7750 series, Installation instructions – KING 7750 Series User Manual

Page 2

(714) 891-0008 • www.kinginstrumentco.com

When it comes to flow...we’re instrumental.

2

7750 Series

Installation Instructions

caution

• Do not loosen nuts that fasten indicator housing to metering tube.

If the relationship of meter tube and indicator housing are changed,

meter must be calibrated.

• Serious property damage and great personal injury could occur as

the result of a meter misused or used in an unsuitable application.

cleaning

Flange Connection: Carefully remove the flowmeter from piping

system. Remove the inlet float stop and outlet float stop and withdraw

float from top of meter. All necessary instrument components are now

fully accessible for cleaning with a bottle brush and appropriate mild

soap solution*. Before the meter is reassembled, inspect all parts for

damage.

To reassemble, carefully guide the magnetic float back into the tube.

Reinstall and tighten inlet float stop and outlet float stop. Reinstall the

instrument into the plumbing system.

FnPt Connection: Carefully remove the flowmeter from piping

system. Remove the inlet float stop and outlet float stop by twisting

and withdrawing from the top. Remove the float from top of meter. All

necessary instrument components are now fully accessible for clean-

ing with a bottle brush and appropriate mild soap solution*. Before

the meter is reassembled, inspect all parts for damage.

To reassemble, carefully guide the magnetic float back into the tube.

Reinstall and tighten inlet float stop and outlet float stop. Reinstall the

instrument into the plumbing system.

*Do not use cleaning agents that will damage float or tube.

Meters should be cleaned with a mild soap solution. This will be an

effective cleaner of rust stains. Caution must be used so that materials

of construction are not damaged by cleaning solutions. Hard water

deposits can be removed with 5% acetic acid solution (vinegar).

repair

7750 meters that require repair should be sent to the factory. Please

call for a Return Merchandise Authorization (RMA) number and return

instructions.

warning:

Pressure and temperature ratings are based on a study of the engi-

neering data for particular materials used in construction and on the

design of individual models. This information is supplemented by

destructive test results. Meters with stainless enclosures must never be

operated without shields securely in place. Meters exposed to difficult

environments such as those created by certain chemicals, excessive

vibration or other stress inducing factors could fail at or below the

suggested maximums. Never operate meters above pressure and

temperature maximums. It is strongly recommended that all meter

installations utilize an appropriate pressure relief valve and/or rupture

disc. The pressure settings and locations of these devices should be

such that meters cannot be over pressurized. Meter failure could

result in damage to equipment and serious personal injury. Always

use suitable safety gear, including OSHA approved eye protection

when working around meters in service. We are happy to pass along

chemical compatibility information that has been published by the

manufacturer’s of raw materials used in our products; however, this

information should not be construed as a recommendation made by

King Instrument Company, Inc. for a specific application.

7750 series inductive slot sensor

All 7750 Series flowmeters may be fitted with one or two inductive slot

sensors. Inductive slot sensors are 2-wire, DC, low current devices and

are designed to be used with a remote barrier / switch isolator capable

of powering the sensor and providing the desired switching option(s).

Barrier / switch isolators are available with 220VAC, 110VAC or 24VDC

supply voltage requirements, contain single pole double throw (SPDT)

relays, and are DIN rail mountable. (Only 24VDC units are actually

powered by the rail.) See barrier / switch isolator specifications for

electrical connections and further details.

inductive slot sensor-electrical speciFications

TYPE:

Inductive

SUPPLY VOLTAGE:

5-25V DC (Switch Isolator)

OUTPUT: NAMUR

OUTPUT LOAD CURRENT: <= 1mA-Float Present

>= 3mA (15mA Max.)-Float Absent

SWITCHING FREQUENCY: 2kHZ

HOUSING RATING:

IP67

WIRING:

2 Conductor, NAMUR

POS=BROWN / NEG=BLUE

TERMINALS: #1=POS / #2=NEG

PEPPERL+FUCHS

UL:

General Purpose

SENSOR APPROVALS

CSA:

General Purpose

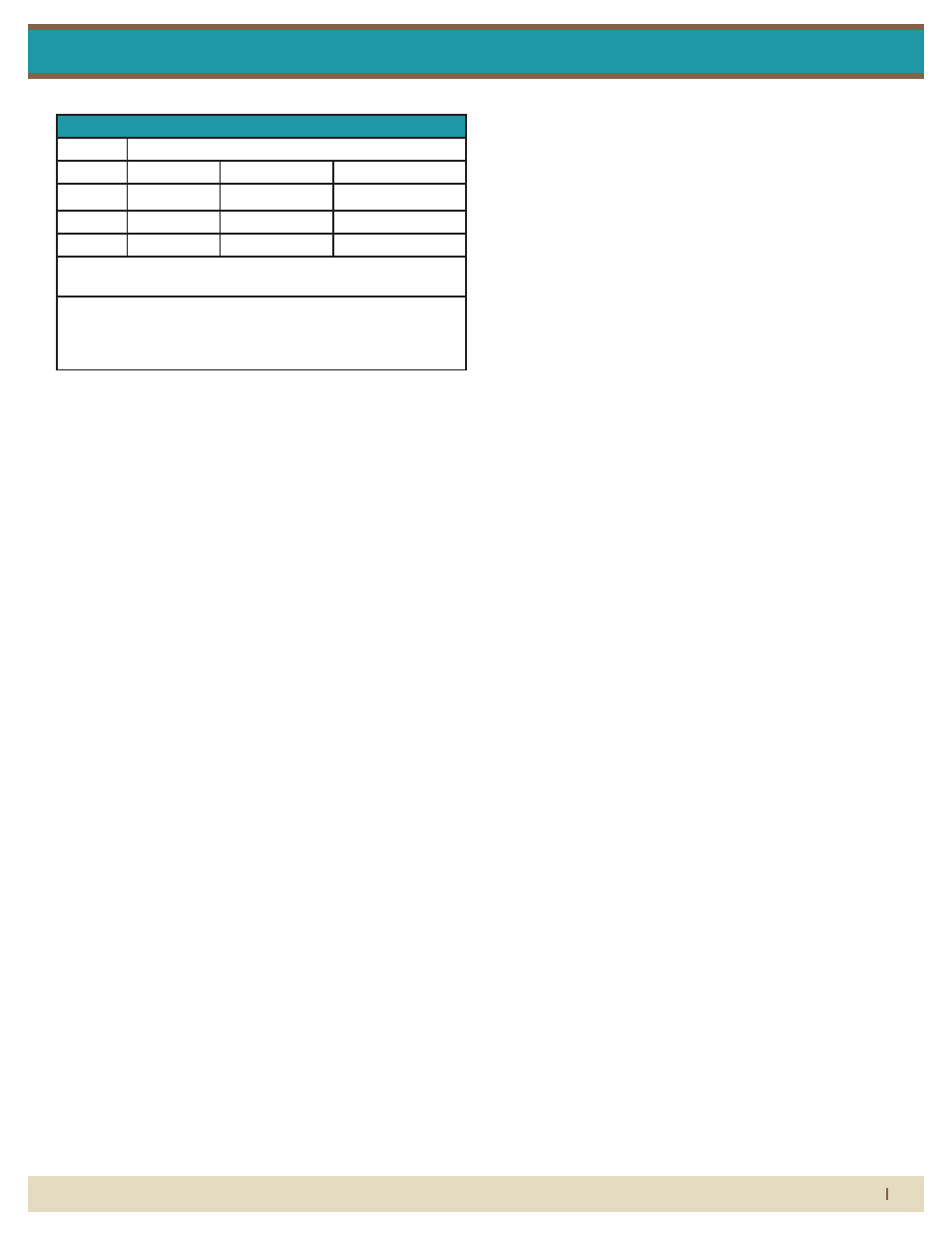

Max non-Shock Pressure and temperature

temp

Stainless Steel Flange Class

°F

150# psig

300# psig

600# psig

200

225

600

1,200

300

200

540

1,100

400

180

515

1,000

Note: The maximum ambient temperature for the indicator housing

is 158°F

**CAUTION: Meters with NPT (threaded) connections can be used in service

up to 1,500 psi and 400° F, but always make certain that materials of

construction (including O-Ring material) are compatible with the fluid to be

metered at the desired temperature and pressure.