Materials, Typical code= x25. 01. c. c. f. t. b. b. s, Ii 2gd t5 – Blagdon Pump X25 Metallic User Manual

Page 4

x25fvmdl1sm-rev0411

Page 2

Type

Manifold & Outer

Inner

Outer

Inner

Intermediate Diaphragm Valve Hard- Diaphragm Flap

Seat/

Air

Air

Shipping

Elbow

Chamber Chamber Diaphragm Diaphragm Housing

Rod

Seat

ware

Valve Manifold Valve

Valve

Wt. (lbs)

Plate

Plate

Material

Seal

Cap

DB1A.

356-T6AL 356-T6AL AL380DC AL380DC

PS

AL380DC

416SS

SS

PS

B

B

B

PE AL380DC

48

DI1A.

356-T6AL 356-T6AL AL380DC AL380DC

PS

AL380DC

416SS

SS

PS

I

I

I

PE AL380DC

48

DN1A.

356-T6AL 356-T6AL AL380DC AL380DC

PS

AL380DC

416SS

SS

PS

N

N

N

PE AL380DC

48

DV1A.

356-T6AL 356-T6AL AL380DC AL380DC

PS

AL380DC

416SS

SS

PS

V

V

V

PE AL380DC

48

DP1A.

356-T6AL 356-T6AL AL380DC AL380DC

PS

AL380DC

416SS

SS

PS

S

S

I

PE AL380DC

48

DR1A.

356-T6AL 356-T6AL AL380DC AL380DC

PS

AL380DC

416SS

SS

PS

H

H

N

PE AL380DC

48

DA1A.

356-T6AL 356-T6AL AL380DC AL380DC

PS

AL380DC

416SS

SS

PS

N

U

N

PE AL380DC

48

DB1I.

CI

CI

AL380DC AL380DC

PS

AL380DC

416SS

SS

PS

B

B

B

PE AL380DC

61

DI1I.

CI

CI

AL380DC AL380DC

PS

AL380DC

416SS

SS

PS

I

I

I

PE AL380DC

61

DN1I.

CI

CI

AL380DC AL380DC

PS

AL380DC

416SS

SS

PS

N

N

N

PE AL380DC

61

DV1I.

CI

CI

AL380DC AL380DC

PS

AL380DC

416SS

SS

PS

V

V

V

PE AL380DC

61

DP1I.

CI

CI

AL380DC AL380DC

PS

AL380DC

416SS

SS

PS

S

S

I

PE AL380DC

61

DR1I.

CI

CI

AL380DC AL380DC

PS

AL380DC

416SS

SS

PS

H

H

N

PE AL380DC

61

DA1I.

CI

CI

AL380DC AL380DC

PS

AL380DC

416SS

SS

PS

N

U

N

PE AL380DC

61

DB1S.

SS

SS

AL380DC AL380DC

PS

AL380DC

416SS

SS

PS

B

B

B

PE AL380DC

64

DI1S.

SS

SS

AL380DC AL380DC

PS

AL380DC

416SS

SS

PS

I

I

I

PE AL380DC

64

DN1S.

SS

SS

AL380DC AL380DC

PS

AL380DC

416SS

SS

PS

N

N

N

PE AL380DC

64

DV1S.

SS

SS

AL380DC AL380DC

PS

AL380DC

416SS

SS

PS

V

V

V

PE AL380DC

64

DP1S.

SS

SS

AL380DC AL380DC

PS

AL380DC

416SS

SS

PS

S

S

I

PE AL380DC

64

DR1S.

SS

SS

AL380DC AL380DC

PS

AL380DC

416SS

SS

PS

H

H

N

PE AL380DC

64

DA1S.

SS

SS

AL380DC AL380DC

PS

AL380DC

416SS

SS

PS

N

U

N

PE AL380DC

64

DB1II.

CI

CI

CI

CI

PS

CI

416SS

SS

PS

B

B

B

PE

PE

76

DI1II.

CI

CI

CI

CI

PS

CI

416SS

SS

PS

I

I

I

PE

PE

76

DN1II.

CI

CI

CI

CI

PS

CI

416SS

SS

PS

N

N

N

PE

PE

76

DV1II.

CI

CI

CI

CI

PS

CI

416SS

SS

PS

V

V

V

PE

PE

76

DP1II.

CI

CI

CI

CI

PS

CI

416SS

SS

PS

S

S

I

PE

PE

76

DR1II.

CI

CI

CI

CI

PS

CI

416SS

SS

PS

H

H

N

PE

PE

76

DA1II.

CI

CI

CI

CI

PS

CI

416SS

SS

PS

N

U

N

PE

PE

76

DB1SI.

SS

SS

CI

CI

PS

CI

416SS

SS

PS

B

B

B

PE

PE

79

DI1SI.

SS

SS

CI

CI

PS

CI

416SS

SS

PS

I

I

I

PE

PE

79

DN1SI.

SS

SS

CI

CI

PS

CI

416SS

SS

PS

N

N

N

PE

PE

79

DV1SI.

SS

SS

CI

CI

PS

CI

416SS

SS

PS

V

V

V

PE

PE

79

DP1SI.

SS

SS

CI

CI

PS

CI

416SS

SS

PS

S

S

I

PE

PE

79

DR1SI.

SS

SS

CI

CI

PS

CI

416SS

SS

PS

H

H

N

PE

PE

79

DA1SI.

SS

SS

CI

CI

PS

CI

416SS

SS

PS

N

U

N

PE

PE

79

Meaning of Abbreviations:

AL = Aluminum

B = Nitrile

CI = Cast Iron

DC = Die Cast

H = Hytrel

I = EPDM

N = Neoprene

PE = Conductive HDPE

PS = Plated Steel

S = Sanotprene

SS = Stainless Steel

U = Urethane

V = FKM

Materials

Operating Temperatures

For specific applications, always consult “Chemical Resistance Chart" Technical Bulletin

Nitrile/FDA White Nitrile General purpose, oil-resistant. Shows good solvent, oil,

water and hydraulic fluid resistance. Should not be used with highly polar solvents

like acetone and MEK, ozone, chlorinated hydrocarbons and nitro hydrocarbons.

EPDM Shows very good water and chemical resistance. Has poor resistance

to oil and solvents, but is fair in ketones and alcohols.

NEOPRENE All purpose. Resistant to vegetable oils. Generally not affected

by moderate chemicals, fats, greases and many oils and solvents. Generally

attacked by strong oxidizing acids, ketones, esters, nitro hydrocarbons and

chlorinated aromatic hydrocarbons.

HYTREL

®

Good on acids, bases, amines and glycols at room temperature.

FKM (Fluorocarbon) shows good resistance to a wide range of oils and solvents;

especially all aliphatic, aromatic and halogenated hydrocarbons, acids, animal

and vegetable oils. Hot water or hot aqueous solutions (over 70°F) will attack FKM.

Urethane

Shows good resistance to abrasives. Has poor resistance to most

solvents and oils.

Santoprene

®

Injection molded thermoplastic elastomer with no fabric layer.

Long mechanical flex life. Excellent abrasion resistance.

Maximum

190°F

88°C

280°F

138°C

200°F

93°C

220°F

104°C

350°F

177°C

150°F

66°C

275°F

135°C

Minimum

-10°F

-23°C

-40°F

-40°C

-10°F

-23°C

-20°F

-29°C

-40°F

-40°C

32°F

0°C

-40°F

-40°C

CF-8M Stainless Steel equal to or exceeding ASTM specification A743 for corrosion resistant iron chromium, iron

chromium nickel, and nickel based alloy castings for general applications. Commonly referred to as 316 Stainless Steel in the pump industry.

To order a pump or replacement parts, first enter the Model Number HDF1, or HDF25, followed by the Type Designation listed below in the far left column.

Maximum and Minimum Temperatures are the limits for which

these materials can be operated. Temperatures coupled with

pressure affect the longevity of diaphragm pump components.

Maximum life should not be expected at the extreme limits of

the temperature ranges.

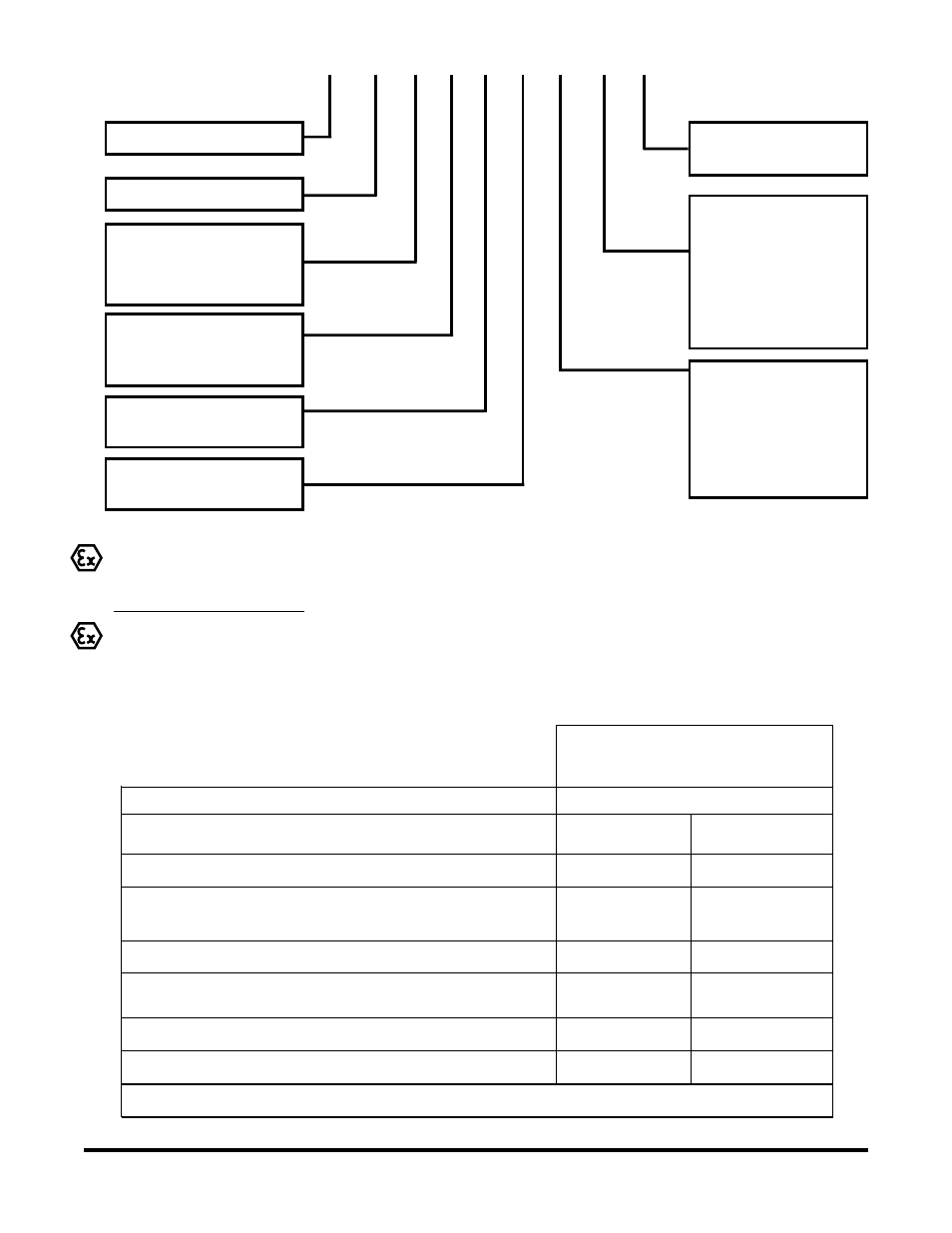

TYPICAL CODE=

X25. 01. C. C. F. T. B. B.

S.

Model - X25

Design Level

Non-Wetted Components

A: Aluminum

C: Cast Iron

Wetted Components

A: Aluminum

C: Cast Iron

S: Stainless Steel

Valve Type

F: Flap

Suction Orientation

T: Top

Valve Seats:

S: Stainless Steal

Flap Valves

B: Nitrile

N: Neoprene

R: Santoprene

P: Polyurethane

H: Hytrel

V: FKM

E: EPDM

Diaphragms

B: Nitrile

R: Santoprene

N: Neoprene

V: Viton

E: EPDM

H: Hytrel

Maximum delivery: 265 ltrs/min

Max. working pressure: 8.6 bar

Max. solid particle size: 25mm

Air inlet: 1/2” NPT

Temperatur limits: Determined by elastomers

Fluid inlet/outlet: 1" NPT or 1" BSP Tapered

Intallation: Surface mounted

Accessories included: Metal Exhaust air silencer

Shipping weights with

Aluminum mid sections: A: 52kg

B: 23kg

C: 24kg

Cast Iron mid sections: C: 29

S: 30

II 2GD T5

II 1G c T5

II 3/1 G c T5

II 1D c T100°C

I M1 c

I M2 c

Models equipped with Wetted

Options

C or S , Non-Wetted Options C.

Note: EC-Type Certificate.

II 2G c T5

II 3/2 G c T5

II 2D c T100°C

Models equipped with

Aluminium components

Note: Type Examination

II 2GD T5

II 2GD T5