Frequent & periodic inspection chart – CM-ET Series 603 User Manual

Page 5

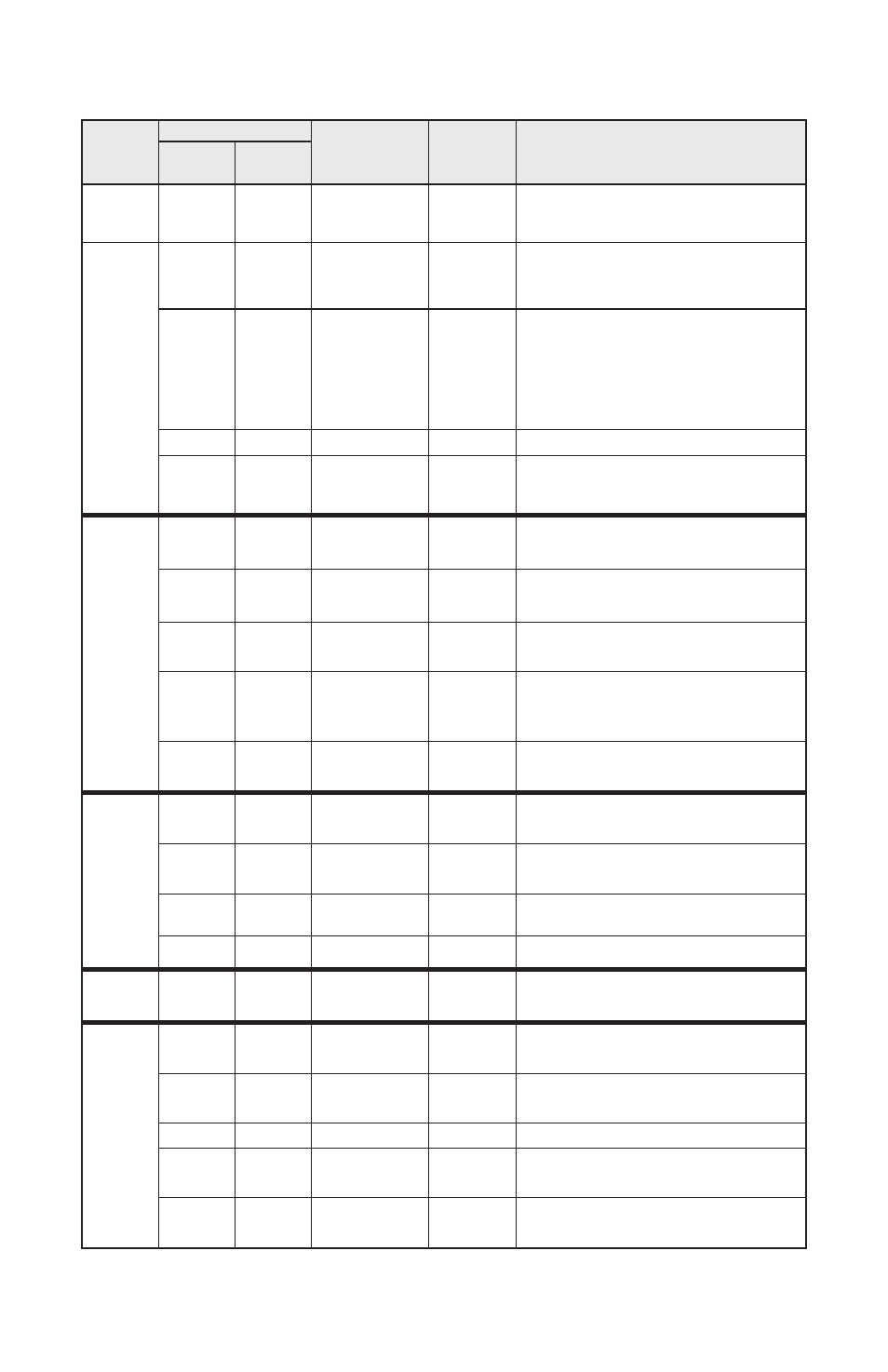

FREQUENT & PERIODIC INSPECTION CHART

*Daily or before each use.

ITEM

FREQUENCY

WHATTOCHECK

INSPECTION

METHOD

ACCEPTANCELEVEL

DAILY

(FREQUENT)*

EVERY6

MONTHS

(PERIODIC)

LABELING

&TAGS

X

X

Nameplate,

capacity label

warning labels &

free chaining tag

Visually

These items must be legible and securely

fastened to the hoist. Replace if necessary.

OPERATION

X

X

General

Operation

Lift & lower

a light load

1. Chain must feed into and out

of the hoist freely.

2. Brake must hold the load when handle

is released.

– – –

X

Overload test

Lift & lower

a 688 lb.

(312 Kg.) load

for the 602

or a 1378 lb.

(625 Kg.) for

the 603 one

foot (300 mm)

1. Pull on handle should be about 73# (33Kg.)

2. Brake should operate smoothly

while lowering.

X

X

Directional Lever

Movement

Lever must move smoothly.

X

X

Free Chaining

Movement

In free chaining mode, chain should feed into

and out of the hoist freely when pulled by hand.

HOOK

ASSEMBLIES

X

X

Hook opening

& bowl wear

Measure

opening and

bowl wear

See Figure 4.

X

X

Hook latch

Operation,

engagement

& damage

1. Latch must not be damaged.

2. Latch must operate smoothly with sufficient

pressure to engage the tip of the hook tightly.

X

X

Hook

deformation

Visually

Hook must not be bent more than

10 degrees from the plane of the unbent hook.

X

X

Hook chain screw,

upper hook pin,

hook collars and

hook collars

hardware

Visually

There must be no damage,

corrosion, excessive wear or looseness.

X

X

Hooks, chemical

damage, cracks,

gouges

Visually

There must be no excessive cracks,

corrosion, visible cracks or gouges.

CHAIN

X

X

Lubrication

Visually

Chain should be frequently

lubricated using Frisk Bros.

Lubriplate 10-R, or equal.

X

X

Corrosion, Pitting,

Gouges

Visually

There must be no excessive corrosion,

pitting or gouges on the chain.

X

X

Wear &

Contamination

Measure

chain for wear

& stretch

See figure 5.

X

X

Deformation

& Twists

Visually

Chain must be free of twists.

BRAKE

DISC

– – –

X

Wear &

Contamination

Measure

thickness

& visually

Take the hoist out of service if the thickness

is less than 0.094” (2.4 mm) or if the friction

surfaces are glazed, oily or contaminated.

HOIST

HEAD

– – –

X

Side plate

& Covers

Visually

Frame and covers should not be damaged

or corroded.

X

X

Handle

Visually

Handle must not be bent or corroded.

Grip should not be damaged.

– – –

X

Stripper

Visually

Stripper must not be bent, corroded or worn.

X

X

Hardware

Visually

All nuts must not be corroded

and must be securely tightened.

– – –

X

Pawl & Ratchet

Visually

There should be no excessive wear of the

ratchet teeth and the tip of the pawl. The pawl

spring should not be corroded or stretched.

Series 602/603 Operating, Maintenance & Parts Manual

5