Aaon, inc, Servicing, trouble shooting & maintenance – AAON RK-60 User Manual

Page 8

8

SERVICING, TROUBLE SHOOTING & MAINTENANCE

LUBRICATION

All original blower motors and bearings are furnished

with an orginal factory charge of lubrication. Some

applications will require that bearings be re-lubricated

periodically. The schedule will depend on the operating

duty, temperature variations or other severe atmospheric

conditions.

Bearings should be re-lubricated when at normal oper-

ating temperatures, but not running. Rotate the fan

shaft by hand and add only enough grease to purge the

seals. DO NOT OVERLUBRICATE.

Recommended greases are:

SHELL OIL - DOLIUM R

CHEVRON OIL - SRI No. 2

TEXACO INC. - PREMIUM RB

SERVICE

In the event the unit is not functioning correctly and a

service company is required, a company with service

technicians qualified and experienced in both gas, elec-

tric heating and air conditioning be permitted to service

the systems in order to keep warranties in effect. The

service tech may call the factory if assistance is required.

BEFORE CALLING, HE SHOULD HAVE THE MODEL

AND SERIAL NUMBER OF THE UNIT AVAILABLE

FOR THE CUSTOMER SERVICE DEPARTMENT TO

HELP ANSWER QUESTIONS REGARDING THE

UNIT.

AAON, Inc.

Phone: 918-583-2266

Fax: 918-382-6364

Customer Service Department

COMMON CAUSES OF REDUCED AIR FLOW

A.

DIRTY FILTERS - Filters must be inspected and

replaced on a regular basis. It is strongly recommended

that the media be replaced monthly. Clean filters are

your best insurance against premature system break-

down. Do not permit the unit to be operated unless the

filters are in place. Operation of the unit without filters

will result in a clogged evaporator coil - a very expensive

service job to correct.

B.

OBSTRUCTION TO AIR FLOW - Supply and

return air grilles must be kept clear so air can be freely

discharged and drawn from the system.

CLEANING

Inspect unit interior at the beginning of each heating

and cooling season and as operating conditions require.

COILS

Evaporator coil(s) should be inspected and cleaned an-

nually to ensure there is no obstruction to air flow.

Condenser coil(s) should be inspected monthly. Clean

condenser coils annually and as required by location or

outdoor air conditions.

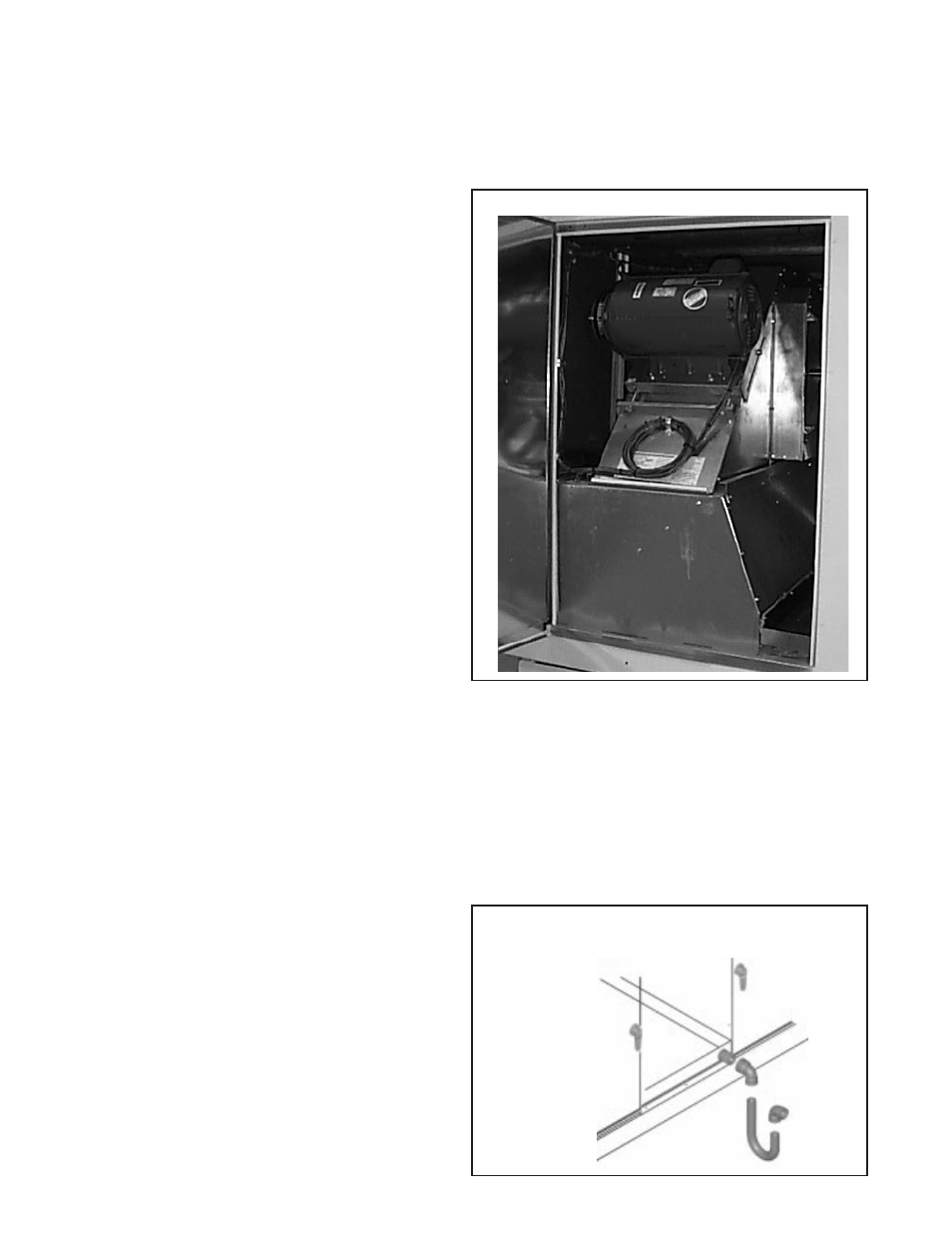

BLOWER

Inspect blower and blower section to keep free of dust or

debris. TURN OFF POWER BEFORE ATTEMPTING

TO CLEAN BLOWER WHEEL.

Typical slide-out blower section

CONDENSATE PIPING

Drain pans in any air conditioning equipment, even

when they have a built-in slope to the drain, will have

moisture present and will require periodic cleaning to

prevent any build up of algae of bacteria.

Cleaning of the drain pans will also prevent any

possible plugging of the drain lines and an over-

flow of the pan itself. All cleaning of the drain

pans and inside of the equipment should be done

by qualified personnel.

Typical 'P' trap

FOR PROPER UNIT OPERATION, DRAIN TRAP

MUST BE INSTALLED AS SHOWN.