Ii - performances – Continental Industrie Model - 251 User Manual

Page 4

Values, dimensions and reference in this brochure are approximate and intended as guide only, not for construction and are subject to change without notice

DETAILED ENGINEERING DESCRIPTION - CONTINENTAL INDUSTRIE

DEB251EN – 04/2010

4/4

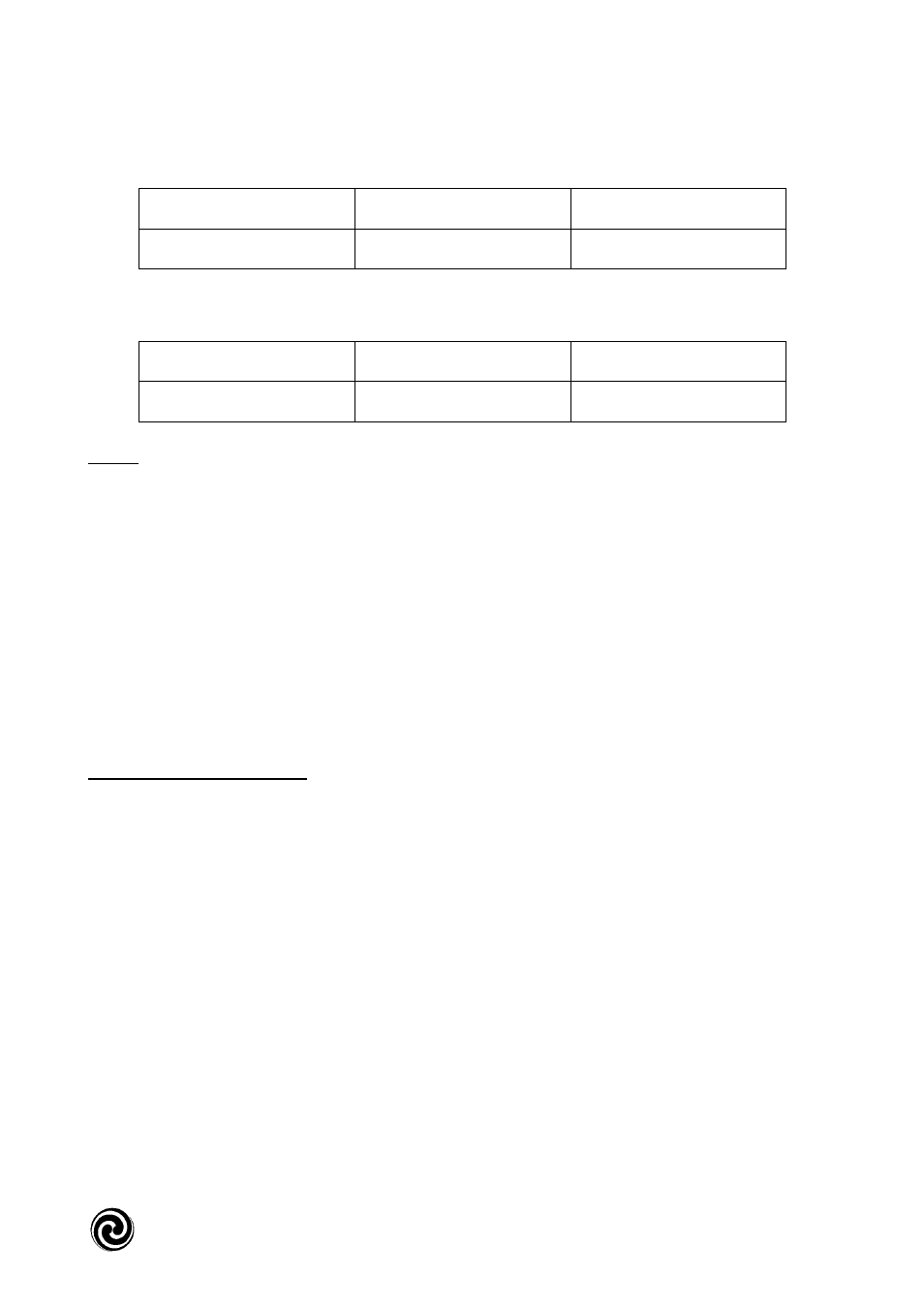

13.0 Recommended maximum allowable Piping forces and moments on blower

connections

13.1 Inlet flange

FX = 70 KG

FY = 175 Kg

FZ = 140 Kg

MX = 105 kgm

MY = 52 kgm

MZ = 52 kgm

13.2 Outlet flange

FX = 70 KG

FY = 175 Kg

FZ = 140 Kg

MX = 105 kgm

MY = 52 kgm

MZ = 52 kgm

where :

F = force

M = moment

X = Axial - parallel to rotor centre line

Y = Vertical

Z = Horizontal - normal to rotor centre line.

14.0 Vibration and noise

Vibration tolerance: 4,5 mm/s RMS

Vibration shall not exceed 4,5 mm/s RMS when measured in the vertical plane at the

bearing housings with the blower operating at the design speed.

Sound level: please refer to the calculation data sheet

II - PERFORMANCES

1.

All tests if required are in conformity with ASME Power Test Code.

2.

For constant speed blowers:

- The head shall be within the range of 100% - 105% of the normal head at design capacity,

- The horsepower based on measured head shall not exceed 107% of the value at the specified

normal operating point.

3.

For variable speed machines:

- through the rotational speed, the head shall be adjusted as close as possible to the design point,

with zero negative tolerance,

- the horsepower at that point shall not exceed 104% of the predicted shaft power value.