SPP Pumps Thrustream - Extended User Manual

Page 20

Manual No/Rev

W12-005E / 3

Operators Instructions for Horizontal

Extended Thrustream Centrifugal Pumps

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 18 of 28

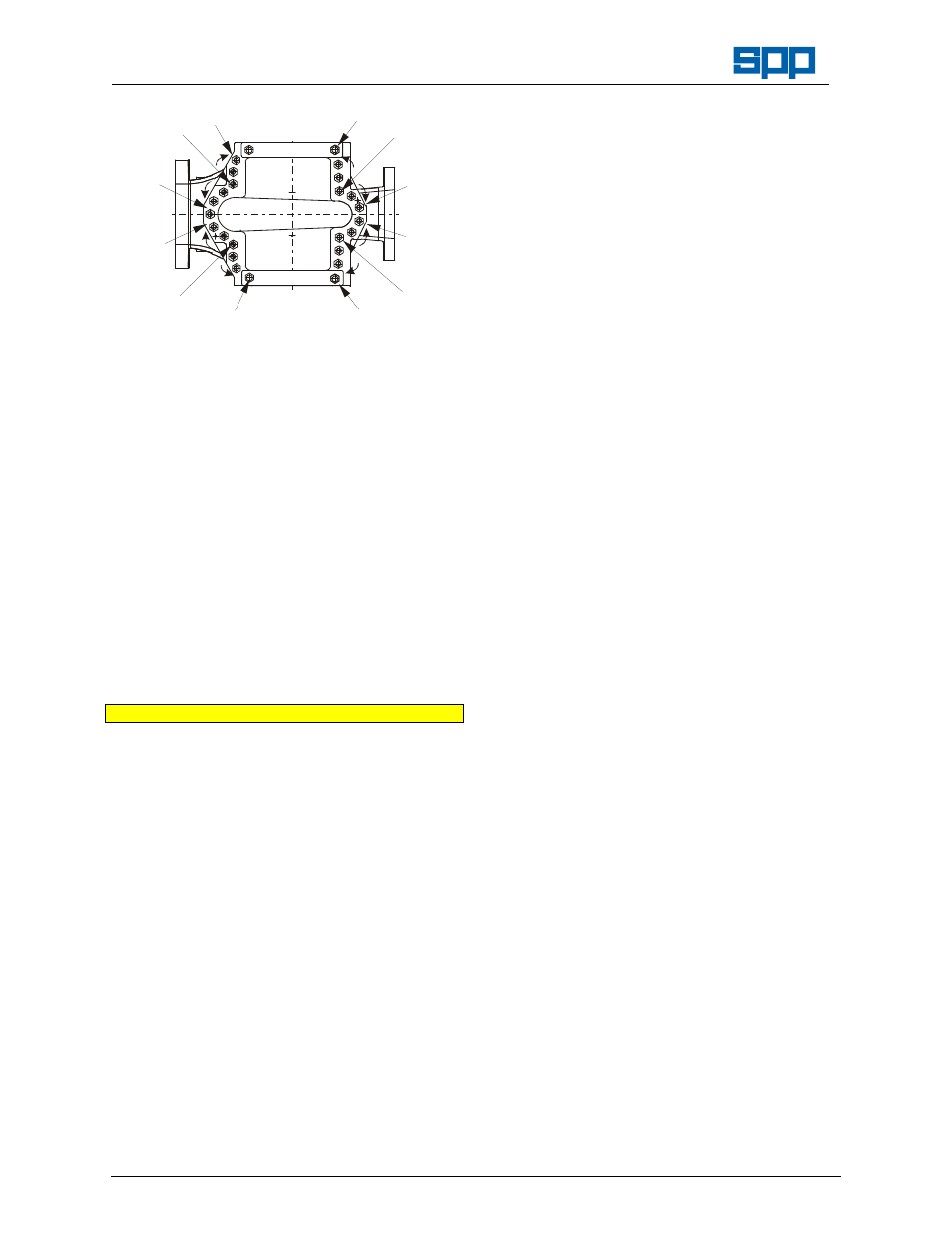

1

2

3

4

6

8

7

5

9

10

11

12

a) Tighten the four 'corner' screws marked 1,

2, 3 and 4.

b) Work outward along shaft axis toward the

stuffing

boxes

in

opposite

quarters

tightening screws in regions 5, 6, 7 and 8.

c) Work outward along the branch and in

opposite quarters tightening screws in

regions 9, 10, 11 and 12.

d) Repeat the whole sequence (a to d).

29. Check that the shaft turns freely by hand.

30. Top up the bearing lubrication by applying

several strokes with a grease gun.

31. The pump is now ready for re-coupling to the

motor and re-commissioning.

Two Stage Pump Assembly Instructions

Note: Two stage pumps are similar in construction

to the single stage pump and instructions

relating to maintenance and repair apply

equally to both types.

The difference relates to the disassembly of

the two impellers (A21 & B21) and the

interstage plate (8).

Proceed to disassemble the rotating assembly

as for single stage pumps to paragraph 10:

For Counter Clockwise pump construction:

16. Using a suitable ‘C’ spanner, unscrew and

remove the non-drive end sleeve (B47) on a

soft packed pump or impeller nut (A21) when

a mechanical seal is fitted.

For Counter Clockwise pump construction:

17. Using a suitable ‘C’ spanner, unscrew and

remove the drive end sleeve (A47) on a soft

packed pump or impeller nut (B21) when a

mechanical seal is fitted.

Note Light tapping with a soft faced mallet may be

needed to free the impeller from the shaft, do

not damage the impeller if it is to be reused.

1. Using suitable pullers or levers, slide the first

impeller (A21) of the shaft (71).

2. Withdraw the interstage plate (8) from the

impeller spacer (17) and check the condition

of the interstage neck bush (24) replace if

worn.

3. Tap and pull the other impeller (B21) off the

shaft with the impeller spacer (17).

4. Withdraw the impeller key (116) and unscrew

and remove the locked sleeve (A47) or the

impeller nut (B21).

Impeller re-assembly:

Proceed with shaft assembly as for single

stage pumps to paragraph 3.

1. Select the first impeller for assembly, check

the impeller for correct direction of rotation

and slide onto shaft to abut the locked sleeve

or nut.

2. Fit new O rings to each side of the impeller

spacer (17), slide on to the shaft and fit the

interstage plate (8) complete with its’ O ring,

ensuring that it is the correct way round to fit in

the pump casing.

3. Screw free impeller locking nut (A21) or

sleeve (B47) onto shaft to retain the impellers

against the locked impeller nut or sleeve.

4. Slide the casing wear rings (23) onto the

impeller.

5. Check that the dowels (8A) that retain the

interstage plate are correctly fitted.

Continue with pump re-assembly from

paragraph 7.