BUNA-N

N : NEOPRENE

E : EPDM

K : PVDF (KYNAR)

P : POLYPROPYLENE

VALVE BALLS

B : BUNA-N

T : PTFE

E : EPDM

V : VITON

D : DELRIN (ACETAL)

N : NEOPRENE

S : STAINLESS STEEL

DIAPHRAGMS

B : BUNA-N

T : PTFE

E : EPDM

V : VITON

H : POLYESTER (HYTREL)

N : NEOPRENE

R : SANTOPRENE

O : ONE-PIECE PTFE

TAPPED MANIFOLDS

DESIGN LEVEL

IMPORTANT

This pump should be used in accordance with the requirements of the Safety, Health & Welfare at Work Act 2005.

All business conducted subject to IDEX Pump Technologies, Ireland. Terms and Conditions of Sale, available on request.

IDEX Pump Technologies (Ireland) Ltd.,

A Unit of IDEX Corporation,

R79, Shannon, Co Clare, IRELAND.

TEL. : +353 61 471933 FAX. : +353 61 475046

Web Site : www.blagdonpump.com

E-Mail