Troubleshooting guide – Poweramp CHALLENGER HYDRAULIC 11_96 User Manual

Page 18

Always barricade the work area to prevent unauthorized use of the unit during repair or mainte-

nance procedures.

Always lock OFF all electrical disconnects when servicing the unit. Always stand clear of the

dockleveler lip when working in front of the unit.

Perform the following procedures prior to beginning detailed troubleshooting:

A. Check all fuses inside the control assembly(s). Replace any bad fuse with one of

equivalent specification.

B. Confirm presence of necessary voltages inside the control assembly(s).

WARNING

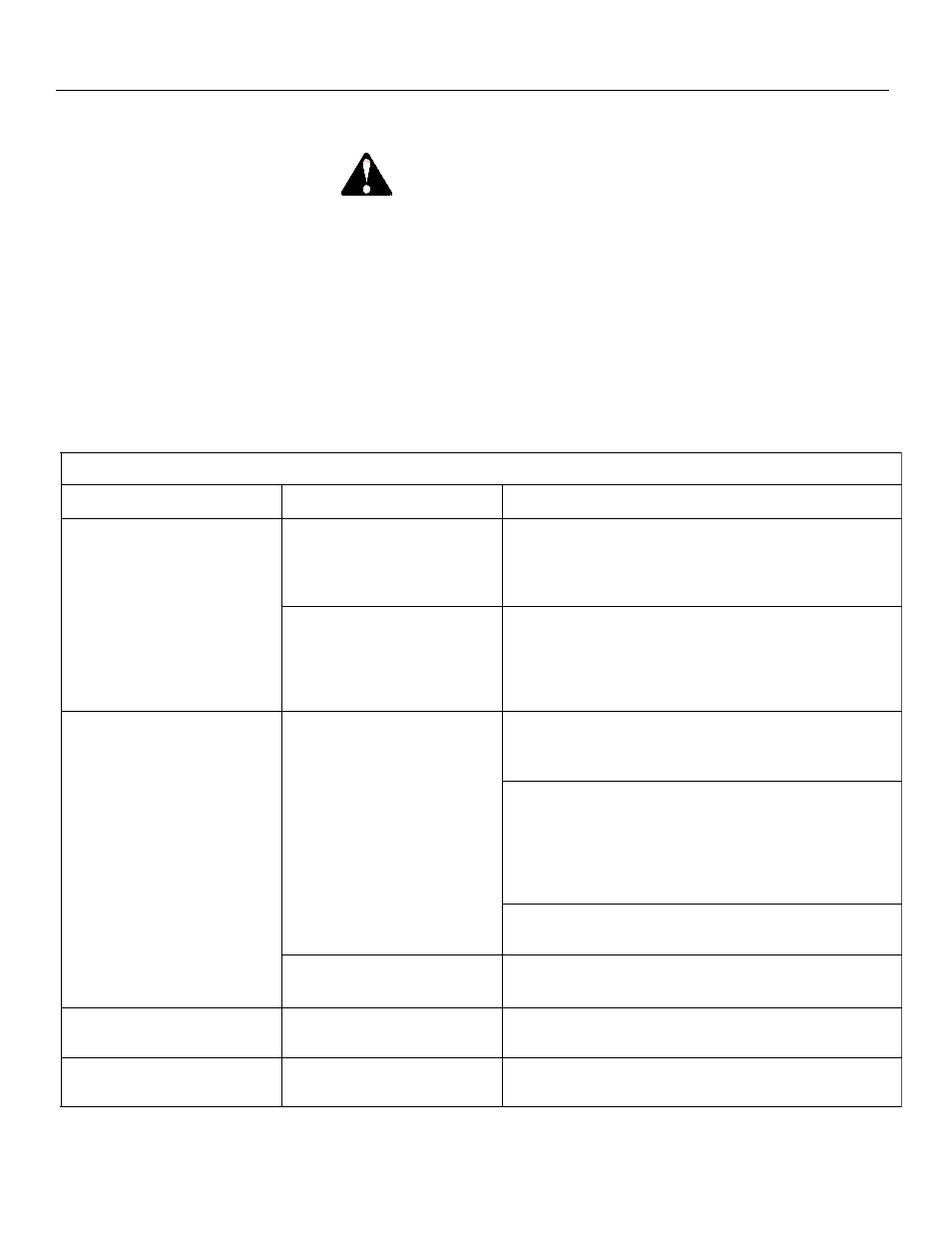

TROUBLESHOOTING GUIDE

17

DOCK LEVELER

Problem

Cause(s)

Solution

Leveler does not operate.

Motor does not energize

1. Motor overload device

tripped.

1. Reset Overload relay (3 phase) or replace fuse(s) (1

phase). Determine cause of device tripping. NOTE: If

replacing fuse(s), replace with device of equal

specifications.

2. Motor starter (3 phase) or

motor relay (1 phase) not

energizing.

2. Check voltage at starter or relay coil. If voltage is

present and starter or relay does not energize then

replace device. If voltage is not present check all

components in series with the starter or relay coil for

proper operation.

Leveler does not operate.

Motor energizes but does not

run (motor hums, overload

device should trip).

1. 3 phase units only - voltage

at one line is absent (motor

being single phased).

1A. Fuses at motor branch circuit overcurrent device only

- check for tripped fuse. Replace fuse. Determine cause

of fuse tripping.

1B. Check motor starter for component failure.

Disconnect wires at load side of starter. Use voltmeter to

read line-to-line voltages at line side and load side of

starter when starter is energized. Line side and load side

voltage values should be nearly identical. Replace starter

if values not identical.

1C. Check all wiring to motor for high resistance (loose)

or no connection.

2. 1 phase units only - motor

centrifugal switch faulty.

2. Replace motor.

Leveler will not raise. Pump

operates in pressure relief.

1. Load on platform.

1. Remove load. Unit is designed to raise no more than its

own weight as a safety feature.

Leveler operates slowly.

1. Low hydraulic fluid.

1. Add fluid. See Preventive Maintenance section, page

14.