Receiving unit, Storage, Direct expansion (dx) systems – AAON SB-018 User Manual

Page 16: Warning

16

Receiving Unit

When received, the unit should be checked

for damage that might have occurred in

transit. If damage is found it should be noted

on the carrier’s Freight Bill. A request for

inspection by carrier’s agent should be made

in writing at once.

Nameplate should be checked to ensure the

correct model sizes and voltages have been

received to match the job requirements.

If repairs must be made to damaged goods,

then the factory should be notified before

any repair action is taken in order to protect

the warranty. Certain equipment alteration,

repair, and manipulation of equipment

without the manufacturer’s consent may

void the product warranty. Contact the

AAON Warranty Department for assistance

with handling damaged goods, repairs, and

freight claims: (903) 236-4403.

Note: Upon receipt check shipment for

items that ship loose such as filters and

remote sensors. Consult order and shipment

documentation to identify potential loose-

shipped items. Loose-shipped items may

have been placed inside unit cabinet for

security. Installers and owners should secure

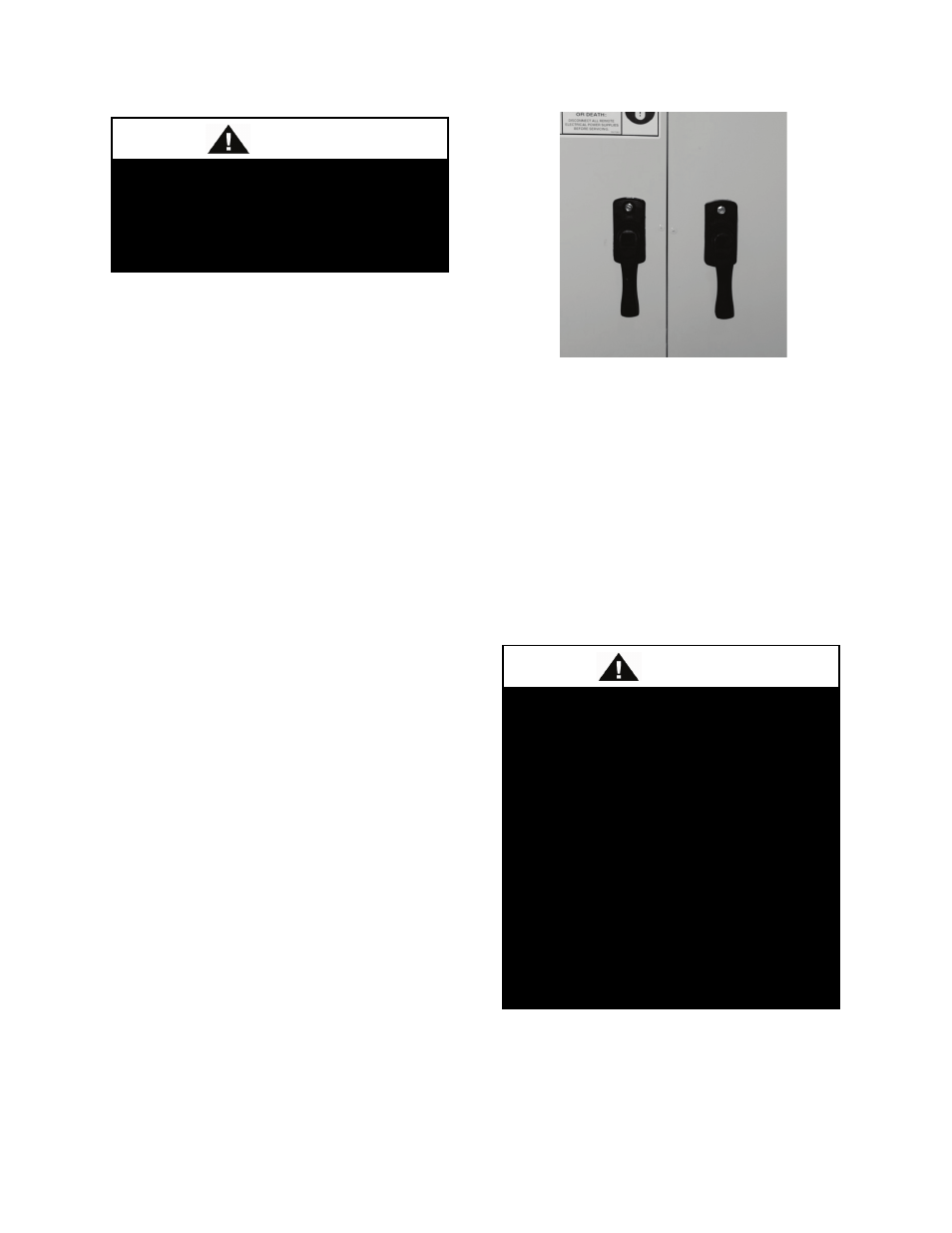

all doors with locks or nuts and bolts to

prevent unauthorized access.

The warranty card must be completed in full

and returned to AAON not more than 3

months after unit is delivered.

Figure 1 - Lockable Handle

Storage

If installation will not occur immediately

following delivery, store equipment in a dry

protected area away from construction

traffic and in the proper orientation as

marked on the packaging with all internal

packaging in place. Secure all loose-shipped

items.

Direct Expansion (DX) Systems

All water-cooled condenser DX systems are

factory assembled, leak tested, charged with

R-410A refrigerant, and run tested.

Failure to observe the following

instructions will result in premature

failure of your system and possible

voiding of the warranty.

WARNING

COMPRESSOR CYCLING

5 MINUTE MINIMUM OFF TIME

To prevent motor overheating

compressors must cycle off for a

minimum of 5 minutes.

5 MINUTE MINIMUM ON TIME

To maintain the proper oil level

compressors must cycle on for a

minimum of 5 minutes.

The cycle rate must not exceed 6

starts per hour.

WARNING