Locked brake, Maintenance/inspection, Figure 2 – CM-ET Series 603 User Manual

Page 4: Figure 4 figure 3, Figure 5

LOCKED BRAKE

If a hoist under load is suddenly relieved of the load by removing the load from the hoist by some other

means, the brake will remain locked. The brake could also lock if the lower hook block is run tightly

against the frame. To unlock the brake, move the directional lever to the (

) UNLOAD position and pull

sharply on the handle, or reapply the load and operate the hoist in the normal manner.

MAINTENANCE/INSPECTION

The Series 602/603 Lever Hoist normally requires very little maintenance, other than the frequent and

periodic inspection listed in the chart on page 5. However, if the hoist is disassembled for inspection,

the following should be observed when reassembling.

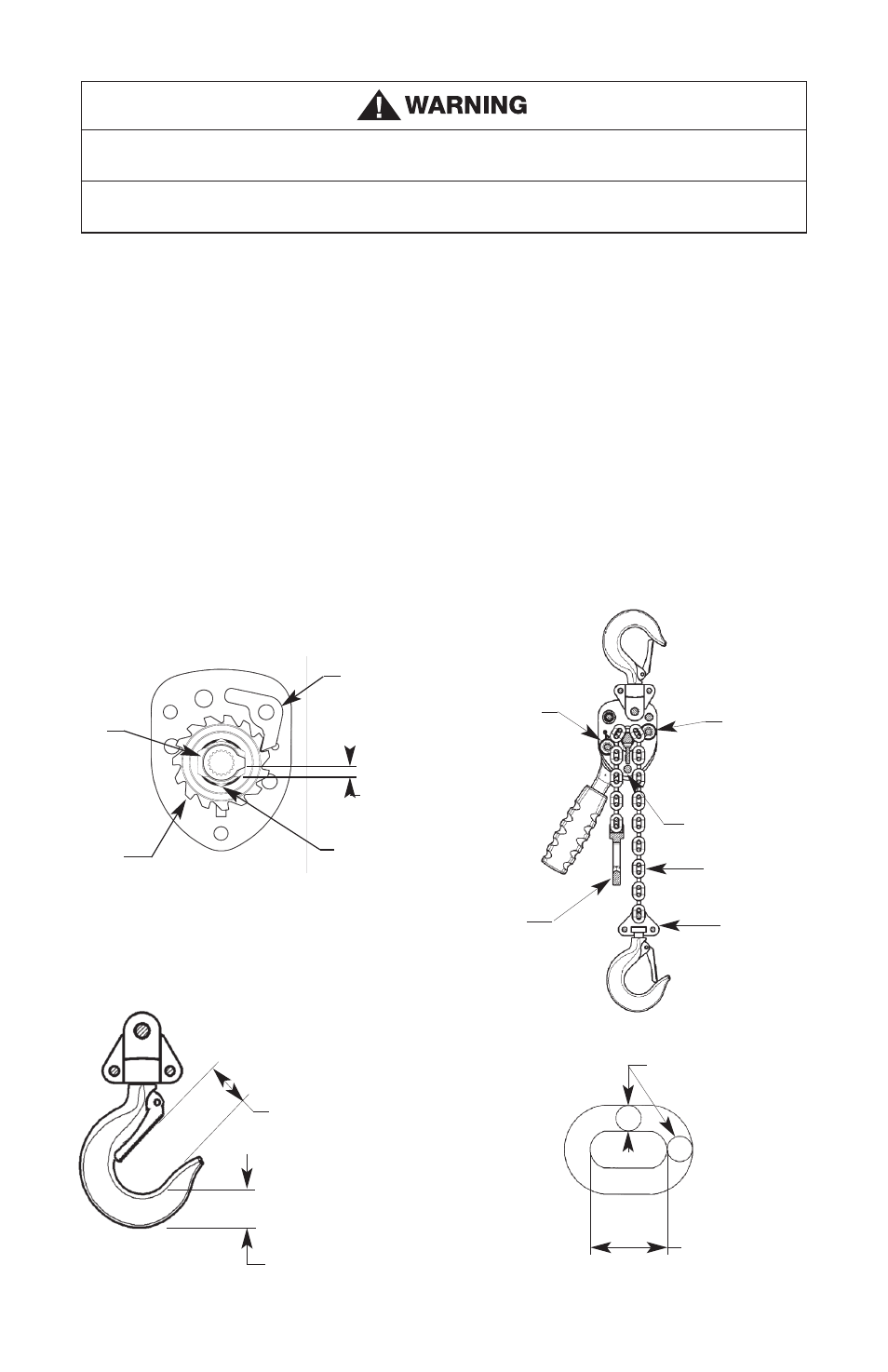

1. The pawl must engage the teeth of the ratchet as shown in Figure 2.

2. The check washer must be positioned on the ratchet hub as shown in Figure 2.

3. When installing the chain, it must be fed through the chain guide rollers with the welds away

from the liftwheel, the lower hook must be directly below the upper hook and the loose end ring

must be positioned and oriented at the end of the chain as shown in Figure 3

4. A rivet is used to attach the latch to the hook. To remove the latch grind off the head of the rivet.

When installing the latch, only peen over the end of the rivet enough to secure it.

If directional lever is forced out of engagement with a load applied, load will be released.

PAWL

1

/8"

RATCHET

PAWL

RATCHET

CHECK

WASHER

FIGURE 2

CHAIN GUIDE

ROLLER

CHAIN GUIDE

ROLLER

STRIPPER

LOAD CHAIN

WELDS AWAY

FROM LIFTWHEEL

LOWER HOOK

BLOCK

LOOSE END RING-

POSITION AS SHOWN

0.91" (23.1 mm)

MAXIMUM

THROAT OPENING

.71" (18mm)

MINIMUM SEAT

FIGURE 4

FIGURE 3

.149" (3.8mm)

STOCK DIAMETER

.496" (12.6mm)

MAXIMUM PITCH

FIGURE 5

4

Series 602/603 Operating, Maintenance & Parts Manual

TO AVOID INJURY:

With a load applied to the hoist, do not force the directional lever into the center (neutral) position.