Assembly of switch pak, Safety precautions – Flowline AX18 Switch-Pro User Manual

Page 4

Step Four

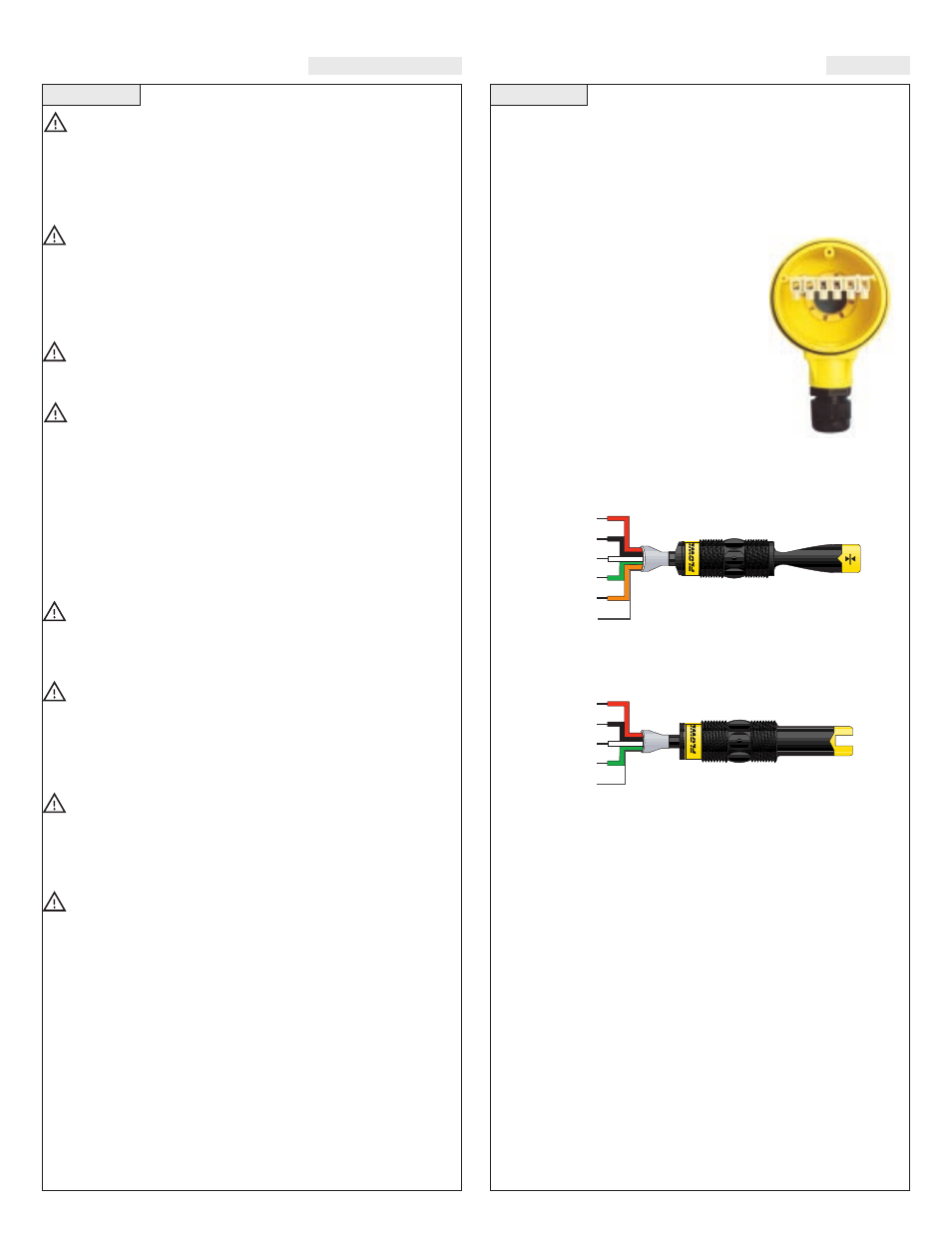

ASSEMBLY OF SWITCH PAK™

Step Three

SAFETY PRECAUTIONS

About this Manual:

PLEASE READ THE ENTIRE MAN-

UAL PRIOR TO INSTALLING OR USING THIS PRODUCT.

This manual includes information on the Switch Pro™ with

Compact Junction Box: AU15-_13_ and AZ18-113_. The units

are identical except for the material of construction and the

sensors technology.

User's Responsibility for Safety:

Flowline manufactures

a wide range of liquid level sensors, controllers, and mounting sys-

tems. It is the user's responsibility to select components that are

appropriate for the application, install them properly, perform tests

of the installed system, and maintain all components. The failure to

do so could result in property damage or serious injury.

Proper Installation and Handling:

Use a proper sealant

with all installations. Never overtighten the components. Always

check for leaks prior to system start-up.

Material Compatibility:

Polypropylene (PP, a polyolefin): Sensor, Junction Box.

Perfluoroalkoxy (PFA, Teflon®): Sensor (AU15-213_ only).

Ryton (glass filled): Vibration Sensor Only.

Make sure that the application liquids are compatible with the

materials that will be wetted. To determine the chemical compati-

bility between the components and its application liquids, refer to

the Compass Corrosion Guide, available from Compass

Publications (phone 858-589-9636).

Temperature and Pressure:

Switch Pro™ is designed for

use in application temperatures up to 90° C (194° F). The Vibration

and Ultrasonic packages are designed for pressurized applications

up to 150 psi (10 bar).

Wiring and Electrical:

Electrical wiring of any liquid level

control system should be performed in accordance with all applic-

able national, state, and local codes. Take care not to cut or break

the outer insulation jacket of wiring that may be immersed while

routing cables in the Switch Pro™ system. Such breaks of the liq-

uid seal of the sensor system may lead to component failure.

Flammable, Explosive and Hazardous Applications:

Switch Pro™ may be used within flammable or explosive applica-

tions only if the associated components are rated intrinsically safe

for such use. In hazardous applications, use redundant measurement

and control points, each having a different sensing technology.

Make a Fail-Safe System:

Design a fail-safe system that

accommodates the possibility of system or power failure. In criti-

cal applications, Flowline recommends the use of redundant back-

up systems and alarms in addition to the primary system.

About Switch Pro™:

Flowline’s Switch Pro™ with Compact

Junction Box Assembly is an single-point mounting system for

installing one level sensor horizontally within a tank. The compact

junction box features termination for the various wires from each level

switch as well as a 1/2” conduit connection. Switch Pro™ mounts hor-

izontally through a standard 3/4" NPT fitting.

Level Switches:

Switch Pro™ includes

a single level switch used to identify it’s own

unique wet / dry condition. The technologies

used to indicate level are either Ultrasonic or

Vibration. Each technology features a unique

wiring/power configuration (Ultrasonic and

Vibration technologies require 12 to 36 VDC

power for operation, see below). The switch

is terminated in the Compact Junction Box.

The Compact Junction Box provides a 1/2”

Conduit connection and 6 poles for wire ter-

mination.

Vibration (LZ12-1405 or LZ12-1425)

Wire Configuration:

RELAY

Red

Black

White

Green

Orange

(+)

(-)

N/A

N/A

N/A

Shld

RELAY

(+)

(-)

N/A

N/A

Shld

Red

Black

White

Green

Ultrasonic (LU10-_405 or LU10-_425) Wire

Configuration:

Compact

Junction Box

(inside shown)