Mach III Clutch V8G1K-STL, V8G2K-STL User Manual

Page 5

7/9/2013

TORQLIM_MECH_W_COUPL_MANUAL

Page 5 of 5

B. Product Numbers: V6G1G-STL, V6G1H-STL, V6G2H-STL, V8G1K-STL,

V8G2K-STL and non-catalog variations of this torque limiter design.

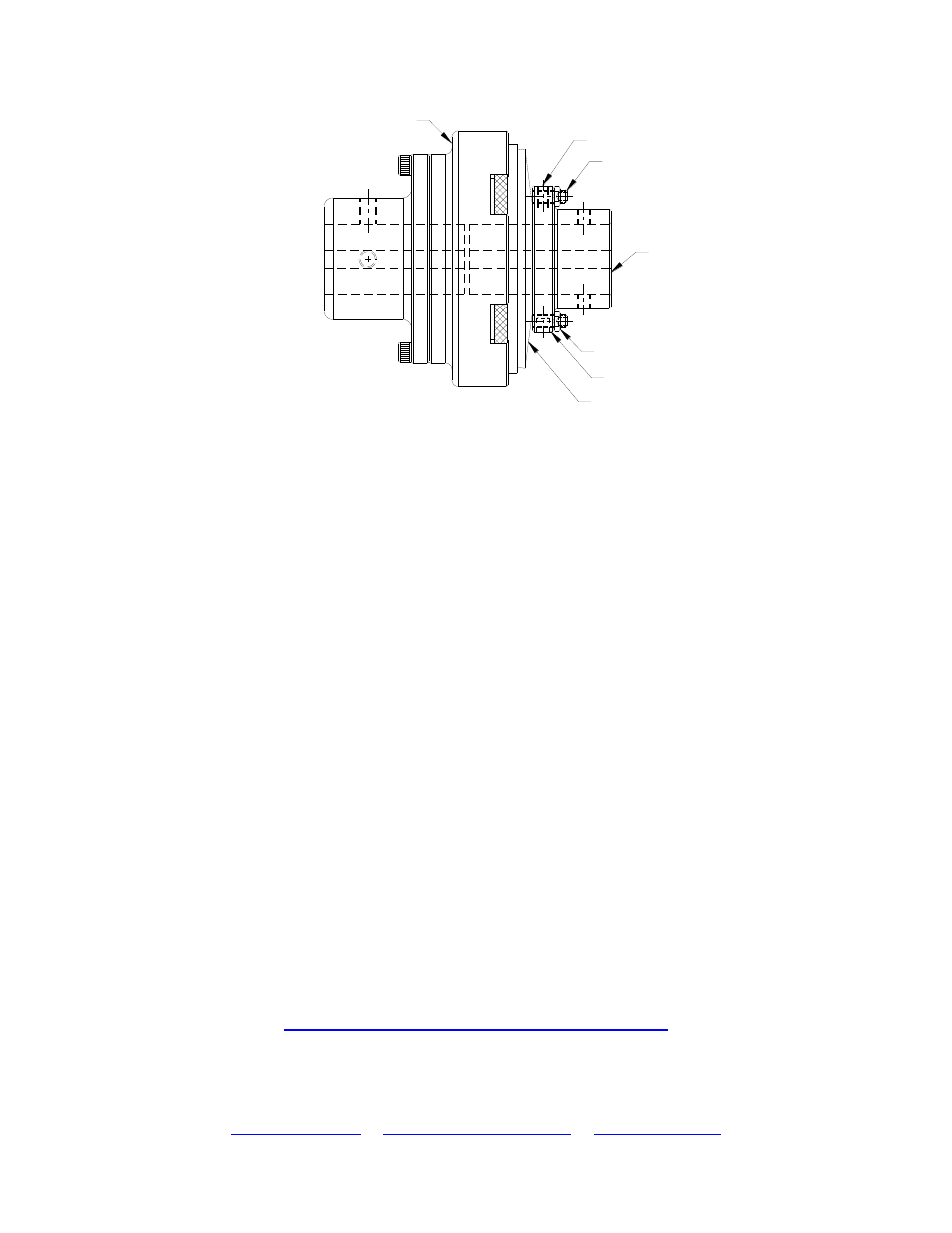

(1) Make sure the adjustment nut (REF. A) is snug against the disc spring (REF. B).

(2) Make sure the six jam nuts (REF. C) mounted on the six set screws (REF. D) which are placed

axially in adjustment nut (REF. A) are loose.

(3) Screw the six set screws (REF. D) in the adjustment nut (REF. A) until they contact the disc

spring (REF. B).

(4) Using a circular pattern, tighten the six set screws (REF. D) in the adjustment nut (REF. A) one

1/4-turn each.

NOTE: If needed, fine tune the torque value of the unit in 1/8-turn increments of the six set

screws (REF. D).

(5) Check torque value after each 1/4-turn increment of all six set screws (REF. D) while holding

adapter/sleeve (REF. F) stationary and turning drive hub (REF. G) with a torque wrench.

NOTE: A torque wrench with a multiplier may be needed for higher torque settings.

(6) Once desired torque is reached, confirm each of the six set screws (REF. D) are in contact with

the disc spring (REF. B).

(7) Tighten the jam nuts (REF. C) mounted on the six set screws (REF. D) firmly against the

adjustment nut (REF. A).

(8) Tighten the nylon-tipped set screw (REF. E) in the outside diameter of the adjustment (REF. A).

Technical assistance is available by contacting Mach III Clutch, Inc.

Mach III Product Warranty

Mach III Clutch, Inc.

101 Cummings Drive ● Walton, KY 41094

Toll free 866.291.0849 ● International 859.291.0849 ● Fax 859.655.8362

A

B

C

D

E

F

G