Troubleshooting guide – Poweramp RAIL RAMP SPECIALTY 1.1995 User Manual

Page 22

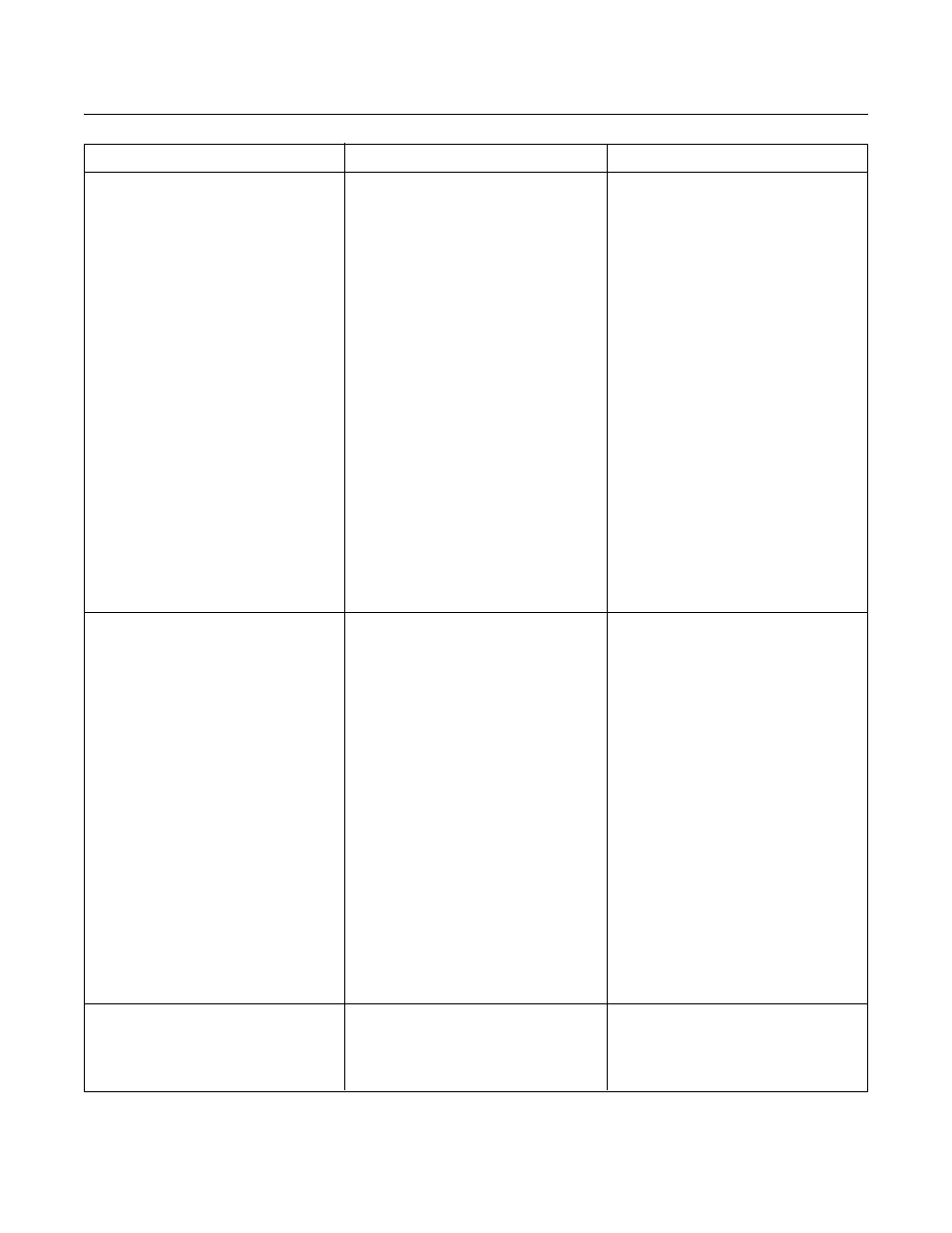

Problem

Cause(s)

Solution(s)

19

Railramp does not operate. Motor

energizes but does not run (motor

hums, overload device should trip).

1. 3 phase units only--voltage at

one line is absent (motor being

single phased).

2. 1 phase units only--motor

centrifugal switch faulty.

1A. Fuses at motor branch circuit

overcurrent device only--check

for tripped fuse. Replace

fuse. Determine cause of

fuse tripping.

1B. Check motor starter for

component failure. Discon-

nect wires at load side of

starter. Use voltmeter to read

line-to-line voltages at line

side and load side of starter.

Line side and load side

voltage values should be

nearly identical. Replace

starter if values are not

identical.

1C. Check all wiring to motor for

high resistance (loose) or no

connection.

2.

Replace motor.

1. Add fluid, see Preventative

Maintenance section, page 15.

2. Locate pressure relief valve.

Turn valve 3/4 turn (CW).

Increase the valve set point until

the Railramp operates properly.

NOTE: The valve set point

should NOT be set at a level

that will cause the motor

operating current to exceed its

full load amp value at any time,

including when the unit is

operated in pressure relief.

3. Replace damaged hose(s).

Remove blockage from hose(s).

1. Low hydraulic fluid.

2. Pressure relief valve set too low.

3. Damaged or blocked hydraulic

hose(s).

Railramp operates slowly.

1. Add fluid. See Preventative

Maintenance section, page 15.

1. Low hydraulic fluid.

Railramp does not fully raise or

motor overcurrent device and/or

overload device continuously tripping.

Troubleshooting Guide