Caution – AAON SB-018 User Manual

Page 22

22

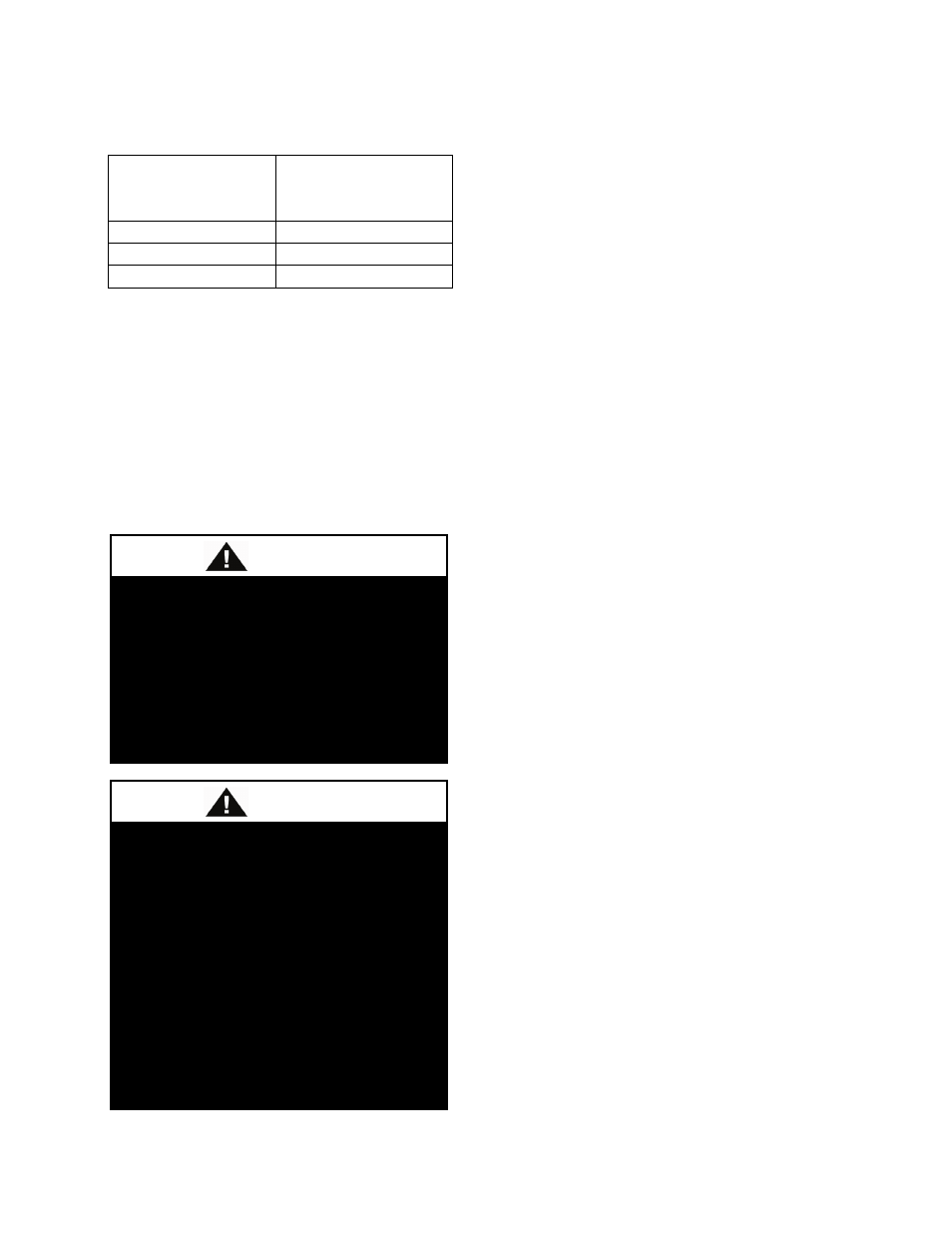

Table 3 - Condenser Water Connections

Model (SB-)

Supply and Return

Connection Size

(in. FPT)

003, 004, 005

1

006, 007, 009, 010

1 1/4

014, 016, 018

1 1/2

Condenser water pump must be field sized

and installed between the cooling tower or

geothermal wellfield and self contained unit.

System should be sized in accordance with

the ASHRAE Handbook. Use engineering

guidelines to maintain equal distances for

supply and return piping and limit bend

radiuses to maintain balance in the system.

Balancing valves, permanent thermometers

and gauges may be required.

Before connection to the unit, the condenser

water system should be flushed to remove

foreign material that could cause condenser

fouling. Install a screen strainer with a

minimum of 20 Mesh ahead of the

condenser inlet to prevent condenser fouling

and internal tube damage. Mineral content

of the condenser water must be controlled.

All make-up water has minerals in it and as

the water is evaporated in the cooling tower,

these minerals remain. As the mineral

content of the water increases, the

conductivity of the water increases.

Field provided and installed water treatment

program must be compatible with stainless

steel, copper, aluminum, ABS plastic, and

PVC. Batch feed processes should never be

used as concentrated chemicals can cause

corrosion. Never use hydrochloric acid

(muriatic acid) or chlorine as it will corrode

stainless steel.

Water loop piping runs through unheated

areas or outside the building should be

insulated.

NOTE: Ball valves should be installed in

the condenser water supply and return lines

for unit isolation and water flow balancing.

All manual flow valves should be of the ball

valve design. Globe or gate valves should

not be used due to high pressure drops and

poor throttling characteristics.

Pressure and temperature ports are

recommended in condenser water supply

and return lines for system balancing. These

openings should be 5 to 10 pipe diameters

from the unit water connections. To allow

for mixing and temperature stabilization,

wells in the water piping should extend at

least ½ pipe diameter into the pipe.

WATER PIPING

Follow national and local codes when

installing water piping. Connections

to the unit should incorporate

vibration eliminators to reduce noise

and vibration and shutoff valves to

facilitate servicing. Supply and return

water piping must be at least as large

as the unit connections and larger

depending on length of runs, rise and

bends.

CAUTION

Installing contractor is responsible for

properly sizing and installing water

system components. Improper fluid

flow due to valves, piping, or

improper pump operation may result

in unacceptable unit operation and

void warranty.

CAUTION