Mechanical installation instructions, Pump characteristics, Operating instructions – Fill-Rite FR1616 Series Pump User Manual

Page 2: Troubleshooting

2

MECHANICAL INSTALLATION INSTRUCTIONS

DO NOT install additional foot valves or check valves unless they

have a pressure relief valve set at 50 psi or less.

Use oil resistant pipe sealant or PTFE tape on all pipe threads.

Model FR1612

1.

Select inlet and outlet hoses or pipes compatible with diesel that

can withstand at least 50psi. Ports are 3/4” NPT. Tighten fittings

securely to a liquid tight seal.

2.

Install the strainer provided at the inlet to the suction hose to

prevent debris from being drawn into the pump.

3.

Use a nozzle or valve at the end of the discharge hose that can be

shut off tightly to prevent accidental siphoning when the pump is not

in use.

Model FR1614

1.

Install components as shown in Figure 2. Note the direction of flow

cast into the front of the pump to determine inlet and outlet.

2.

If it is difficult to press the hoses over the barbs, soften the hose by

soaking it in hot water for 20 seconds, then slip it over the barbs.

3.

Tighten hose clamps securely to provide a liquid tight seal.

Model FR1616

1.

Install components as shown in Figure 3. Note the direction of flow

cast into the front of the pump to determine inlet and outlet.

2.

If it is difficult to press the hoses over the barbs, soften the hose by

soaking it in hot water for 20 seconds, then slip it over the barbs.

3.

Tighten hose clamps securely to provide a liquid tight seal. Tighten

the suction tube into the pump (use PTFE sealant tape).

4.

Extend the poly suction tube to a length that will place it a minimum

of 3” from the bottom of the tank or barrel.

5.

Thread the poly bung into the opening and tighten securely.

ELECTRICAL INSTALLATION FOR ALL MODELS

Connect the battery clips provided to a suitable 12 Volt DC supply

capable of delivering the necessary current and voltage.

The red clip is attached to the positive (+) battery terminal.

Black clip is attached to the negative (-) battery terminal or the

vehicle frame.

DO NOT employ a patch cord to extend the cables. If the cable

provided is not long enough, have it replaced by an authorized

electrician.

The pump may be powered by a battery charger of suitable voltage.

To prevent possible fire from sparks, never connect the terminals

from the battery charger to the pump directly. Always connect the

battery clips from the pump to the terminals on the charger.

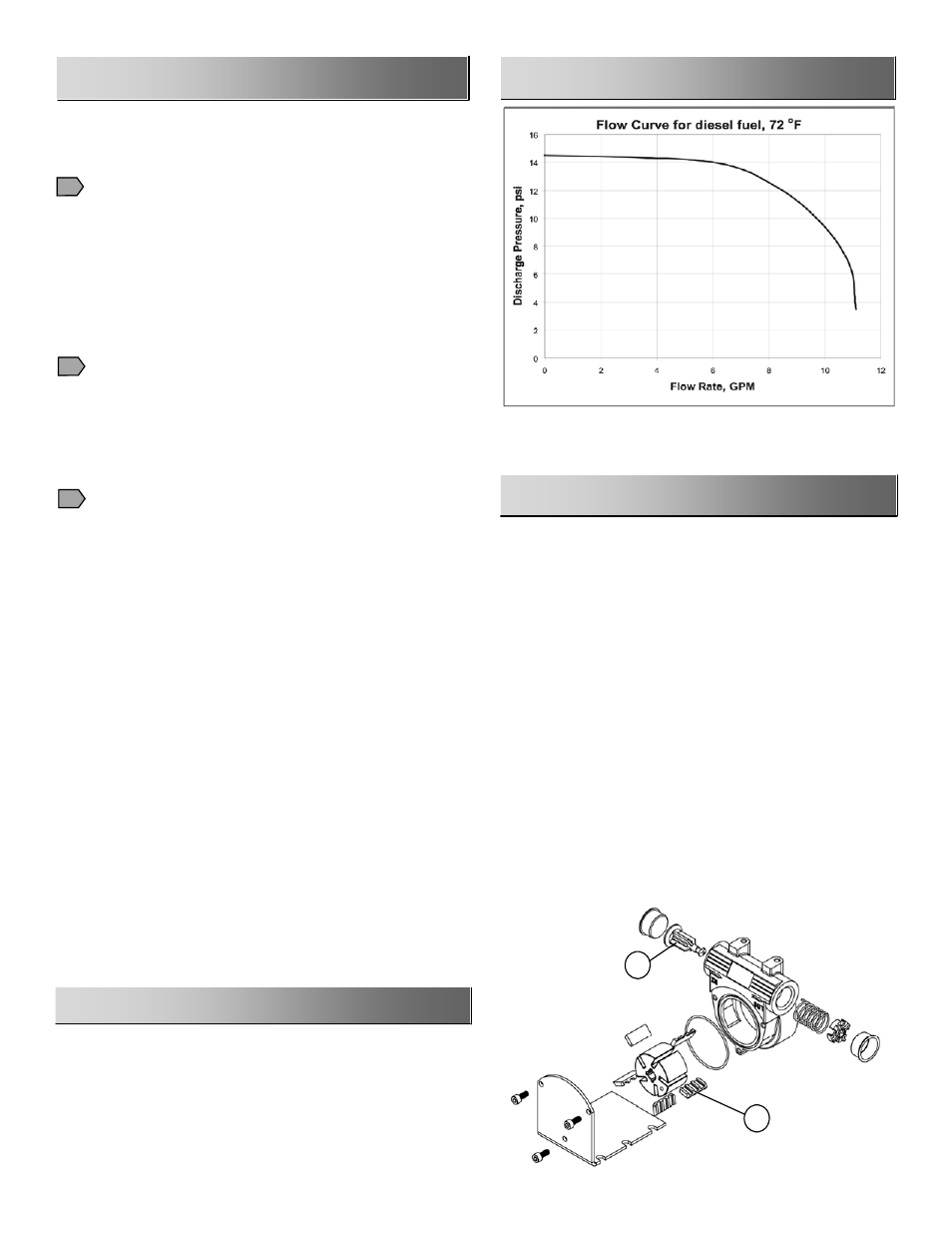

PUMP CHARACTERISTICS

The above flow curve is a guide for pump performance only.

Attachment of accessories, changes in fluid pumped, and

temperature will affect flow rate delivered.

OPERATING INSTRUCTIONS

1.

Insert nozzle into container to be filled.

2.

Switch pump on.

3.

Operate nozzle lever to dispense fluid.

4.

When the desired amount of fluid has been dispensed, release

nozzle lever, remove nozzle form container, and switch pump off.

5.

Nozzle should be kept clean and dry, and securely stored when not

in use.

TROUBLESHOOTING

IF PUMP FAILS TO PRIME:

Check suction line for leaks or obstructions.

Check bypass valve for dirt. The valve should slide freely.

Check electrical connections; the pump will run backwards if the

red and black wires are reversed.

Open nozzle to allow air to be removed from the system.

PUMP IS BOUND:

If the motor hums but the pump does not start, the possible cause is

a stuck rotor. Remove rotor cover and check rotor and vanes for

dirt.

LOW PUMPING CAPACITY:

Strainer screen clogged (strainer screen is in top of poly suction

tube).

Bypass valve not seating properly (1).

Obstruction in suction line.

Make sure all five vanes slide easily in their slots (2).

1

2