0 installation, Precaution – Cleveland Motion Controls Classic UPB Transducer Load Cell REV BA User Manual

Page 4

INSTRUCTION NUMBER: AO-70136 BA

4of 9

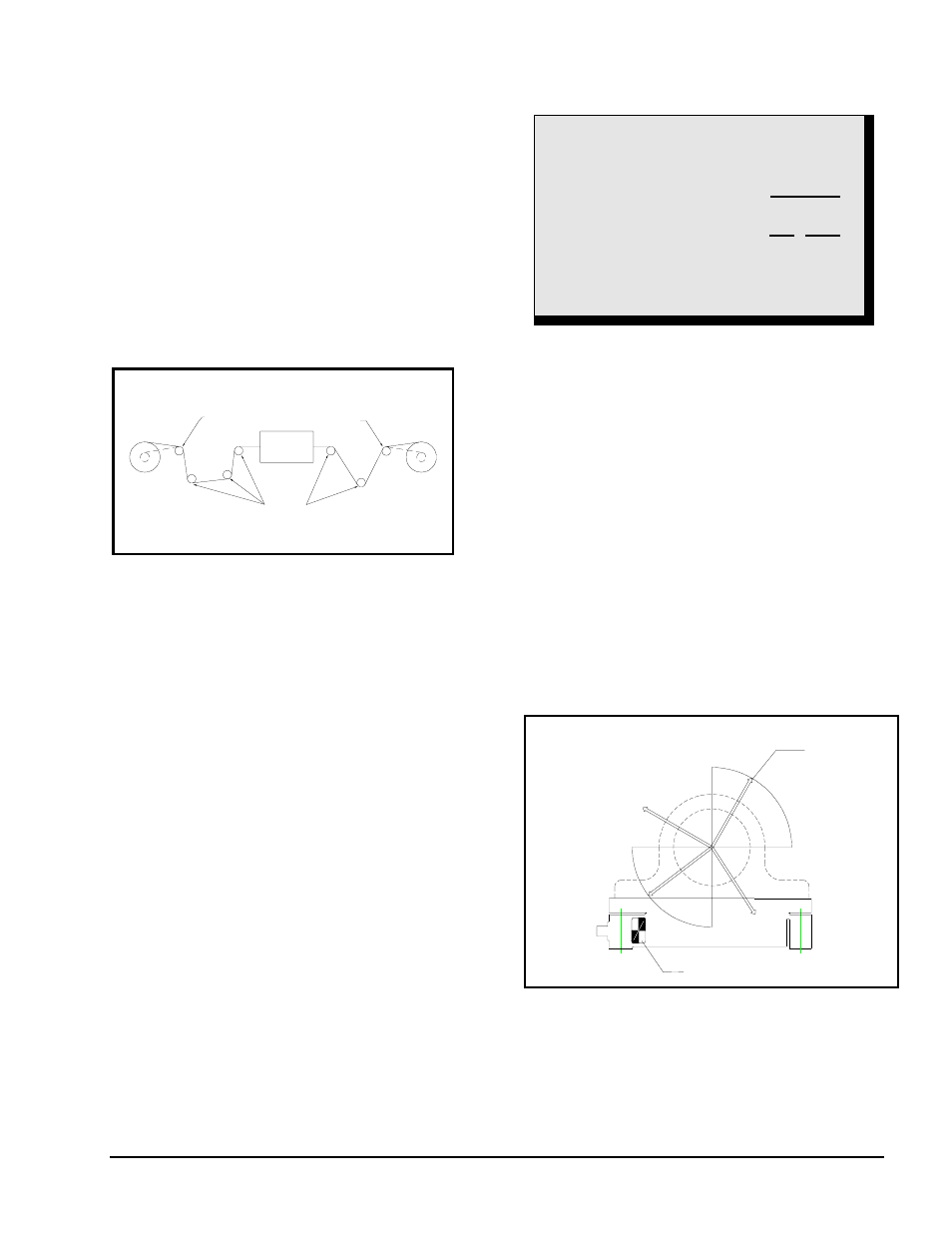

CORRECT

CORRECT

INCORRECT

INCORRECT

WEB FORCE

LOAD ZONE DIRECTION LABEL

2.0 INSTALLATION

2.1 SELECTION OF TRANSDUCER

MOUNTING

LOCATION

When selecting a transducer mounting location,

keep in mind that the tension-sensing roll must

NOT be mounted where the web wrap angle can

vary. Any change in the wrap angle will be sensed

by the transducers as a change in tension, and

indicated as such on the tension indicator.

Figure 3

In some cases, it may be impossible to find a

location for the transducers where the wrap angle

does not vary. The change in indicated tension that

will result can be calculated and, if small, may not

be significant.

2.2 MOUNTING

SURFACE

PREPARATION

The mounting surfaces for the transducers should

be flat and parallel. Prepare the machine frames or

mounting surfaces by removing any loose paint,

rust, scale, etc.

2.3 INSTALLATION

PRECAUTIONS

To insure proper installation and operation of the

system, the following steps should be performed in

sequence. Failure to do so could seriously

damaged the Transducers and void the warranty.

2.4 INSTALLATION OF TYPE

UPB

TRANSDUCERS

Instructions for Mounting the UPB Load Cell to

the Machine Frame (see Figure 6)

Remove the pillow block mounting plate (it is held

in place by four stainless steel corner bolts) in order

to gain access to the four load cell mounting holes.

Drill and tap the machine frame to match the load

cell mounting holes (refer to section 2.5 to properly

position the load cell). Bolt the load cell in place.

The UPB load cell is designed so that either

imperial or metric mounting bolts can be used when

mounting the load cell to the machine frame. Refer

to E in the Figure 2 above for the proper bolt size.

Before remounting the pillow block mounting plate,

refer to section 2.6.

Figure 4

2.5 POSITIONING THE TRANSDUCER

Once the four tapped holes have been drilled, you

need to orient the UPB load cell properly to obtain

PRECAUTION

Always install, orient and firmly bolt

down the transducers BEFORE

installing the tension-sensing roll. When

disassembling or installing, DO NOT

remove the transducer and the tension-

sensing roll as an assembly - remove the

roll first, before loosening the transducer

mounting bolts.

WRAP VARIES

WRAP VARIES

PROCESS

OK FOR TENSION SENSING