Caution – AAON CN-140 User Manual

Page 31

31

For units equipped with low ambient (0°F)

option see the special charging instructions

at the end of this section.

Checking Liquid Sub-cooling

Measure the temperature of the liquid line as

it leaves the condenser coil.

Read the gauge pressure at the liquid line

close to the point where the temperature was

taken. You must use liquid line pressure as it

will vary from discharge pressure due to

condenser coil pressure drop.

Convert the pressure obtained to a saturated

temperature using the appropriate refrigerant

temperature-pressure chart.

Subtract

the

measured

liquid

line

temperature from the saturated temperature

to determine the liquid sub-cooling.

Compare calculated sub-cooling to the table

below for the appropriate unit type and

options.

Checking Evaporator Superheat

Measure the temperature of the suction line

close to the compressor.

Read gauge pressure at the suction line close

to the compressor.

Convert the pressure obtained to a saturated

temperature using the appropriate refrigerant

temperature-pressure chart.

Subtract the saturated temperature from the

measured suction line temperature to

determine the evaporator superheat.

For refrigeration systems with tandem scroll

compressors, it is critical that the suction

superheat setpoint on the expansion valve is

set with one compressor running. The

suction superheat should be 10-13°F with

one compressor running. The suction

superheat

will

increase

with

both

compressors

in

a

tandem

running.

Inadequate suction superheat can allow

liquid

refrigerant

to

return

to

the

compressors which will wash the oil out of

the compressor. Lack of oil lubrication will

destroy a compressor. Liquid sub-cooling

should be measured with both compressors

in a refrigeration system running.

Compare calculated superheat to Table 7 for

the appropriate unit type and options.

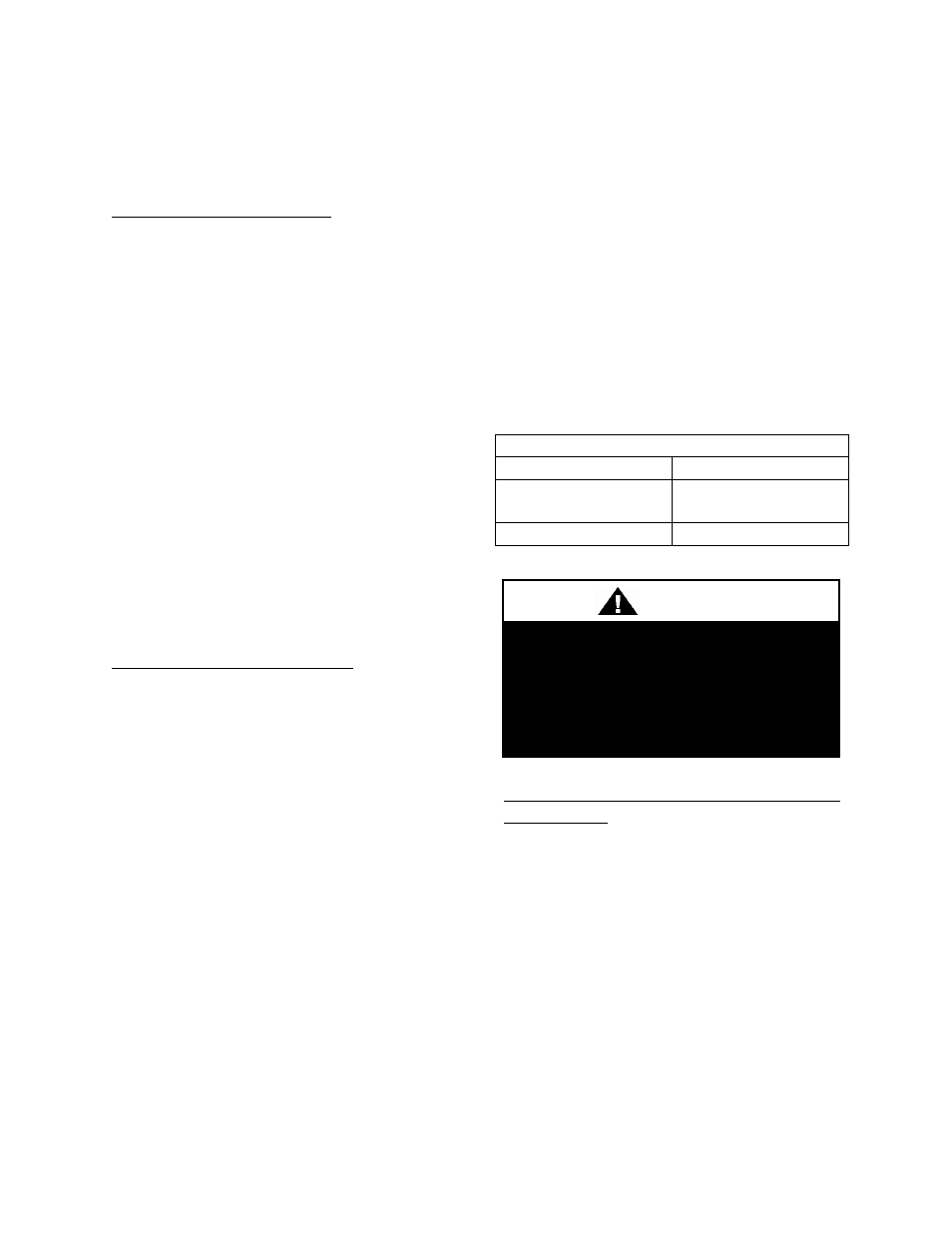

Table 7 - Acceptable Refrigeration Circuit

Values

Air-Cooled Condenser

Sub-Cooling

12-18°F

Sub-Cooling with

Hot Gas Reheat

15-22°F

Superheat

8-15°F

Adjusting

Sub-cooling

and

Superheat

Temperatures

The system is overcharged if the sub-cooling

temperature is too high and the evaporator is

fully loaded (low loads on the evaporator

result in increased sub-cooling) and the

evaporator

superheat

is

within

the

temperature range as shown in Table 7 (high

superheat results in increased sub-cooling)

Correct an overcharged system by reducing

the amount of refrigerant in the system to

lower the sub-cooling.

Expansion valves must be adjusted

to approximately 10-15°F of suction

superheat. Failure to have sufficient

superheat

will

damage

the

compressor and void the warranty.

CAUTION