Discontinued, Installation - model 294, Mechanical installation – Max Machinery 294_269 High Resolution, Linearized Frequency Transmitters User Manual

Page 6: Electrical installation - wiring, Frequency single phase, Frequency quadrature

6

Mechanical Installation

1. Attach transmitter to the threaded magnet shield on top of the flow meter. Hand tighten. (~ 3 ft - lb)

1

2. If necessary, loosen set screws on the transmitter’s cap and rotate to align cable as desired.

3. Ensure cap is firmly pushed down to seal O-ring. Tighten set screws.

Removal

1. Remove electrical connections

2. Unscrew transmitter, using a wrench if necessary.

Removal note: The transmitter does not need to be removed from the flow meter for any field servicing or adjustments.

Normally, the flow meter and transmitter are shipped back to the factory for calibration or service as a unit. If the

transmitter needs to be removed from the flow meter for installation, be sure to retighten the transmitter snugly in order

to seal the o-ring and to ensure proper sensor alignment.

Moisture Protection

On all models, the housing is designed as a liquid and vapor-tight enclosure. There are o-ring seals

at the lid and base of the housing – these both need to be fully seated. A properly sealed transmitter

will prevent the formation of damaging moisture inside the housing.

Turck connector Model: The connector is sealed to the lid at the factory and is ready for use.

NPT Model: To ensure a moisture-tight seal, apply appropriate sealant to the threads at installation.

1

Transmitter may be wrench tightened up to 15 ft - lb if it will be subject to vibration or loads. This additional torque

causes relative movement between transmitter and meter, so to ensure optimal performance, request that the factory

apply the extra torque before calibration / compensation, or run the compensation program in the field after tightening.

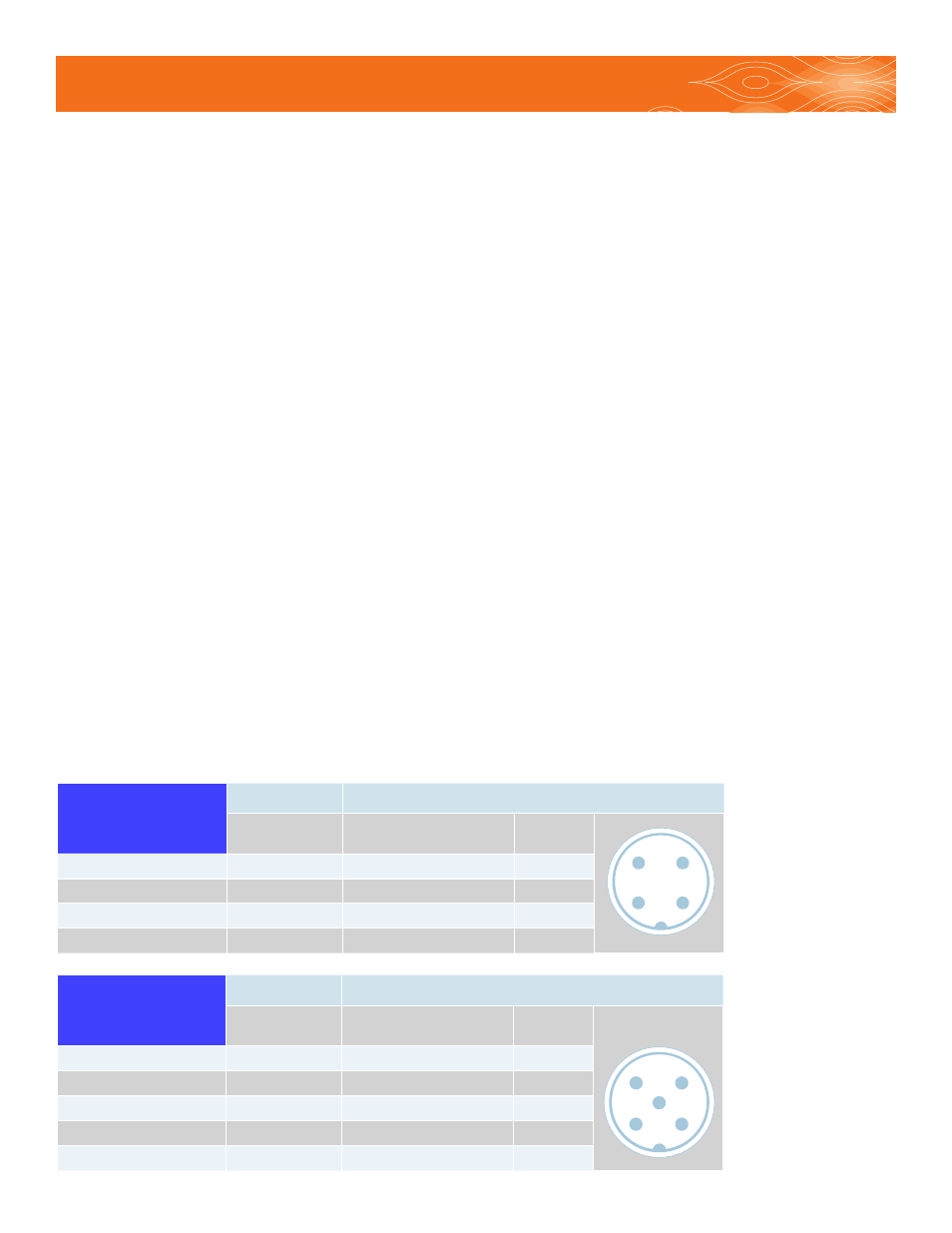

Electrical Installation - Wiring

The electrical connector versions are pre-wired inside the transmitter and ready to accept a mating

cable (available from the factory). The liquid-tight, NPT models need to be wired during installation

as shown in the table below:

an ISO 9001:2008 certified company

Installation - Model 294

NPT model

4-Pin Connector

Connector

Terminal #

Mating Cable

Wire Color

Pin #

Case Ground

In-lid

Blue

3

Common

1

Black

4

Power 5-26 Vdc

2

Brown

1

Pulse Output

3

White

2

2

1

4

3

Frequency

Single Phase

NPT model

5-Pin Connector

Connector

Terminal #

Mating Cable

Wire Color

Pin #

Case Ground

In-lid

Blue

3

Common

1

Black

4

Power 5-26 Vdc

2

Brown

1

Output Phase A

3

White

2

Output Phase B

4

Grey

5

2

1

4

5

3

Frequency

Quadrature

Discontinued