Cashco 5500 User Manual

Page 3

3

IOM-5500

SECTION V

V. INSTALLATION:

The Model 5500 POVV is a precision device that

must be handled carefully to ensure seat tightness.

WARNING

6JG XGPV OWUV DG KPUVCNNGF KP C XGTVKECN RQUKVKQP 6JG

tank nozzle on which the vent is mounted should have

VJG UCOG PQOKPCN FKCOGVGT CU VJG XGPVKPI FGXKEG +V

KU TGEQOOGPFGF VJCV VJG VCPM PQ\\NG ƀCPIG HCEG DG

YKVJKP FGITGG QH JQTK\QPVCN HQT DGUV RGTHQTOCPEG QH

VJG XGPVKPI FGXKEG

WARNING

/KPKOWO ENGCTCPEG DGVYGGP VCPM TQQH CPF XCEWWO

KPNGV RQTV OWUV DG CV NGCUV GSWCN VQ VJG XGPVUŏ PQOK-

PCN ƀCPIG DQTG 6CPM PQ\\NG DQTG OWUV DG ITGCVGT

VJCP QT GSWCN VQ XGPV KPNGV ƀCPIG DQTG +PNGV RKRKPI

NQCFU OWUV DG UWRRQTVGF D[ CRRTQRTKCVG UVTWEVWTCN

UWRRQTVU 016 D[ VJG XGPV DQF[

1. At installation, the POVV should be carefully

lifted into position using the lifting lugs on the

DQF[ 7UG VJG ECUG CUUGODN[ VQ JGNR

align the body directly over the tank nozzle.

DO NOT use the pilot valve or pickup line to

pull the POVV into position.

#NWOKPWO DQF[ XGPVU UJQWNF DG OCVGF VQ

ƀCVHCEGF #5/' ƀCPIGU /CVKPI ƀCPIGU

UJQWNF DG ƀCV YKVJKP Œ CPF ENGCP HTGG

of scratches, corrosion and tool marks. A full

faced gasket is recommended.

+PUVCNN VJG ƀCPIG ICUMGV QP VJG PQ\\GN HCEG

Use either a full faced or ring gasket for

TCKUGF HCEG ƀCPIGU 'PUWTG VJCV VJG ICUMGV

material is suitable for the service. See Table

1 for gasket dimensions.

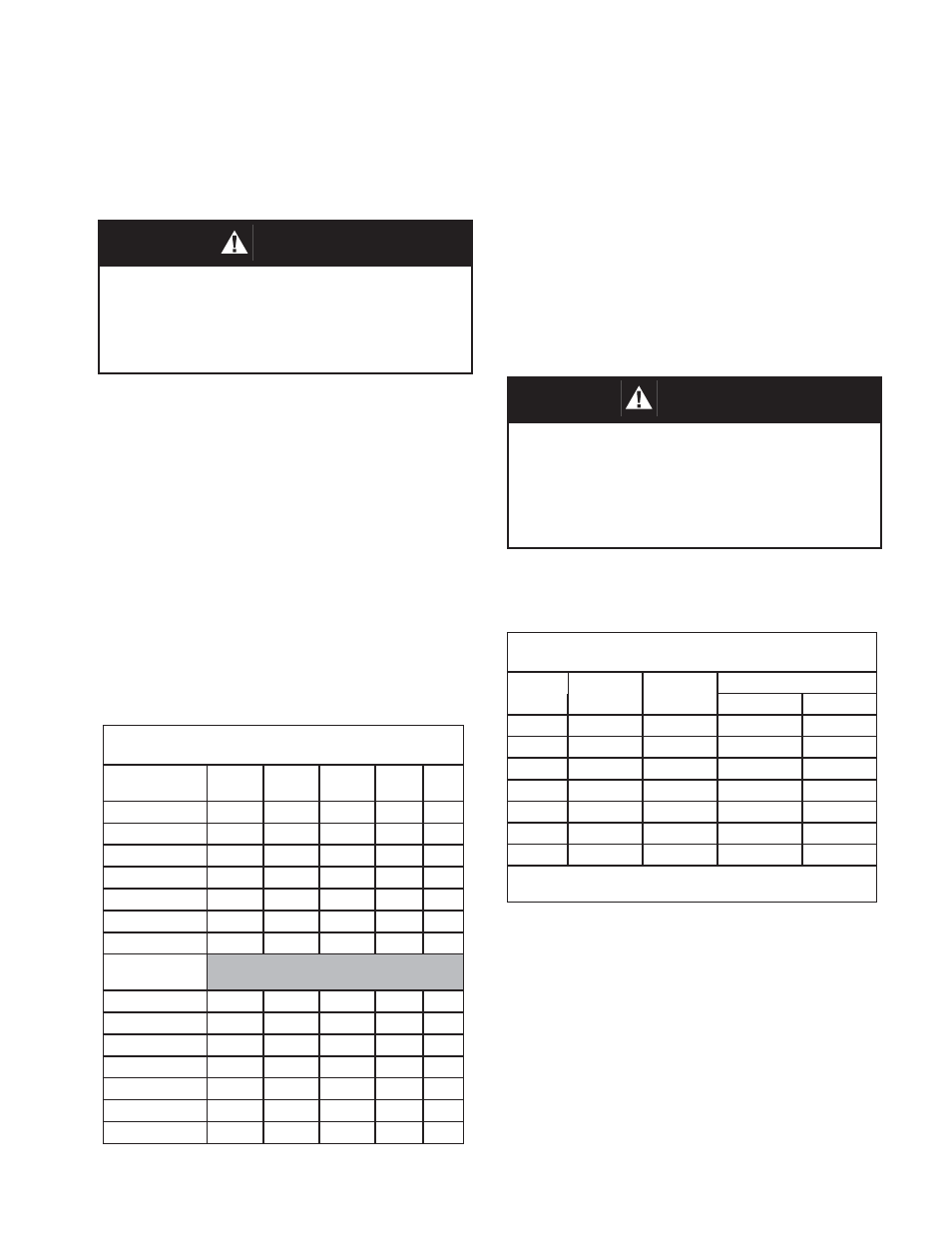

6CDNG

$QF[ (NCPIG )CUMGV &KOGPUKQPU

CS, SST

150# ASME RF

O.D.

I.D.

B.C.

Hole

Qty

ŏ

--

--

--

Œ

5.38

3.50

--

--

--

Œ

6.88

4.50

--

--

--

Œ

8.75

--

--

--

Œ

11.00

--

--

--

Œ

13.38

10.80

--

--

--

Œ

--

--

--

Alum w/ 125#

ASME FF

Œ

6.00

4.75

.75

4

Œ

7.50

3.00

6.00

.75

4

Œ

9.00

4.00

7.50

.75

8

Œ

11.00

6.00

9.50

.88

8

Œ

13.50

8.00

11.75

.88

8

Œ

16.00

10.0

1.00

Œ

19.00

17.00

1.00

4. Center the gasket within the bolt circle of the

VCPM PQ\\NG ƀCPIG

5. Lubricate all studs and nuts with an appropri-

ate thread lubricant. If stainless steel studs

and nuts are required, use an anti-seize lubri-

ECPV UWEJ CU OQN[FKUWNſFG

4GOQXG ƀCPIG RTQVGEVKXG EQXGT CPF ECTGHWNN[

set the POVV down on the gasket

CPF HCEG QH VJG PQ\\NG ƀCPIG

7. Install lockwashers and nuts. Tighten nuts

to half the recommended torque value using

CP CNVGTPCVKPI ETQUUKPI RCVVGTP 5GG 6CDNG

6CDNG

Recommended Minimum Torque Values *

Size

Qty

Holes

Bolt

(UNC)

Torque (lb-ft)

Raised Face

Flat Face

Œ

4

Œ

31

81

Œ

4

Œ

43

106

Œ

8

Œ

68

Œ

8

ŏ

51

101

Œ

8

Œ

78

Œ

Œ

75

138

Œ

Œ

93

179

* Torque vlaues are based on a gasket factor m = 3.5,

gasket factor y = 4000 psi, operating pressure = 30 psi

8. Make sure that the gasket is compressed

GXGPN[ CPF VJG ƀCPIGU CTG PQV FKUVQTVGF

NOTE: /KUCNKIPOGPV QH ƀCPIG HCEGU YKNN ECWUG

DGPFKPI UVTGUUGU CV VJG ƀCPIG CPF OC[ FCOCIG

ƀCPIG LQKPV

9. Finish tightening nuts to the point that no ad-

ditional rotation occurs.