Nova-Tech LMI Series G - SD Metering Pump User Manual

Page 45

SECTION 6

TROUBLESHOOTING

45

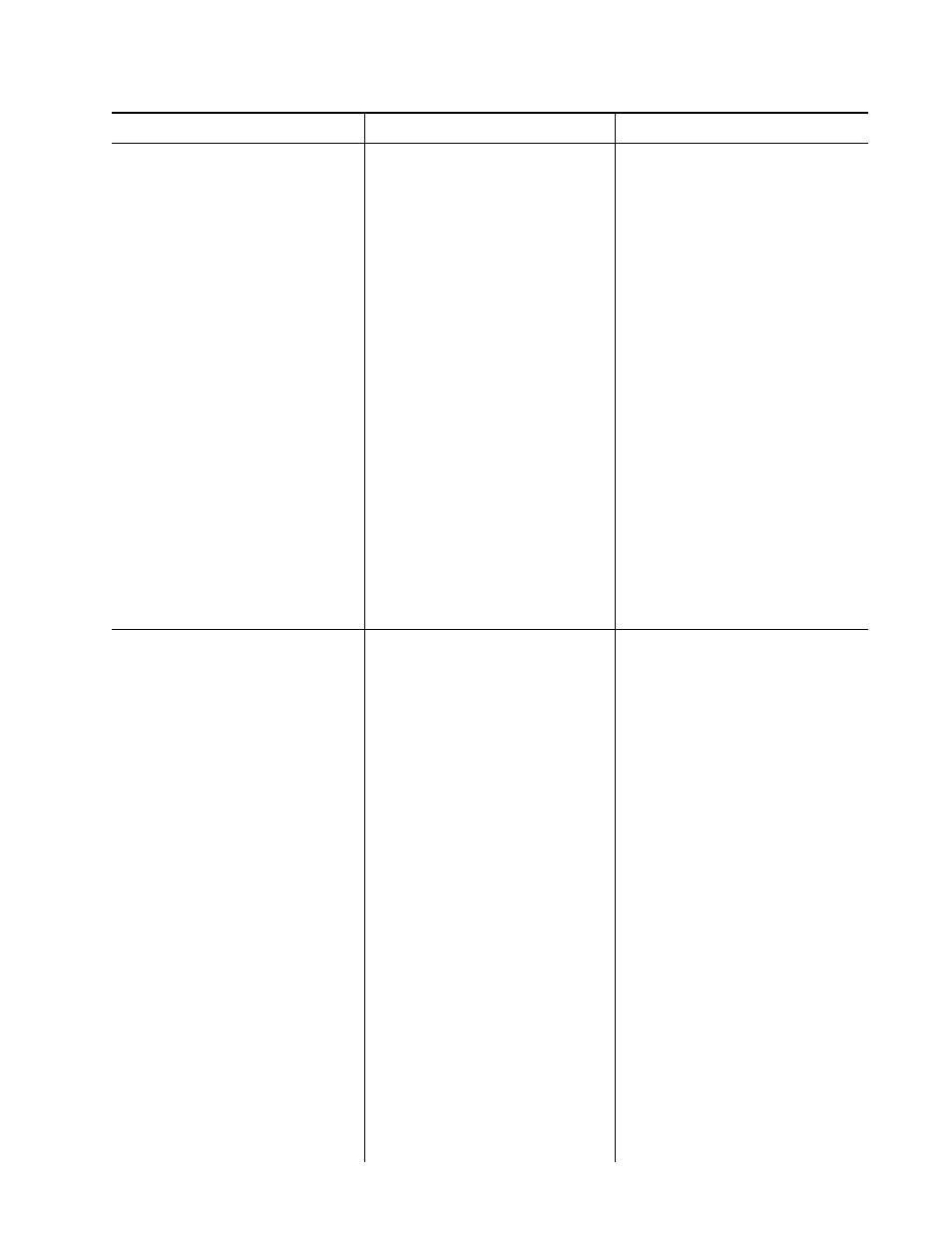

1. Pump motor won't operate.

2. Insufficient pump delivery.

SYMPTOMS

POSSIBLE CAUSE

REMEDY

a) Low process liquid level in the

tank.

b) Worn or dirty check valves.

c) Blocked discharge line.

d) Frozen liquid.

e) Blown fuse.

f) Open thermal overload device in

motor starter.

g) Broken wire.

h) Low voltage.

i) Pump not primed.

j) Capacity adjustment set at zero.

a) Incorrect capacity adjustment.

b) Incorrect pump speed.

c) Starved suction.

d) Leaky suction piping.

e) High suction lift.

f) Liquid near boiling.

g) Leaky safety valve in discharge

line.

h) High liquid viscosity.

i) Worn or dirty check valve seats.

a) Add liquid.

b) Clean or replace.

c) Clear line.

d) Thaw liquid throughout pumping

system.

e) Replace fuse.

f) Reset device.

g) Locate and repair.

h) Investigate and correct (wiring

may be too tight).

i) Allow suction line and pump

head to fill with liquid before

pumping against pressure.

j) Readjust capacity.

a) Readjust capacity setting.

b) Match line voltage and frequency

to pump motor data plate.

c) Increase piping size or suction

head.

d) Repair piping.

e) Rearrange equipment to de-

crease lift and/or install foot valve

in suction line.

f) Cool liquid or increase suction

head.

g) Repair or replace valve.

h) Reduce viscosity (e.g., heat or

dilute liquid), or consult the

factory for special check valve

options.

i) Clean or replace.

39