General Technologies TA100 SmarTach + : Digital Tachometer and Engine Analyzer User Manual

Page 6

3- Observe the ignition peak voltage reading of the display. Some jumping of the readings

is normal and reflects actual changes in the peak voltages of the ignition system.

4- Record or memorize the maximum, minimum and average reading. Repeat the

test for each of the spark plug wires of the engine and note any readings that are

significantly higher or lower than the average.

5- Ignition problems may sometimes appear at higher engine RPM, but not at low

or idle speed. We recommend that measurements be made at idle speed and

normal engine operating temperature, and then at increasing RPM, and up to

equivalent of highway speeds, typically about 2000 to 2500 RPM. Do not exceed maximum

permissible (“red-line”) engine speeds. Make all measurements at about the same

engine speeds, using the TA100 tachometer function to check the RPM..

4.3.1 Diagnostic using the spark plug wire peak voltage

Small variations of up to 25% in the spark plug wire peak voltage from cylinder to cylinder

are normal, and do not necessarily indicate any problem. The placement of the pickup along

the spark plug wire will also cause some difference in the readings, due to the internal

resistance (or impedance) of the spark plug wire. For example, if the pickup is placed on

the spark wire near the distributor or DIS coil, voltage readings will be higher than if the

pickup is placed near the spark plug.

For diagnostic purposes, the attention should be focused on SIGNIFICANT DIFFERENCES

in readings caused by problems in the engine or the ignition system itself.

Common Causes of Low Voltage Readings

• Shorted, dirty or too small spark plug gap.

• Dirty or damaged spark plug insulator boot allowing spark “tracking” across insulator.

• Broken core in spark plug wire. Break is located between the distributor (or DIS coil) and

the test point.

• Short circuit, disconnection or partial disconnection between the distributor (or DIS coil)

and spark plug wire.

• Rich mixture. Most likely due to leaking fuel injector, or faulty oxygen sensor.

• Low cylinder compression pressure. Could be caused by leaking valve(s), worn piston

rings, blown cylinder head gasket, etc.

Common Causes of High Voltage Readings

• Spark plug gap too wide.

• Spark plug wire connector damaged, loose or disconnected.

• Broken core in spark plug wire. Break is located between the spark plug and the test

point.

• Lean mixture.

5. MAINTENANCE

2.1 Battery replacement

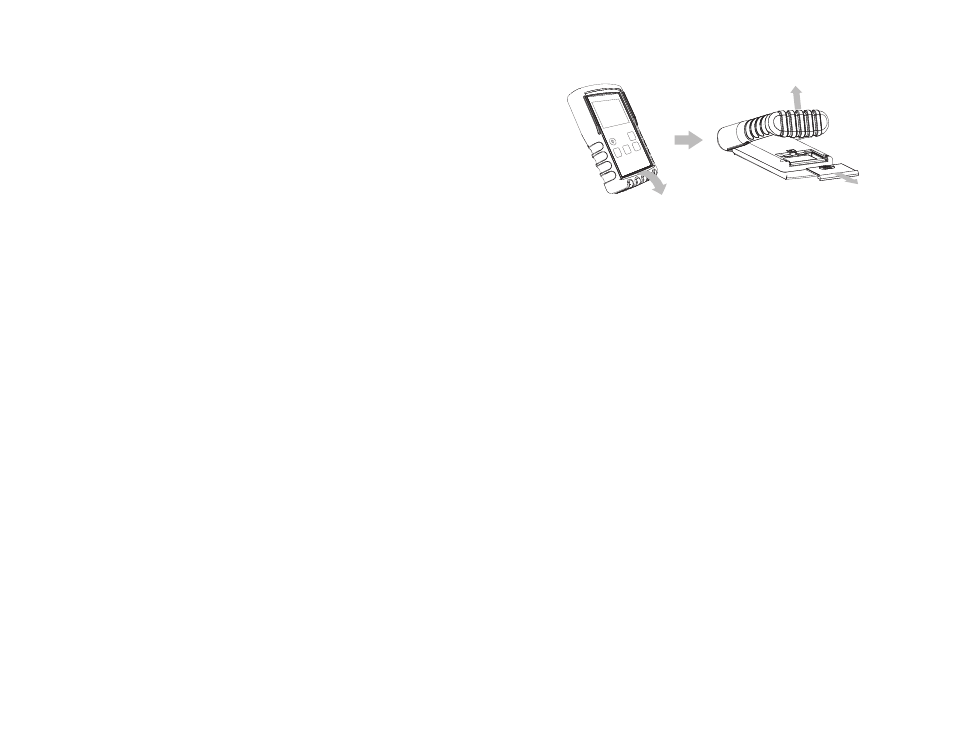

1- Release the rubber holster from plastic enclosure by pulling from the bottom of the

holster as shown in the illustration (Fig. 5)

2- Push the rubber holster forward until the battery compartment cover is exposed

3- Slide open battery cover located at the back of the unit.

4- Connect the new battery observing the polarity of the battery connectors.

5- Replace battery cover and rubber holster.

4- Press the Power On/Off / Reset button on the TA100 until the display turns on. If

the display does not turn on, check the battery polarity and reinstall if necessary.

To turn the unit off, press and hold the Power On/Off / Reset button again until the

display turns off.

5.2 Cleaning

Keep the instrument in its carrying case when not in use and do not subject it to dampness

or severe heat or cold. Do not use the instrument in the rain, if it should accidentally get

wet, dry it off with a clean paper towel before storing it away.

Protect the unit from contact with any solvents. Never clean with a solvent or petroleum

based medium such as gasoline, as these chemicals may attack the plastic parts and

cause permanent damage. Never use an abrasive cleaner. Cleaning should be limited to

wiping with a clean damp paper towel and a small amount of soap if required. Dry the unit

thoroughly after any cleaning.

The unit is a sealed instrument and contains no user serviceable parts other than the

battery, which can be replaced by opening the drawer on the back of the unit. Opening

other parts of the unit will void the warranty.

6. WARRANTY

With the exception of the battery, this instrument is warranted against defects of material

and workmanship which develop within a period of one (1) year following the date of pur-

chase by the original owner. For details see Standard Warranty Information on our web

page at www.gtc.ca or you may request a printed copy.

1

2

3

Fig 5 - Battery replacement

Page 9

Page 10