CHIEF SL151 Series User Manual

Page 8

SL151

Installation Instructions

8

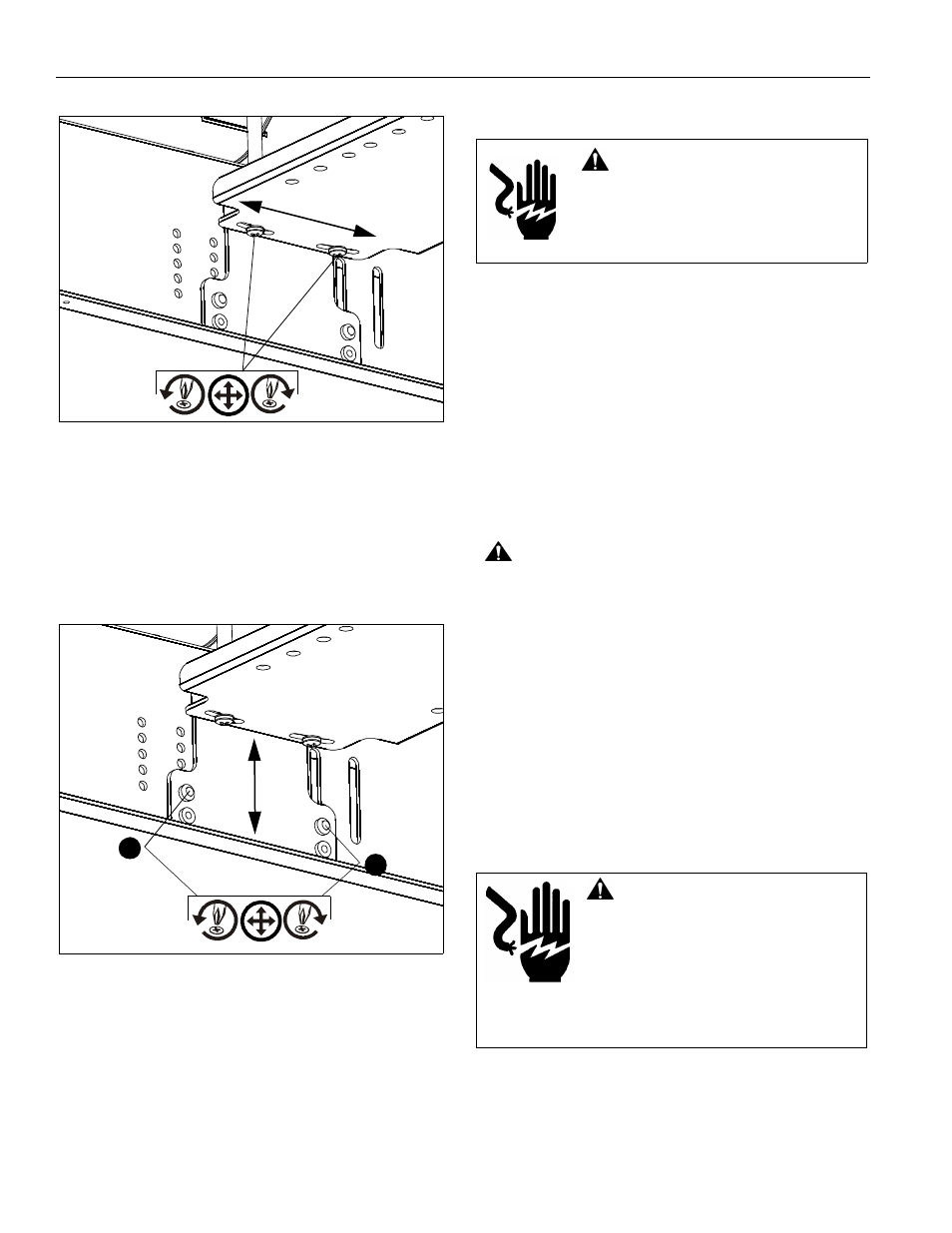

Figure 12

3.

PITCH

•

Remove and save back screw on each side.

•

Adjust vertically, as required.

•

Reinstall and tighten screws. (See Figure 13)

4.

VERTICAL

•

Remove and save front screw on each side.

•

Adjust vertically, as required.

•

Reinstall and tighten screws. (See Figure 13)

Figure 13

5.

ROLL (Horizontal Tilt)

•

Shift bracket up or down in the side holes on one side

or the other by removing screws.

•

Adjust and tighten screws on bracket. (See Figure 13)

Connecting Control Wiring

1.

Unplug the SL151’s test cord (used for testing).

2.

Remove the jumper wire and supplied push button wiring

(previously installed in the Pre-Test Lift before Installation

section) from the external terminal block. (See Figure 3)

3.

Connect control wiring following instructions included with

the controller and information in Table 1: Wiring Table

NOTE:

Any knockouts removed in the SL151 must be

replaced with a supplied rubber grommet (G).

4.

Feed the video and/or communications cables through the

knockout in the rear or top of the lift and connect it to the

projector.

NOTE:

Ensure there is enough slack in the cables to allow for

up and down movement of the lift.

5.

Secure cables as necessary using supplied mounting pads

(E) and cable ties (B).

CAUTION:

KEEP SL151 OPEN WHILE PROJECTOR IS

RUNNING OR IN COOLING MODE! Premature bulb failure

or damage to electrical components may occur if lift closes.

NOTE:

If SL151 is cycled up and down repeatedly the motor’s

thermal overload protection will stop operation.

Operation will resume when the thermal overload

resets (usually within 3 to 5 minutes).

Connecting to Power Supply

IMPORTANT ! :

This product must be connected to a

grounded metal, permanent wiring system, or an equipment-

grounding conductor must be run with the circuit conductors

and connected to the equipment-grounding terminal or lead on

the product.

1.

Disconnect and remove power inlet from interior junction

box.

2.

Hardwire unit to a 120V 60Hz 12-amp power source.

NOTE:

This unit was designed to have conduit run directly into

the back of the interior junction box.

3

4

WARNING:

All wiring should be

performed by a licensed electrician following

the National Electric Code, ANSI/NFPA, and

Canadian Electrical Codes, Part 1.

WARNING:

FAILURE TO

DISCONNECT AND TERMINATE POWER

LEADS PROPERLY MAY RESULT IN

PERSONAL INJURY OR EQUIPMENT

DAMAGE!! Licensed electrician must

disconnect and terminate the leads to the

power cord receptacle, and must hard wire

the SL151 to a 12-amp power source.