Cashco 5500 User Manual

Page 9

9

IOM-5500

SECTION IX

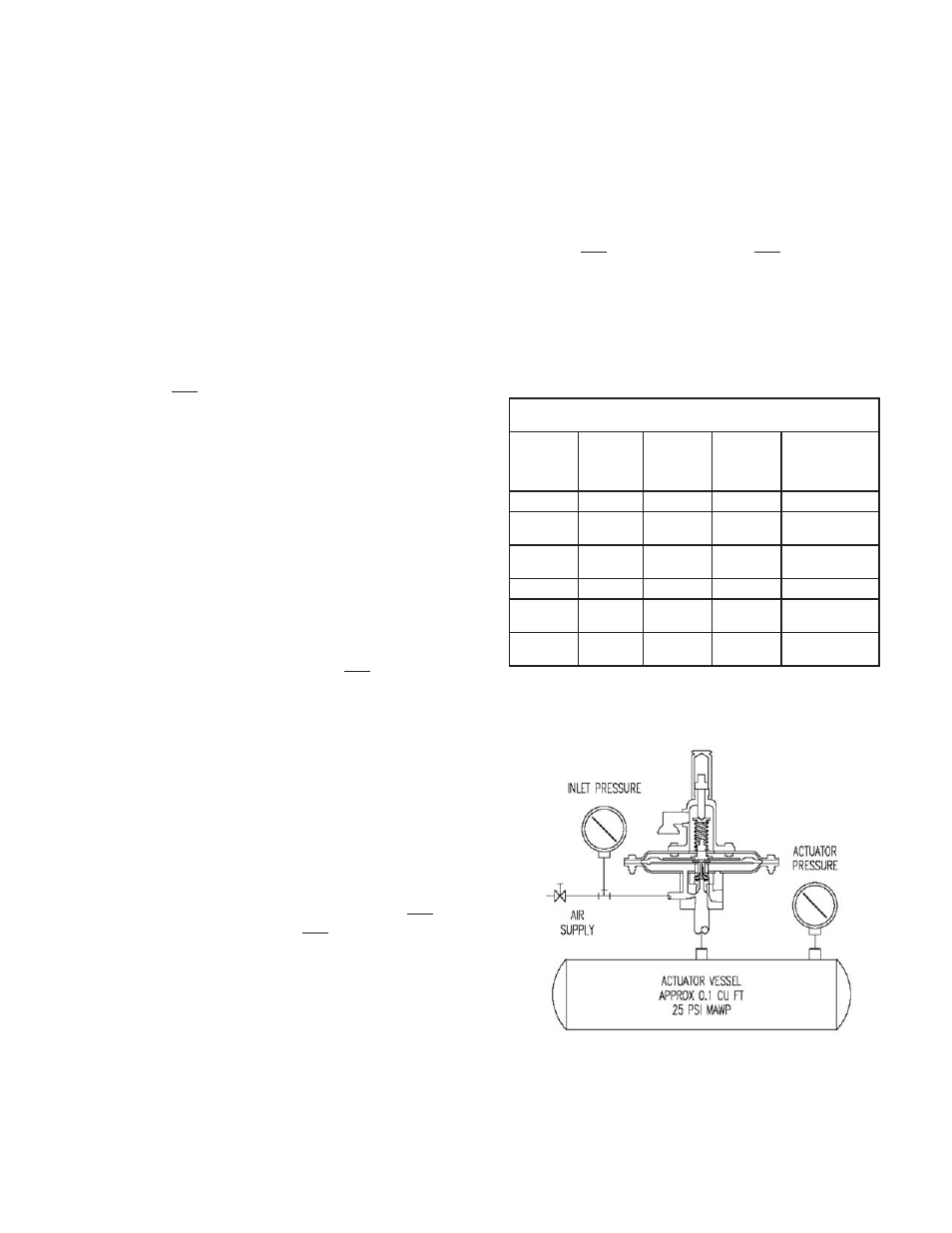

Pilot Valve Test Stand

IX. PRESSURE CALIBRATION AND

TESTING PROCEDURE FOR PILOT:

1. To determine set pressure, slowly increase

the pilot inlet pressure. Simulated actuator

pressure will rise with inlet. As set pressure

is approached, the actuator pressure will be-

gin to decrease. Continue to increase the

inlet pressure slowly until the actuator pres-

sure is 90% (+/- 10%) of the inlet pressure.

This is the set pressure.

4QVCVG VJG UGV RTGUUWTG CFLWUVKPI UETGY

() CW to increase set pressure or CCW

to decrease set pressure. Continue to rotate

VJG CFLWUVKPI UETGY CPF TGRGCV VJG VGUV RGT

5VGR RTGXKQWU WPVKN VJG URGEKſGF UGV RTGU-

sure is achieved.

3. To determine reseat pressure, slowly de-

crease the inlet pressure and the actuator

pressure will begin to increase. Reseat oc-

curs when the actuator pressure equal the

inlet pressure.

4. The difference between set and reseat

RTGUUWTGŒDNQYFQYPŒ ECP DG CFLWUVGF YKVJ

the blowdown needle (). Maximum

clockwise rotation provides rapid relief valve

QRGPKPI őUPCR CEVKQPŒŏ CPF OCZKOWO DNQY-

down. Standard blowdown, unless other-

YKUG URGEKſGF KU

DGNQY UGV RTGUUWTG

5. Increased counter clockwise rotation of

DNQYFQYP UETGY RTQXKFGU őOQFWNCVKPIŒ CE-

tion and minimum (zero) blowdown. Reseat

pressure is the same as set pressure.

NOTE:

6JG DNQYFQYP PGGFNG KU NQECVGF

in a pressure containing chamber, and is

TGVCKPGF D[ VJG DNQYFQYP QTKPI 218) and

DNQYFQYP NQEMPWV 236). DO NOT remove

VJG DNQYFQYP PGGFNG YJKNG WPFGT RTGUUWTG

4GOQXG DQF[ XGPV CPF KPUVCNN C ƀGZKDNG VWDG

in this port. Immerse this pilot discharge

DWDDNG VWDG KP YCVGT CRRTQZKOCVGN[ ΠDG-

low surface to detect cracking and reseat

pressure.

7. A small interaction occurs between set

RTGUUWTG CPF DNQYFQYP CFLWUVOGPVU 4G-

CFLWUVOGPV QH DQVJ OC[ DG TGSWKTGF WPVKN

VJG URGEKſGF UGV RTGUUWTG CPF DNQYFQYP

are achieved. After completion, lock both

screws and locknuts and replace closing cap

( QP CFLWUVKPI UETGY ).

8. Hold the valve at the set pressure while

preforming a soap bubble test of all bolted,

ƀCPIGF CPF VJTGCFGF EQPPGEVKQPU

4GHGT VQ 6CDNG HQT UVCPFCTF UGVVKPI 5RGEKſ-

cations.

TABLE 3

SETTING SPECIFICATIONS - PILOT VALVE

Pilot Action

Set

Pressure

Set

Pressure

Limits

Maximum

Cracking

Pressure %

of Set

Reseat

Pressure

% of Set

Snap

ΠΠ9%

Œ9%

75

90 +/- 3

Snap

Π9%

1.0 psig

+/- 3%

90

90 +/- 3

Snap

1.1 - 15.0

psig

+/- 3%

95

93 +/- 3

Modulating

ΠΠ9%

Π9%

75

100

Modulating

Œ

psig

+/- 3%

90

100

Modulating

1.1 - 15.0

psig

+/- 3%

95

100