Operating manual – Hydra-Flex Aqua-Lab SD Operating Manual User Manual

Page 10

Operating Manual

© Hydra-Flex Inc 2011

- 7 -

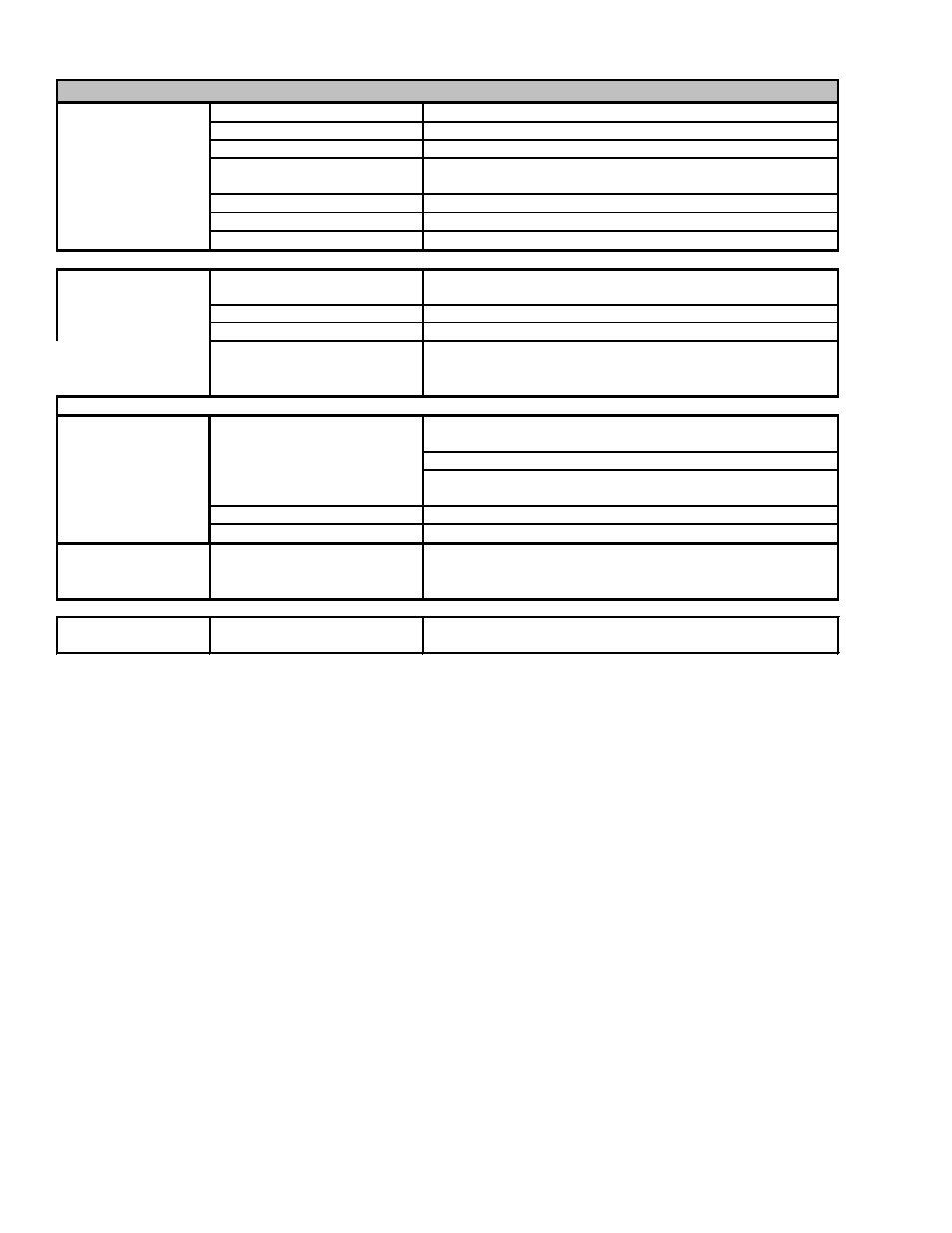

PROBLEM

POTENTIAL CAUSES

SOLUTIONS

Pump not primed

Follow priming instructions

Debris in regulator

Remove regulator and clean out debris

Motor rotation incorrect

Verify rotation and adjust wiring to correct

Opening to many valves at once System is limited to opening up to 8 valves at once or pressure

will be greatly affected by so much demand

Defective Check Valve

Replace check valve if broken

Defective Regulator

Replace Regulator

Defective Pump

Replace Pump

Incorrect Injector Flow Rate

Selection

Replace with desired injector size

System pressure too low

Ensure system pressure is set at 200 psi

Foam Generator Plugged

Ensure cleaned and clear

Downstream pluming restrictive Perform Back pressure test outlined in Section IV of this

manual, if over 66 psi, increase tube size and reduce elbows,

turns or other restrictive plumbing

Solenoid valve malfunction

Ensure valve is receiving the correct electrical signal and

voltage

Valve may be assembled incorrectly

Disassemble valve and clean out debris (See valve

replacement instructions)

Clogged Injector

Remove injector and blow out debris with compressed air

No water supply

Check that the system has a supply of water

Valve stuck open –

Staying open when

signal is off

Debris in valve seat

Remove and clean valve (See valve replacement instructions)

Starter Tripping

Incorrect Overload Setting

Verify overload setting versus settings found in specs page of

this document

Flow at arch is too

low

System won't

regulate up to 200

psi

No flow from injector