Adjustment and testing – Poweramp CHALLENGER HYDRAULIC 11_96 User Manual

Page 11

ADJUSTMENT AND TESTING

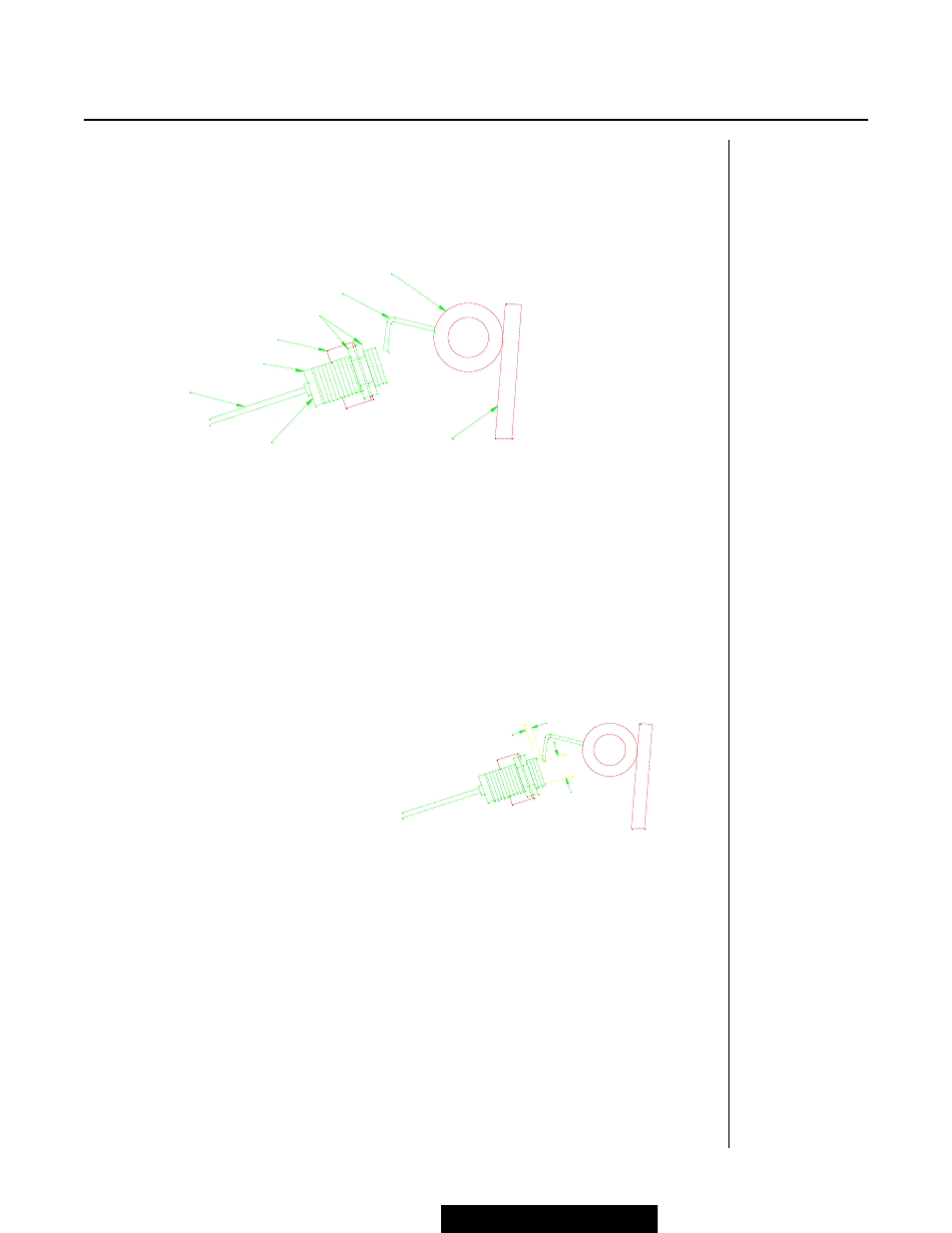

Your dockleveler may be equipped with Auto Return to Dock. Auto Return to Dock

is an option available on Challenger series dock levelers that will automatically

reposition the dockleveler into the stored, cross traffic position after the truck de-

parts. This option utilizes a switch under the dock leveler and a target fastened to

the lip. See Figure 13.

Figure 13

LIP HINGE TUBE

TARGET

LOCK NUTS

PROXIMITY SWITCH

INDICATOR LIGHT*

BRACKET

LIP

COMPONENT IDENTIFICATION

Typical factory settings for dimensions "A" & "B"

are approximately 1" & 1/4" respectively. The

values for dimensions "A" & "B" for this applica-

tion may be different than the typical factory

settings. The switch and/or target are to be

adjusted to obtain the results indicated in figures

15 through 17 below. Dimension "A" can be

changed by bending the target. Dimension "B"

can be changed by moving the switch in the

bracket.

IMPORTANT: Work lip by hand when making

adjustments to make sure that the target does

not make contact with switch. Damage to

switch will ocur if target contacts switch.

IMPORTANT: Maximum tightening torque for

lock nuts is 27 N-m (20 FT-LBS). Damage to

switch will occur if maximum tightening torque

is exceeded.

B

A

LIP FULLY

F O L D E D

* Figure 13 shows the indicator light at the back end of the housing. Some

switches have the light in the side of the housing.

Figure 14

10

CABLE