How your 9100sxt downflow water conditioner works, Performance data sheet and specification, Control operation during regeneration – Hydrotech 9100 SXT Valve Meter Initiated Water Softener User Manual

Page 3

1

How Your 9100SXT Downflow Water Conditioner Works

Hard water enters your home through the main supply line, enters the softener and passes down through a resin mineral

bed which softens the water. An ion exchange process takes place in which the resin beads capture and hold calcium and

magnesium, the hardness minerals, while the water takes on sodium ions. The soft water then flows into your household

water line.

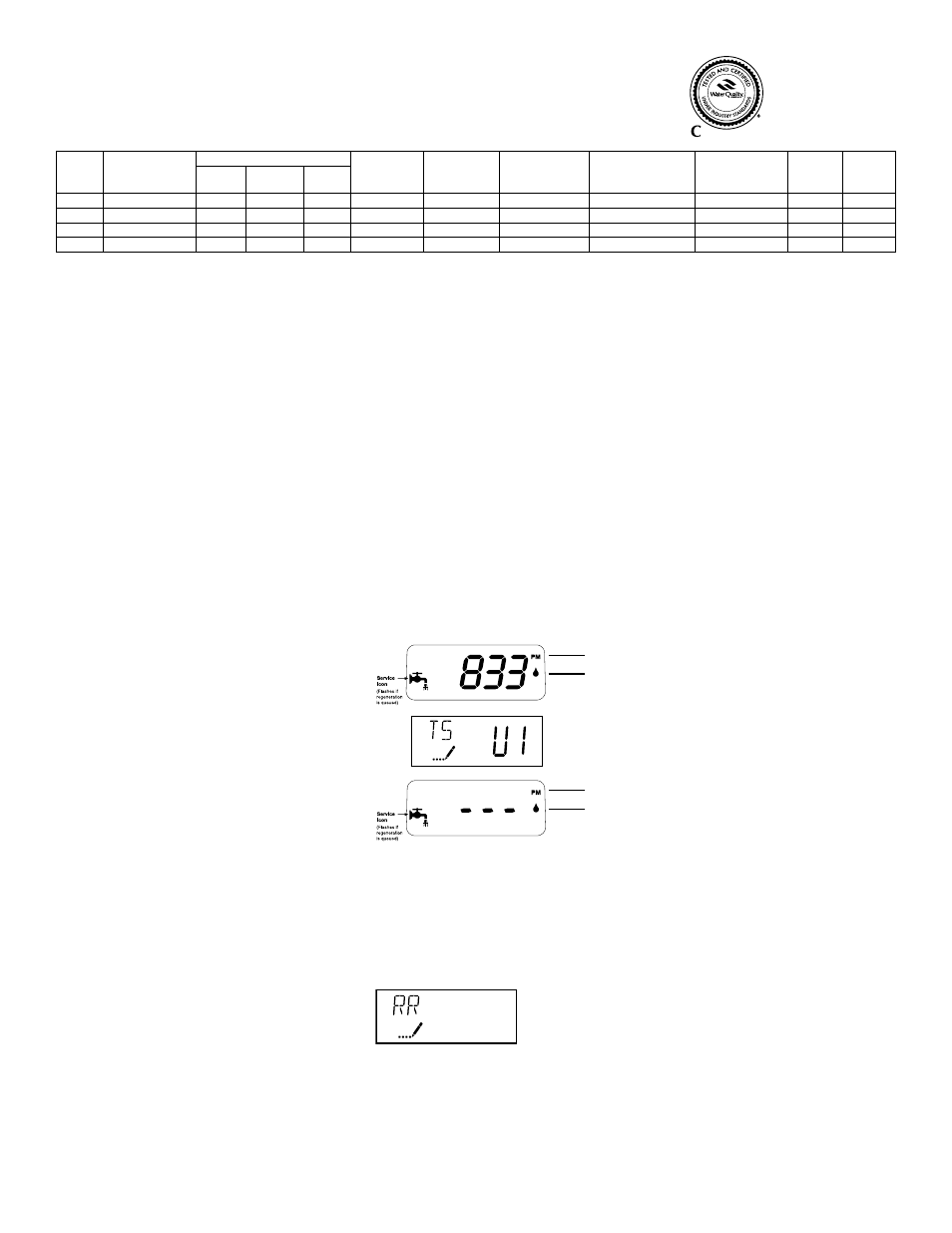

In normal operation, the Time of Day display will alternate being viewed with the Volume Remaining display then the Tank

in Service. This display will be in gallons, liters or cubic meters. The tank in service will be shown as U-I or U-2. As treated

water is used, the Volume Remaining display will count down from a maximum value to zero or (---).Once this occurs, a

regeneration cycle will be initiated at the Set Regeneration Time. Water flow through the valve is indicated by the Flow

Indicator that will flash in direct relationship to flow rate.

Example

833 Gallons of Treated

Water Remaining

Tank In Service

0 Gallons of Treated

Water Remaining

Control Operation During Regeneration

In regeneration, the control will display a special regeneration display. In this display, the control will show the current

regeneration step number the valve is advancing to or has reached and the time remaining in that step. The step number

displayed will flash until the valve has completed driving into this regeneration step position. Once all regeneration steps

have been completed, the valve will return to Service and resume normal operation.

Example

Less than 6 minutes

remaining in Regen

Step Rapid Rinse

Pushing the Extra Cycle Button during a regeneration cycle will immediately advance the valve to the next cycle step

position and resume normal step timing.

5

PM Indicator

Flow Indicator

(Flashing with water flow)

PM Indicator

Flow Indicator

(Flashing with water flow)

WQA Tested and

Certified against

CSA B483.1

Performance Data Sheet and Specification

Item

Number

Model

Number

Capacity - Grains

Service

Flow Rate

USGPM (LPM)

Maximum

Flow To Drain

USGPM (LPM)

Resin

Tank Size W x H

inches (mm)

Brine Tank Size

W x H

inches (mm)

Resin

Volume per tank

cu. ft (litres)

Salt

Capacity

lbs (kg)

Shipping

Weight

lbs (kg)

@ 15 lbs

/cu.ft

Factory @

10 lbs/cu.ft

@ 6 lbs

/cu.ft

7634

9100SXT-20 TMI

22,000

20,000

15,000

8 (30)

1.5 (5.7)

0.75 (21)

8 x 44 (203 x 1117)

21 x 36 (533 x 914)

308 (140)

170 (77)

7627

9100SXT-30 TMI

30,000

27,000

20,000

10 (37.9)

1.5 (5.7)

1.00 (28)

9 x 48 (229 x 1219)

21 x 36 (533 x 914)

308 (140)

185 (84)

7628

9100SXT-45 TMI

45,000

41,000

30,000

11 (41.6)

2.0 (7.6)

1.50 (43)

10 x 54 (254 x 1372)

21 x 36 (533 x 914)

308 (140)

248 (113)

7629

9100SXT-60 TMI

60,000

55,000

40,000

15 (56.8)

3.0 (11.4)

2.00 (57)

12 x 52 (305 x 1321)

21 x 36 (533 x 914)

308 (140)

340 (154)

Working Temperature = 34-110°F (1-43°C)

(Do not subject the unit to freezing temperatures)

Working Pressure = 20-125 PSIG (137-861 kPa)

Voltage = 120V / 60 Hz

• Capacities are based on two tanks of resin. Eg: 9100SXT-30 set at 10lb/cf salt setting would provide 27,000 grains of

hardness removal for one tank.

• Peak flow rates are intended for intermittent use only and are for residential application only.

• The manufacturer reserves the right to make product improvements which may deviate from the specifications and

descriptions stated herein, without obligation to change previously manufactured products or to note the change.

• Do not use water that is microbiologically unsafe without adequate disinfection before or after the system.