Laurel Metal 899 3-COLUMN ELECTRONIC VENDER User Manual

Page 2

E

LECTRICAL

H

OOK

-U

P

The 24 volt AC power connection for the machine is on

the circuit board of the coin mechanism. The terminal

block for incoming power is located on the lower left

corner of the circuit board. You will have to lift up the

cover/instruction sheet to locate this black terminal

block, which requires a small slotted screwdriver for the

2 lugs. Leave at least 24” of wire inside the vender to

simplify future coin mechanism programming.

BE CERTAIN TO SUPPLY 24 VOLTS/AC

T

RANSFORMER

P

OWER

R

EQUIREMENTS

The minimum power required for each vender is 1/2

amp (500mA). To run multiple venders on a transformer

first determine the total amperage required, taking into

account future additions. To determine the amperage

output of a 24 volt transformer that is given in VA, divide

the VA output by 24. For example, a 100 VA transformer

would provide 4.2 amps (100 ÷ 24) of 24 volts AC

power. This would be ample power for 8 venders.

I

NSTALLATION

Packed inside the carton pad at the top of the vender:

• 1 – Cabinet hangar bracket

• 1 – Bag of fasteners for the security frame

• 1 – Side bar - mounts on right side of cabinet

Mount the hanger bracket securely on the wall and note

that the top edge of this bracket will go inside the open

area at the back of the cabinet. Two people should lift

the vender to hang it on the bracket. Open the door and

note the two 3/8” diameter mounting holes in the lower

left and lower right sides of the cabinet. Remove the

coin mechanism to expose the right side mounting

holes. To remove the coin mechanism, first unplug the

white ribbon cable from the red switch pad and then

loosen the two mounting screws (you do not need to

remove these screws) and lift the coin mechanism

upward to detach. There are two wire harnesses to

unplug from the back of the coin mechanism. Now

select desired mounting holes and mark the holes,

remove vender, drill and install appropriate anchors.

Re-hang the vender and secure the lower fasteners.

P

RODUCT

L

OADING

The shelves can be easily and quickly reset into the vend

position (horizontal) by running a finger or thumb up the

shelves from the bottom to the top. This ‘fanning’ will

take only seconds to reset all shelves. When loading any

column, if there is not enough product to fill all 24

shelves, then load from top down. This insures that the

sold-out switch will activate when the last shelf (the top

shelf) drops. If a customer chooses a selection that is

empty, the display will flash & and return

the inserted coins.

2

7

T

ROUBLE

S

HOOTING

LED display out: power loss, check for 24 volts (+ - 15%)

at the terminal block of the Circuit Board. Power down for

5-10 seconds and power back up. If the display is still out

then simultaneously press the

UP & DOWN buttons on

the Circuit Board to clear any error codes. If this fails the

Circuit Board is in need of repair.

LED display is not alternating: this indicates a short in the

Switch Pad or the Ribbon Cable. First, disconnect the

Ribbon Cable from the Switch Pad and if the LED display

returns to alternating, the problem is a short in the Switch

Pad. If the display still is not alternating then unplug the

Ribbon Cable from the Circuit Board to check if the short

is in the Ribbon Cable. Call the factory for information on

how to disable a shorted switch, which will get the

machine back working, less the bad switch.

Inserted coins rejected: power loss, MA800 acceptor

needs reprogramming, wrong type of coin inserted, accep-

tor not plugged into back of circuit board, change sample

coin in Slugbuster. If a column is sold out or the exact

amount was not inserted, then coins will be returned to the

customer after a selection button is pressed.

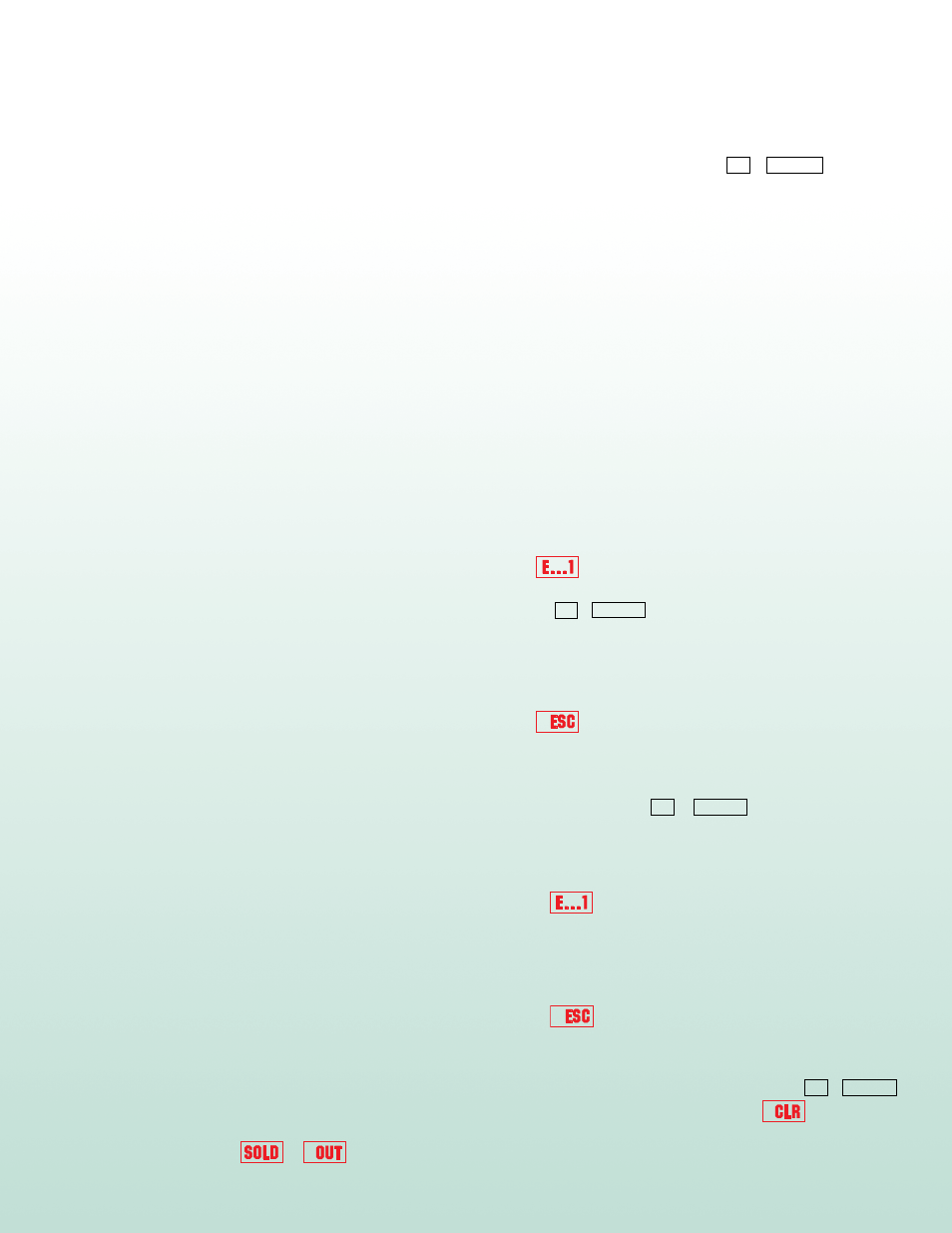

displayed: a vend motor for a column is not

working properly. To reset and test, simultaneously press

the

UP & DOWN buttons on the Circuit Board. If this fails

then remove the column from the machine and visually

inspect the motor and wiring. The motor may be out of

alignment or lubrication may be needed between the

motor cam and the shelf flanges.

displayed: the coin cup motor is not working

properly. Remove the Coin Mechanism to visually inspect

the motor for coin jams, etc. The coin cup can be manu-

ally rotated to test its operation. To reset and test, simulta-

neously press the

UP & DOWN buttons on the Circuit

Board until CLR appears on the display. Powering down

& up will reset the coin cup in the upright position.

E

RROR

M

ESSAGES

•

There is a problem with the vend motor

assembly of a column and this column will not function. If

this selection button is pressed after coins have been insert-

ed, the coins will be returned to the delivery tray. The other

columns will not be affected.

• There is a problem with the coin-cup motor

(the escrow cup) and the machine will return any inserted

coins until the problem is resolved.

To clear any error messages, either press the

UP & DOWN

buttons simultaneously and wait for to appear on

the display or power down the machine for 10 seconds

and power back up. Refer to the trouble shooting section

to correct the problem.