Display description – General Technologies ST05 Oxygen Sensor Tester and Simulator User Manual

Page 3

Page 4

Page 3

3. OPERATION

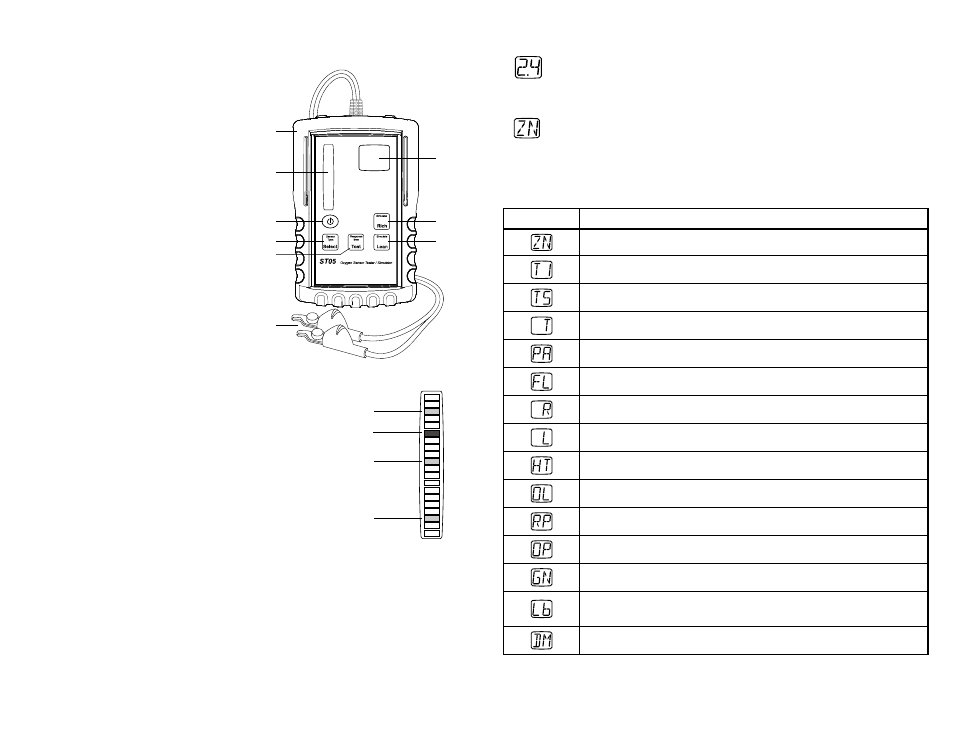

3.1 Instrument Description

1) Protective rubber holster

2) Alphanumeric display

3) Analog LED bargraph

4) Power ON/OFF button

5) Simulate sensor “RICH” condition

6) Sensor type select button

7) Simulate sensor “LEAN” condition

8) Response time test button

9) Test leads with clips

3.2.2 Alphanumeric display description

Numerical readout

During normal operation, the alphanumeric display shows the number of

crossings per second (cross-count) of the oxygen sensor signal.

Selection and message readout

When selecting the type of sensor, performing functions or during certain error

conditions, the alphanumeric display shows two characters codes that identify

the selection, status of a function, or error condition. Below is a table with display

readouts and their descriptions.

Display

Description

Zirconia sensor selected

Titanium sensor selected for 1 Volt systems

Titanium sensor selected for 5 Volt systems

Flashes while performing response time test

Passed the response time test ( < 100 ms)

Failed the response time test ( > 100 ms)

Flashes when simulating a rich fuel condition

Flashes when simulating a lean fuel condition

Test leads connected to heater wire(s) or circuit with more than 6 Vdc

Overload current was detected when simulating Rich or Lean

Reverse polarity detected: to correct reverse test lead connections

Open circuit detected: check for loose connections

Ground connection detected: check test leads connections

Flashing indicates low battery: replace battery

This message will display momentarily when selecting the demo mode

3.2 Displays Description

3.2.1 Analog bargraph description

Real time signal

Displays the actual signal voltage output of the

oxygen sensor in real time.

Maximum

Displays the maximum voltage reached by the

signal (updated every new cycle).

Minimum

Displays the minimum voltage reached by the

signal (updated every new cycle).

Average

Displays a calculated time average of the oxy-

gen sensor output, in order to detect rich or lean

working conditions (updated every new cycle).

Maximum

Real time signal

Average

Minimum

.

•

If no crossings (cycles) of the input signal are detected for more than 10 sec-

onds or if the input voltage is out of range, only the real time signal indicator will

be displayed.

•

If the input signal exceeds the display range of the bargraph, only a flashing

dot will be shown at the top of the bar for an overvoltage and at the bottom for

an undervoltage condition. This could happen, if for example, the test leads are

connected to the sensor with the polarity reversed, or if the instrument is set for

Zirconia sensors, but connected to a Titanium 5 Volt system.

Fig. 1 - Instrument description

Fig. 2 - Bargraph description

1

3

2

4

6

8

5

7

9