D-series, Application, Measuring ranges – Delta Controls D-Series TDSSP User Manual

Page 2: Recommendations

www.delta-controls.com

D-Series

Models: S-P

Application

The diaphragm seal is a pressure transmitting, diaphragm-type device. The pressure signal is sent to the cooperating

pressure measuring device (pressure transmitter, pressure gauge) through manometric liquid filling the space between the

separating diaphragm of the seal and the pressure measuring device. The diaphragm seal task is to isolate the pressure

measuring device from damaging impacts caused by either medium or installation:

s

Low or high temperature, increased viscosity, and impurities

s

Vibrations of the installation (remote diaphragm seal)

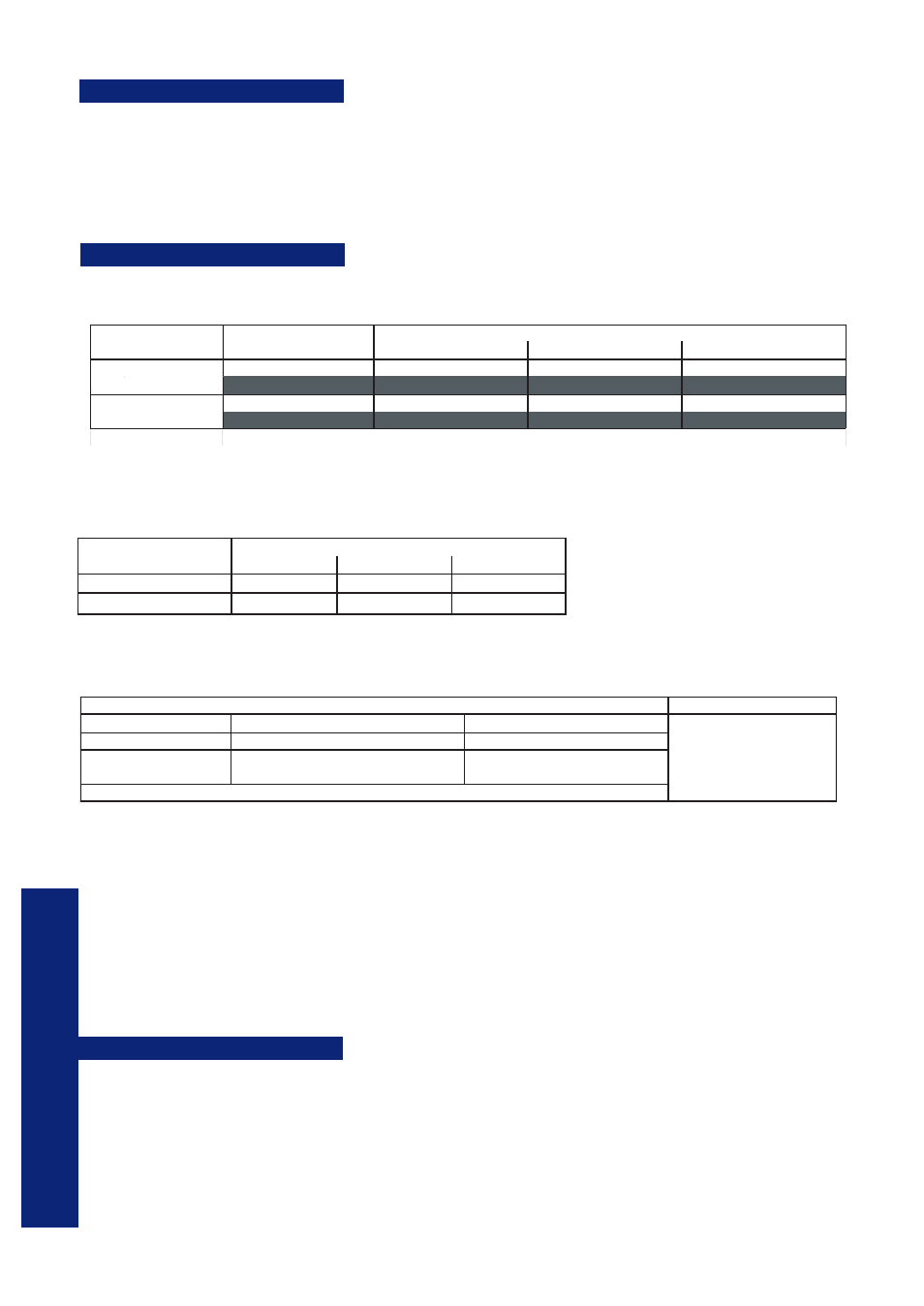

Measuring Ranges

Important:

- contact face in diaphragram seal DN50 have a milled slot for a gasket (acc. to DIN 2512 FormN). Version without any

slot available on request. (acc. to DIN 2526 FormE)

- standard outlet capillary from flange:

direct mounted diaphragm seal - axial

remote mounted diaphragm seal - radial

Recommended minimum measuring range (bar),

depending on the type of the set: pressure measuring device - diaphragm seal

Pressure

measuring device

Diaphragm

seal type

Diaphragm seal version

DN50 / 2’’

DN80 / 3’’

DN100 / 4’’

Smart

transmitters ∗

direct

0.25

0.1

0.1

remote (2 m)

1

0.25

0.25

DPCE-28

direct

0.1

0.1

0.1

remote (2 m)

1

0.25

0.25

Additional absolute zero error resulting from ambient temperature fluctuations,

depending on the type of the set: pressure transmitter - diaphragm seal

Diaphragm seal type Absolute zero error per 10°C for the diaphragm seal

DN50 / 2’’

DN80/ 3’’

DN100 / 4’’

direct

0.5 mbar

0.4 mbar

0.4 mbar

remote (2 m capillary)

3

mbar

1

mbar

1

mbar

Temperature range of measured medium

Remote diaphragm seal

Direct diaphragm seal

Manometric liquid

Underpressure measurements

Overpressure measurements

high -temperature (DC)

-10...150°C

-10...315°C

-30...150°C

low-temperature (AK)

not recommended for measure ment

of pressures < 0.5 bar ABS

-60...200°C

Note: When operating with an amb

ient temperature of < -15°C, heating of capillaries filled with DC fluid is recommended.

Maximum pressure for PN40 – 40 bar

Maximum pressure for ANSI 150 – 150 psi

Material of diaphragm and flange 316Lss

Special versions

- Other standard ANSI or DIN

- Filled with edible oil (medium temp. -10...150°C)

- Direct diaphragm seal for medium temp. over 150°C

- Others

Recommendations

The essential metrological problem with diaphragm seal operational use is the absolute thermal zero error, which results

from the thermal expansion of the manometer liquid. The expansion effect must be compensated for by the separating

diaphragm’s flexibility.

To minimise this effect, it is advisable to:

s

Use capillaries which are as short as possible - in this way, the volume of manometer liquid will be reduced

s

Use seals with greater diameters in order to maximise the flexibility of the separating diaphragm

s

Place the capillaries in places in which the temperature fluctuations will be minimal

*The ranges given in the table for the smart transmitters should be taken as set ranges

An additional zero error, resulting from

temperature fluctuations in a medium,

depends on the temperature gradient in

the oil-based diaphragm sealing

system. The error value is, in any case,

significantly smaller than the error value

shown in the table.