Troubleshooting, Maintenance schedule, Valve replacement - troubleshooting – Hydra-Flex Aqua-Lab SD Operating Manual User Manual

Page 9

Operating Manual

© Hydra-Flex Inc 2011

- 6 -

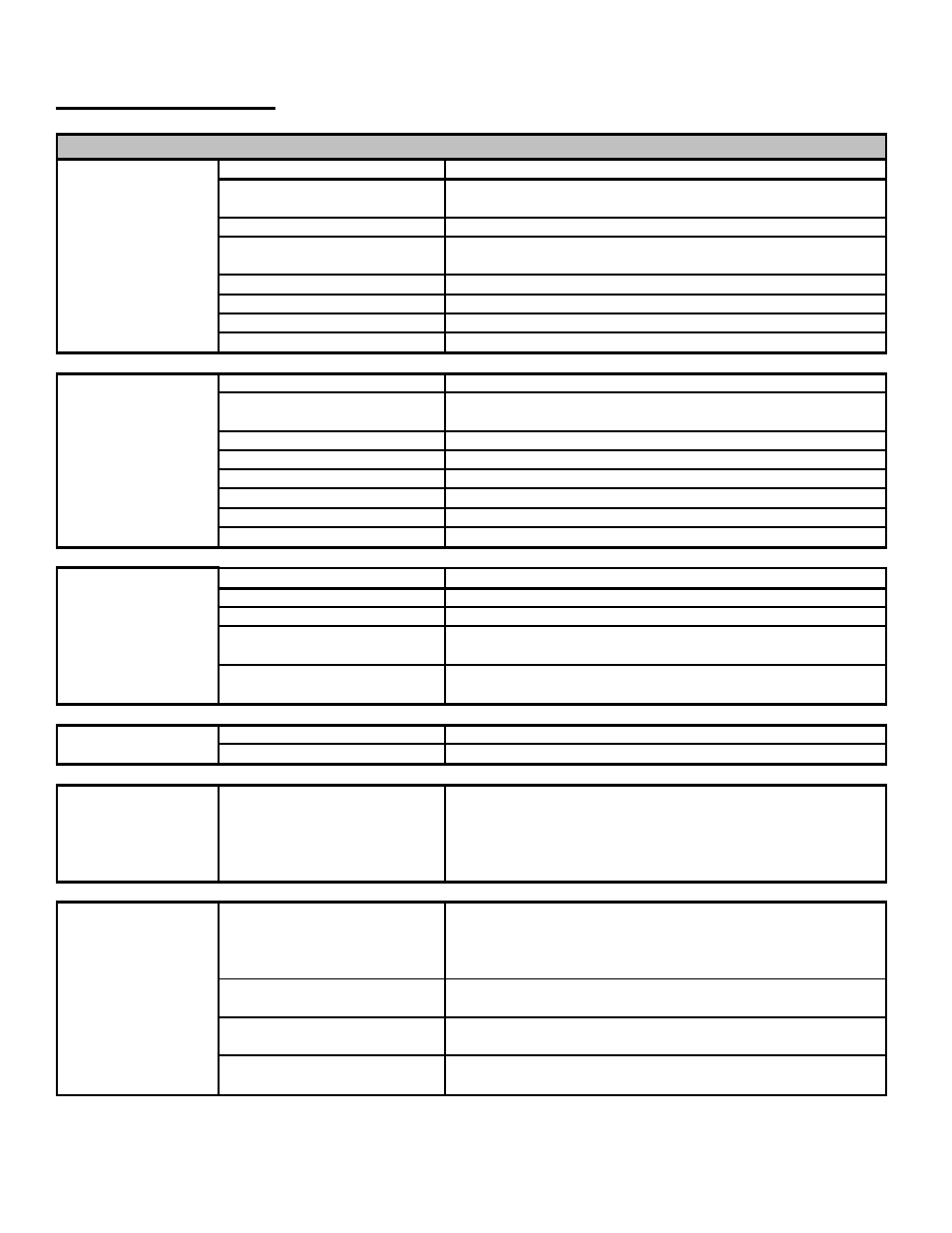

Troubleshooting

PROBLEM

POTENTIAL CAUSES

SOLUTIONS

Pump not primed

See priming instructions

Inlet Restriction

Check all in-line filters and inlet plumbing for restrictions. Check

valves and backflow preventers

Missing 1 of 3 Phases

Wire according to diagram

Inadequate water supply

Check pressure on inlet side of pump to be sure positive

pressure is maintained

Undersized piping

Replace with larger piping

Leak on the Inlet side

Make sure connections are tight

Worn or defective pump parts

Replace worn parts or entire pump, Clean parts if required

Incorrect Motor rotation

Reverse motor rotation by interchanging any two leads

Blown fuse or circuit breaker

Replaced fuses or close circuit breaker

Defective Motor Starter

contactor

Replaced motor starter contactor

Current Sensor set to high

Verify wiring

Thermal Overload set to low

Adjust setting on thermal overload to match voltage

Incorrect Motor Voltage

Voltage must be within 10% of motor rated voltage

Defective motor

Replace motor

E-Stop is depressed

unlock E-Stop

Pump components damaged

Replace worn part or entire pump

Not Primed

Reprime pump

Pump not secured firmly

Secure properly

Restricted Inlet

Clean or correct restriction

Water regulator fluttering

Try to adjust regulator down and then back up or replace

regulator

Cavitation (Sounds like marbles

in pump)

Increase inlet size

Worn mechanical seal

Replace shaft seal

Worn o-ring seals

Replace

Injector is not

drawing chemical -

Passes Vacuum

Pressure check

test

Clogged chemical feed

Check chemical hose, foot valve, metering tip and hose barb

for debris or clogs

Too much back pressure on

injector

Perform back pressure check test outlined in Section IV if this

manual. If the result is higher than 66 psi then Increase arch

nozzle size or quantity, use larger tubing, or use a smaller flow

injector

Clogged injector check valve

Blow compressed air through the chemical hose barb on the

injector to remove debris

Clogged injector nozzle

Remove injector and blow out any debris with compressed air

Defective Injector

If Vacuum check fails but Back Pressure is less than 66 psi,

replace the injector

Pump won't start or

run at full speed

Pump Operates, but

delivers little or no

water

Injector is not

drawing chemical -

Fails Vacuum

Pressure check

test

Pump Leaks

Excessive Noise from

Pump