Installation instructions, Figure 2, Figure 1 – Hydrotech 6700 Valve Upflow Automatic Water Softeners Operation Manual User Manual

Page 3

2

Installation Instructions

All government codes and regulations governing the installation of these devices must be observed.

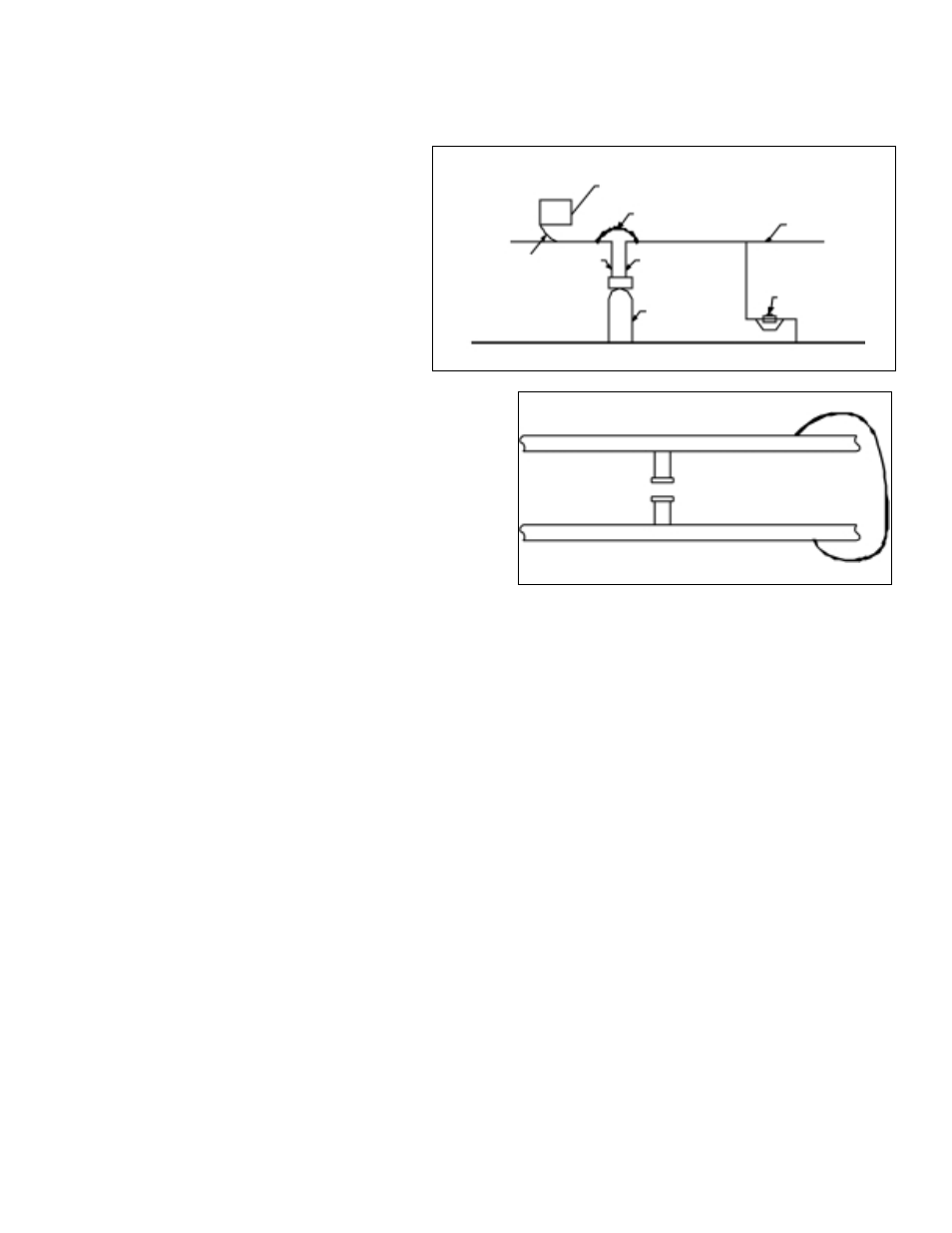

CAUTION: If the ground from the electrical panel or

breaker box to the water meter or underground

copper pipe is tied to the copper water lines and

these lines are cut during installation of the Noryl

bypass valve and/or poly pipe, an approved

grounding strap must be used between the two lines

that have been cut in order to maintain continuity. The

length of the grounding strap will depend upon the

number of units being installed and/or the amount of

copper pipe being replaced with poly. See Figure 1.

In all cases where metal pipe was originally used and

is later interrupted by poly pipe or the Noryl bypass valve as in

Figure 1 or by physical separation as in Figure 2, an approved

ground clamp with no less than #6 copper conductor must be

used for continuity, to maintain proper metallic pipe bonding.

Check your local electrical code for the correct clamp and cable

size.

1. Position the conditioner on a flat surface, near a drain and a

115 volt AC outlet. The unit is provided with a 24V adapter.

2. Study the layout of the present water lines and drains in order that you can determine the best location for your water

conditioner and plan your installation. Your conditioner must not be subjected to freezing or to water temperatures

above 110°F which will void the warranty.

3. All plumbing should be done in accordance with local plumbing codes. The pipe size for the drain line should be a

minimum of 1/2”. However, a 3/4” drain line is required where backwash flow rates are in excess of 7 gpm or the

length of the drain line is greater than 20 feet.

4. Soldering joints near the drain must be done prior to connecting the drain line flow control (DLFC). Leave at least 6”

between the DLFC and the solder joints when soldering pipes that are connected on the DLFC. Failure to do this

could cause interior damage to the DLFC.

5. Teflon tape is the only sealant to be used on the drain fitting.

6. Make sure that the floor is clean and level beneath the salt storage tank.

7. Place approximately 1” of water above the grid plate. If a grid is not utilized, fill to the top of the air check in the salt

tank. Do not add salt to the brine tank at this time.

8. On units with a bypass, place in BYPASS position. Turn on the main water supply. Open a cold soft water tap nearby

and let run a few minutes or until the system is free from foreign material (usually solder) that may have resulted from

the installation. Once clean, close the water tap.

9. Place the bypass in the SERVICE position and let water flow into the mineral tank. When water flow stops, slowly

open a cold water tap nearby and let run until the air the air is purged from the unit.

10. Plug unit into an electrical outlet. NOTE: all electrical connections must be connected according to local codes.

Figure 2

Outside Water Line For Outside

& 3rd Tap Comes From Meter

Filtered Water Line in Home

Unfiltered Water Bypass

Loop Cut & Capped

Ground Strap Required

Because of Break in Continuity

Figure 1

Electrical Panel

Ground Strap

Poly Pipe

Ground

From

Panel

Poly Pipe

Softener

c/w Plastic Bypass

Copper Pipe

Water Meter