General Technologies ST05 Oxygen Sensor Tester and Simulator User Manual

Page 6

Page 10

Page 9

4. OxYGEN SENSOR INFORMATION

The oxygen sensor is one of the most critical parts of the emission control system and fuel

economy performance. This sensor measures the oxygen content in the exhaust gases,

and the result is used by the PCM (Powertrain Control Module) to adjust the amount of

fuel injected into the cylinders. Optimization of the fuel/air mixture minimizes the emission

of pollutants and reduces fuel consumption.

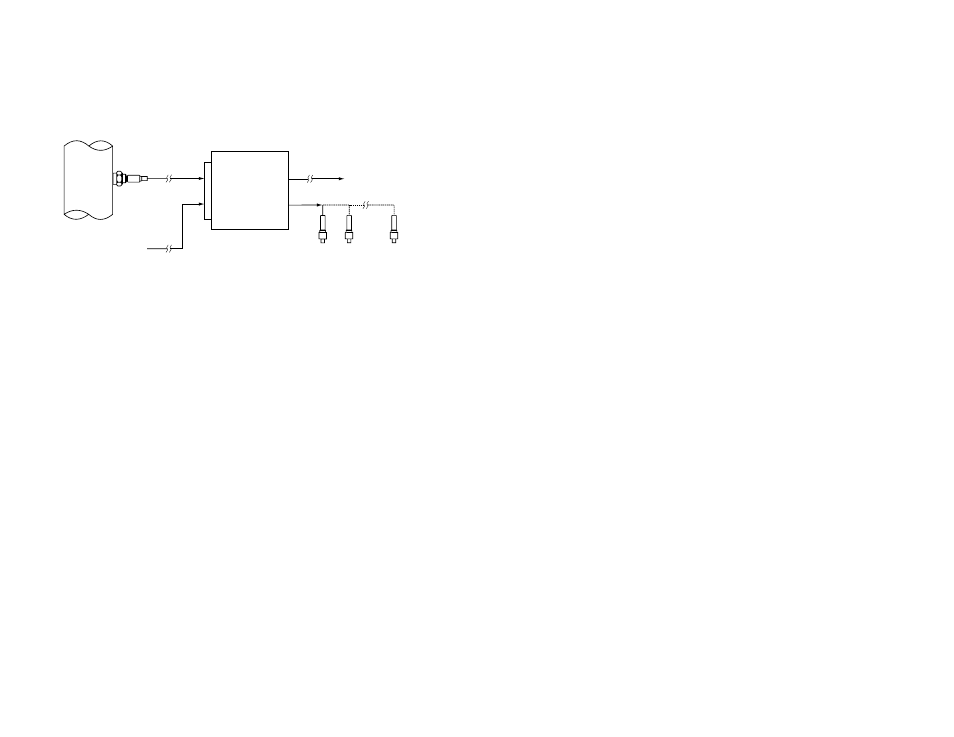

Fig. 4 - Oxygen sensor function

A high content (excess) of oxygen in the exhaust gases is indicative of a lean fuel mixture,

which causes higher combustion temperatures responsible for producing pollutants like

NOx, and may even cause permanent damage to the engine.

Low oxygen content in the exhaust indicates a rich fuel mixture, which generates Carbon

Monoxide and Hydrocarbon (unburned fuel) emissions, and reduces fuel economy.

Additional oxygen sensors located after the catalytic converters, are used to measure the

converter’s efficiency, insuring they are working properly in reducing emissions. The

optimal Air/Fuel mixture ratio is 14.7/1 (weight ratio), and it is called ‘Stoichiometric’.

4.1 Oxygen sensor types

4.1.1 Zirconia (Zirconium)

This is the most commonly used type of sensor, and it is based on the properties of Zir-

conium Dioxide (ZrO

2

), which becomes conductive at high temperatures, allowing oxygen

ions through it, creating an electrical charge on a platinum plate. These electrical charges

generate the signal output for the sensor.

The most important characteristics of this type of sensor are:

1- Zirconia sensors do not require any external power or signals, they generate their

own voltage.

2- Unheated (one wire) and heated (2, 3 and 4 wire) versions are used.

3- The sensor will become active (generate a signal) at around 600 °F

(315 °C), but to give an accurate output, the sensor temperature has to be at

approximately 800 °F (425 °C).

4- These sensors require an external oxygen reference level, which is achieved by allow-

ing some ambient air into the sensor. In some of the older versions, a small hole in the

back was used to let air into one side of the sensing element. The most modern ones

use the sensor wires as air conduits for the same purpose.

5- Output signal levels: when operating the output signal should switch to 0.8 Volt or above

on the high side (rich mixture) and to 0.2 V or below on the low side (lean mixture).

At the optimal mixture for maximum efficiency, or stoichiometric point (14.7 fuel to air

ratio), the sensor output is approximately 0.45 Volt, so anything above this voltage will

be interpreted by the PCM as a rich mixture, and anything below as a lean mixture.

6- Response time: is the time it takes the sensor to change its output from below 0.175

Volts to above 0.8 Volts, in response to a sudden change in the fuel mixture from lean

to rich. The response time should be less than 100 ms, a longer transition time or not

reaching the voltage levels indicated, is indicative of a defective sensor.

4.1.2 Titanium (Titania)

This type of sensors uses the properties of Titanium Dioxide (TiO

2

), which changes its

electrical resistance in relation to the oxygen content of the exhaust gases. Titanium sen-

sors do not require an external oxygen reference level, therefore are immune to external

factors, like air pollution, or contamination like water.

The most important characteristics of this type of sensor are:

1- Titanium sensors require external power, which is either 1 Volt or 5 Volt depending on

the vehicle and manufacturer specification.

2- These sensors are all of the heated type.

3- In order to work properly, the temperature of the sensor must be between 800 and

900° F ( 426 and 500° C).

4- Output signal levels: these depend on the external voltage supply being used, for 1

Volt systems, the signal should switch from close to 0 Volts for Lean to near 1 Volt for

rich mixtures, with the stoichiometric level at 0.5 Volt. For 5 Volt systems, the output is

generally reversed, near 0 Volts output for rich mixtures and 5 Volt for lean mixtures,

with 2.5 as the stoichiometric level.

6- Response time: It is the time it takes the sensor to change its output from below 0.2

Volts to above 0.8 Volts, in response to a sudden change in the fuel mixture from lean

to rich. The response time (as in the Zirconia sensors) should be less than 100 ms, and

a longer transition time or small voltage swings are indicative of a defective sensor.

4.1.3 Wide Band (Air/Fuel Ratio) single cell sensors:

These sensors look like conventional Zirconia heated sensors, however a specialized circuit

in the PCM controls the current to and from the sensor to obtain a signal proportional to

the fuel mixture.

For testing of the sensor in the vehicle, it is necessary to disconnect the signal wires of

the sensor from the PCM to prevent the circuitry from interfering with the sensor’s signal,

but the heater wires must remain connected. Once the signal wires are disconnected,

this sensor will behave the same as a conventional Zirconia sensor. An alternative way to

test this sensor is to do an off vehicle testing, (refer to section “4.2.3 Off vehicle testing of

oxygen sensors”).

This sensor has been in use in some Toyota vehicles since 1996.

Powertrain

Control

Module

Oxygen

sensor

Other sensors

(MAF, MAP, TPS, etc.)

Fuel Injectors

Other systems

(Ignition module, etc

)