Gas supply pipe sizing and looping – Alliance Laundry Systems Drying Cabinet User Manual

Page 34

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Gas Requirements

70304601

32

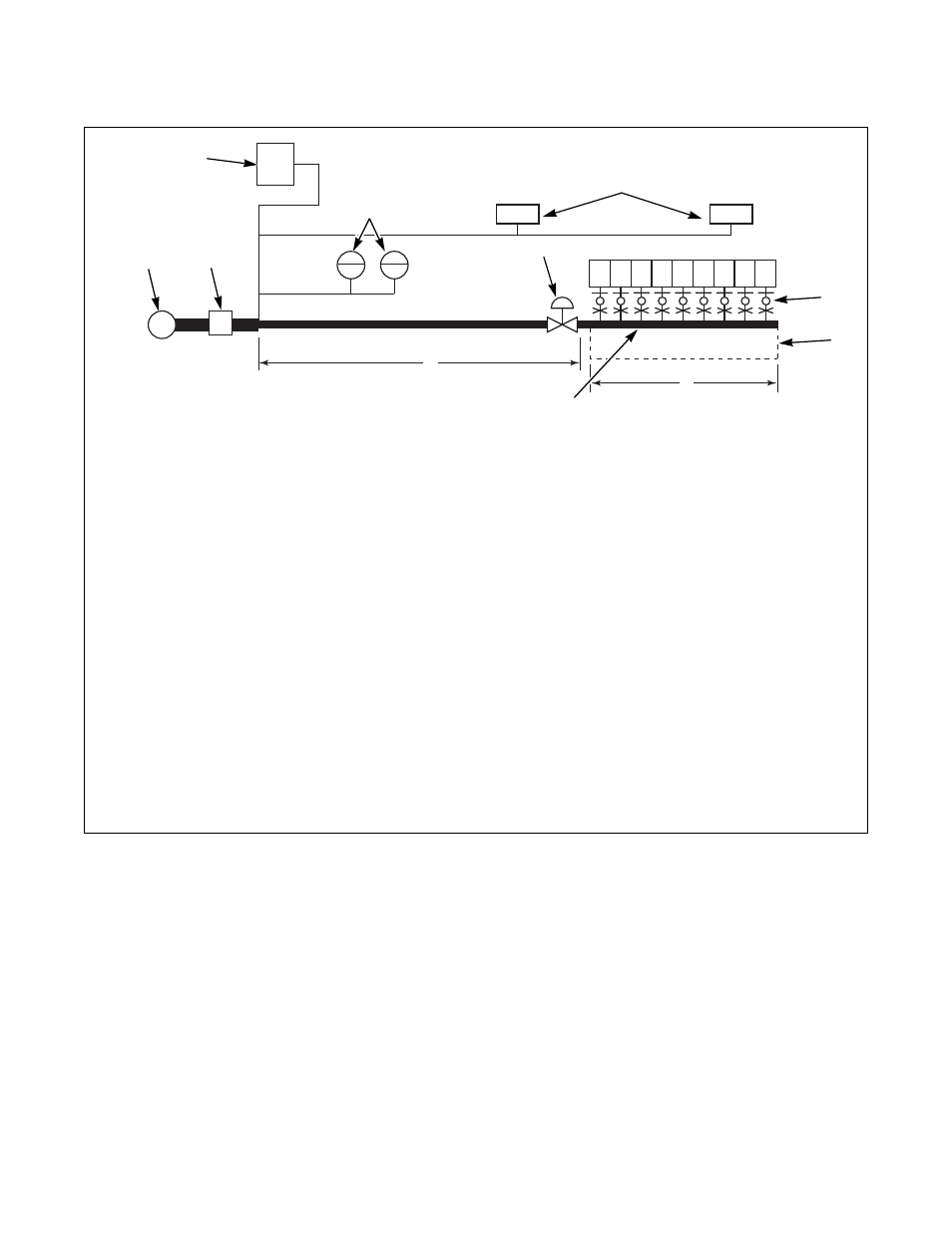

Gas Supply Pipe Sizing and Looping

Figure 13

TMB2126N

1

Gas Furnace (120,000 Btu/hr.)

8

25 ft. (7.6 m)

2

Gas Water Heaters (400,000 Btu/hr. each)

9

Main Regulator

3

Gas Space Heaters (70,000 Btu/hr. each)

10

Gas Meter

4

Sediment Traps, Supply Pressure Taps and

11

Pressure Regulator (if required)

Shut-off Valves. Refer To Figure 12.

12

T30 Tumblers (73,000 Btu/hr per pocket;

5

1 in. (25.4 mm) Gas Pipe Loop

146,000 total Btu/hr for machine)

6

19 ft. (5.8 m)

T45 Tumblers (95,000 Btu/hr per pocket;

7

Minimum Pipe Size is 0.5 in. (12.7 mm)

190,000 total Btu/hr for machine)

SAMPLE CALCULATIONS:

Equivalent length

= Total length of main gas supply pipe to the far end of the tumblers.

= 25 ft. + 19 ft. (7.6 m + 5.8 m) gas supply pipe

= 44 ft. (13.4 m) Total Gas Line

Total Btu/hr.

= The sum of the Btu/hr. of all T30 tumblers being fed by the main gas supply pipe.

= 9

x

73,000

= 657,000

Btu/hr.

Using Table 6, the main supply pipe diameter should be 2 in. (51 mm).

IMPORTANT: Gas loop piping must be installed as illustrated to equalize gas pressure for all tumblers

connected to single gas service. Other gas using appliances should be connected upstream from loop.

1

2

3

4

5

6

7

8

9

M

9

12

8

6

3

2

1

10

11

7

5

4