Operation adjustments, Wiring (continued...) – Delta Controls T01 User Manual

Page 2

002522-SENTRY-C : FEB 2012

www.delta-controls.com

IF

HINGE

IS

DAMAGED,

INGRESS

PROTECTION

LEVEL

COULD

BE

COMPROMISED.

A single M20 or ½”NPT electrical entry is provided,

into which a cable gland can be assembled. Select a

suitable cable gland which will maintain the IP rating of

the instrument.

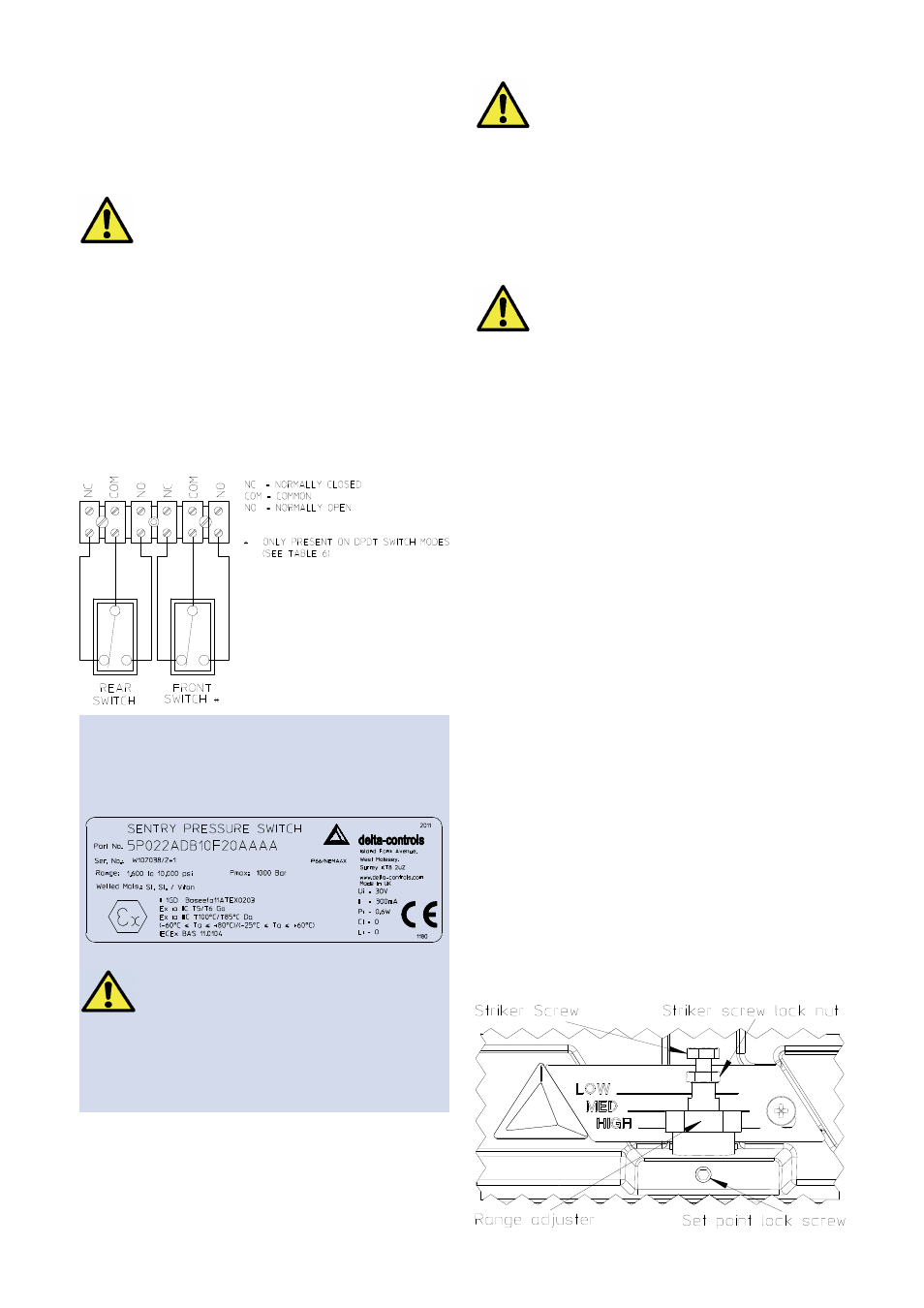

The three switch terminals are clearly marked

“NORMALLY CLOSED”, “NORMALLY OPEN” and

“COMMON”.

For products supplied with terminal blocks, the follow-

ing diagram can be used as a guide for wiring.

Insert bare wires fully into the terminal block and

tighten securely. Keep wiring tails to a minimum and

check that wires do not interfere with the operating

mechanism. Use the earthing / grounding points

provided.

BEFORE CLOSING THE LID:

Ÿ ENSURE WIRE IS CLEAR OF ALL

MOVING PARTS.

Ÿ CHECK THAT THE GASKET IS SEATED

CORRECTLY AND IN GOOD CONDITION

Ÿ ENSURE THAT WIRES DO NOT TOUCH

THE LID AS IT IS CLOSED

Close the lid, being careful not to trap any wires in

doing so. Tighten the lid locking screw until the lug on

the top of the lid makes contact with the enclosure lug.

OPERATION

Adjustments

Pressure and Temperature Switches are supplied

calibrated at the midpoint of their range and to a falling

pressure or temperature unless otherwise specified.

To re-calibrate:

1. Isolate the instrument from the process and power.

2. Loosen lid lock screw and open the lid.

3. Slacken the set point lock screw.

4. Using a suitable spanner, rotate the range

adjuster clockwise to increase the set point and

counter-clockwise to decrease the set point.

5. Tighten the set point lock screw.

6. Close the instrument lid and tighten lid lock screw

Note: For accurate setting of Pressure and Differential

Pressure models, a suitable pressure gauge must be

used in conjunction with the above procedure. Do not

attempt to set the switch outside the scale limits. For

Temperature models a suitable calibrated temperature

source should be used.

Though the unit may be set anywhere within its range,

for optimum performance, it is good practice to have a

set point value between 25% and 75% of span.

The striker screw and lock nut are factory set and

should not be adjusted. Should these parts be acci-

dentally loosened, please contact Delta for assistance.

Wiring (continued...)

Undo the single lid retaining screw and allow the

hinged lid to rest in an open position. Be careful not to

apply excessive pressure on the opened lid to avoid

damage to the hinge.

THE LID LOCKING SCREW MUST BE

TIGHTENED FULLY IN ORDER THAT

ELECTRICAL

CONNECTION

IS

MADE

BETWEEN THE LID AND THE ENCLOSURE

THE MICRO SWITCHES MAY BE SINGLE OR

DOUBLE

POLE,

DOUBLE

THROW

SWITCHES AND ALL THE ELECTRICAL

CONNECTIONS MUST FORM PART OF THE

SAME INTRINSICALLY SAFE CIRCUIT.

WHERE TWO MICRO SWITCHES ARE

FITTED, THEN ALL THE ELECTRICAL

CONNECTIONS MUST FORM PART OF THE

SAME INTRINSICALLY SAFE CIRCUIT.

Notes for Intrinsic Safety

Input limitations for intrinsic safety:

Ui = 30V, Ii = 300mA, Pi = 0.6W

Example label: