3 sensor insertion, 4 sensor removal, 5 mounting accessories – Hach-Lange ORBISPHERE 31xxx Installation and Maintenance User Manual

Page 22: 1 external pressure sensor

20

Installation

4.3 Sensor insertion

•

Insert the sensor straight into the flow chamber or socket.

•

Hand tighten the attaching collar.

•

Connect the sensor cable.

•

Check for leaks; replace O-rings if product leaks are visible.

Micro volume flow chambers:

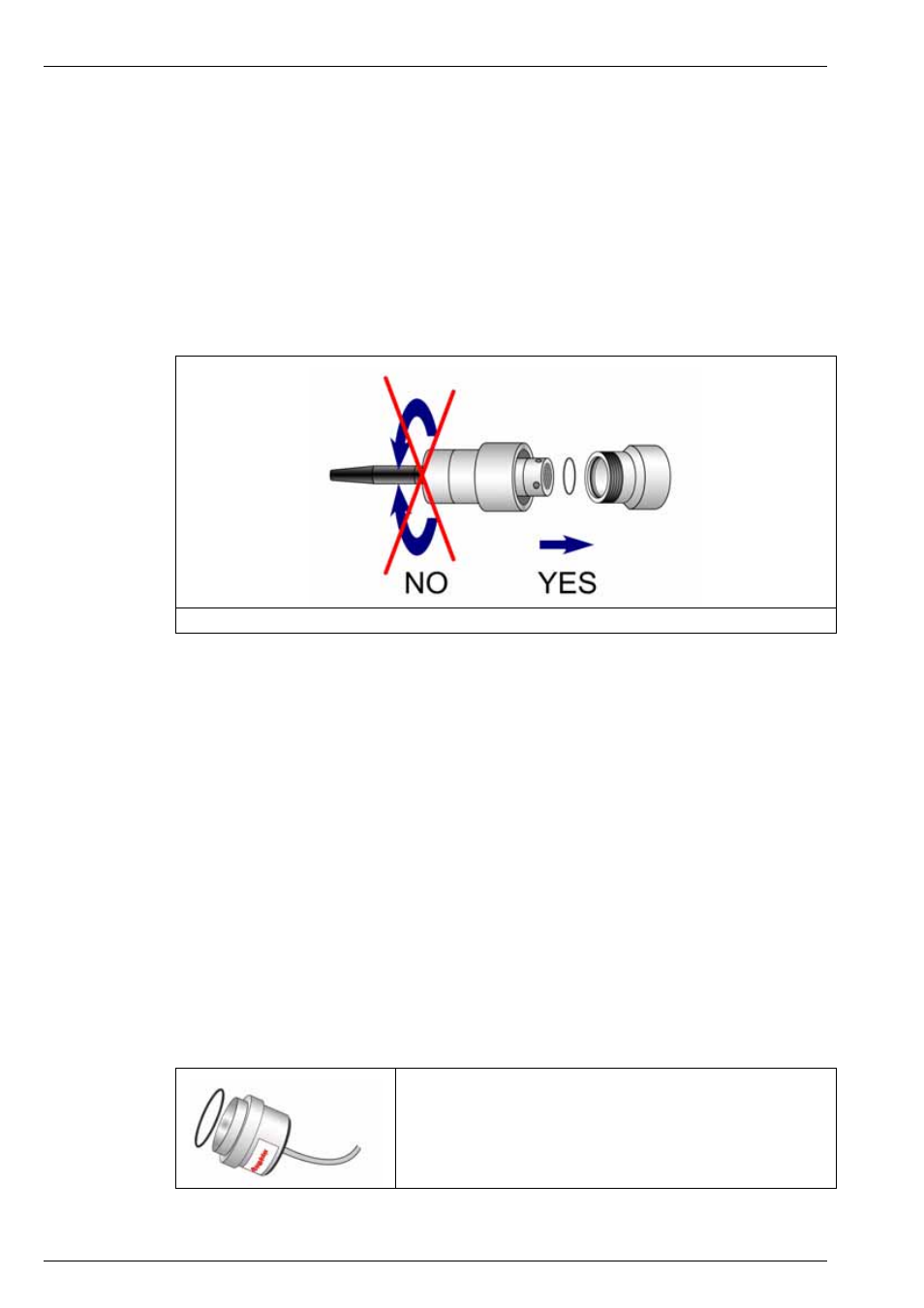

Do not twist the sensor when inserting it into a micro volume flow chamber. This rotation may

twist the membrane holding ring, thus changing the membrane position. This can modify the

membrane measuring conditions, and affect measurement precision.

Note:

Check that the small O-ring at the bottom of the flow chamber is present during removal and

installation of the sensor, as it may stick to the sensor head and fall.

4.4 Sensor removal

•

Shut off the sample flow and drain the sampling circuit of liquid or gas.

•

Remove the sensor cable connected at the sensor end.

•

Hold the sensor body in one hand to avoid rotation and unscrew the collar with the other.

•

Pull the sensor straight out of the socket or flow chamber.

•

Check that both O-rings remain in place inside the flow chambers.

•

Install sensor storage cap and sensor base (to protect the connection).

4.5 Mounting accessories

Note:

Check the spare part list at the end of this manual for ordering information.

4.5.1 External pressure sensor

The system can be fitted with an external pressure sensor. This enables a measurement of

fraction of gas under variable pressure conditions during gas phase measurement.

Figure 6 Sensor insertion

Two models are available, depending on the application:

•

28117 Pressure sensor 0 - 5 bar absolute

•

28117C Pressure sensor 0 - 1 bar absolute