J&M 1326-22T User Manual

Page 10

8

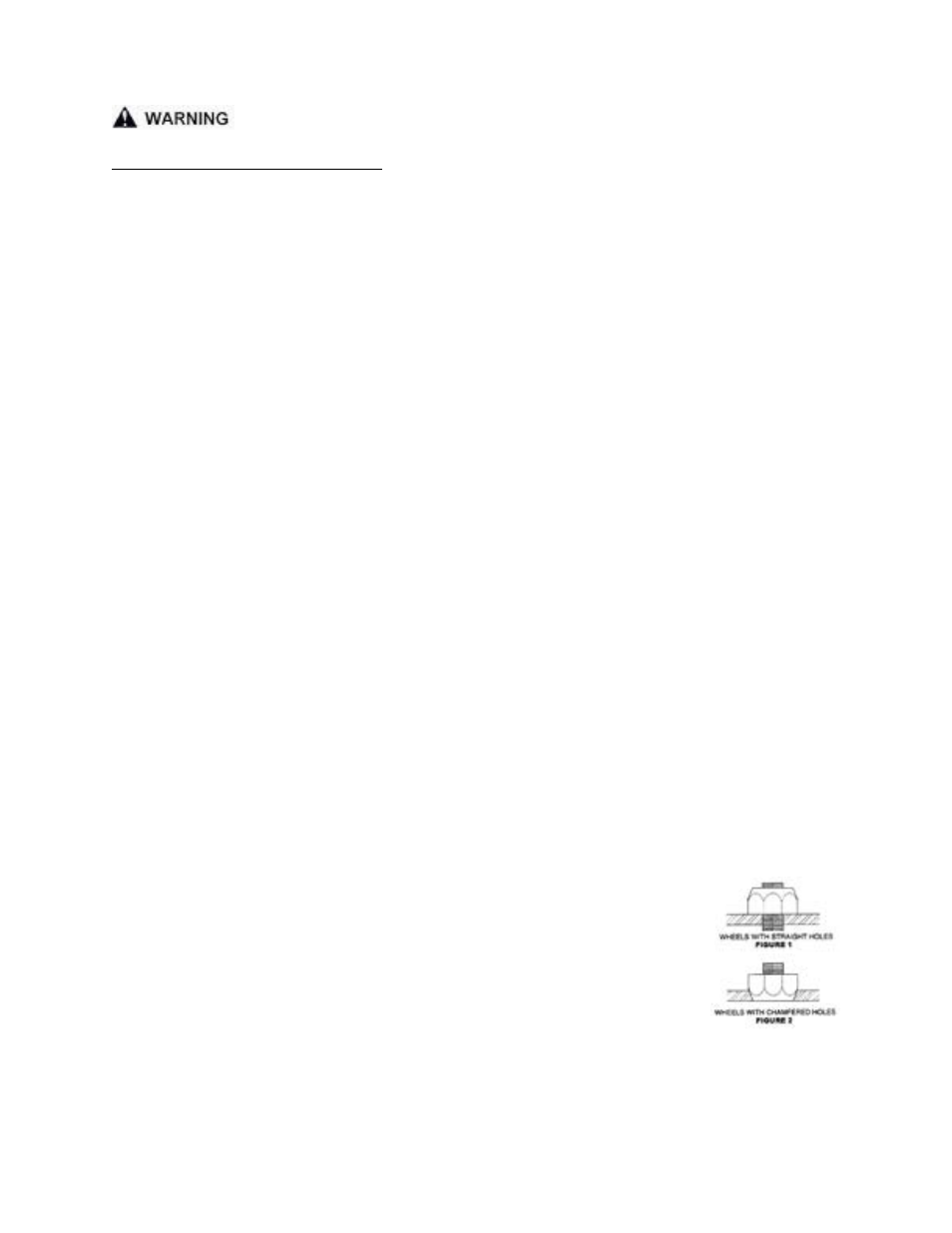

The drawing shows the proper ways of mounting the wheels using Budd-type nuts.

The wheels supplied with your Grain Cart have straight holes and the Budd nuts will

be mounted according to Figure 1. Wheels that are improperly installed on the grain

cart, resulting in product failure, will nullify warranty and shift the burden of liability to

the owner/operator of the equipment. We suggest that you inspect your wheel nuts

to make sure that they are properly installed. Also, check the wheel nuts on a regular

basis to ensure they are tight.

INITIAL OPERATION/MAINTENANCE

BE CERTAIN THAT ALL POWER IS SHUT OFF BEFORE SERVICING THE GRAIN CART.

Before the grain cart is put into service:

Has the gearbox been properly filled with EP-80-90 gearbox lubricant?

Has the hanger bushing assembly at the auger hinge been greased and have all grease points at the hinge

area been greased?

Are all bearings on the drive line properly greased? Are all set screws in the bearings and U-Joints tight?

Has the power-take off been properly greased at all points including cross bearings? Has the universal joint

at the gearbox been greased?

IMPORTANT: Has the slip clutch on the PTO been serviced? If the slip clutch is left unchecked, damage to

the power-take-off and drive shaft may result. Before using the grain cart, loosen the bolts around the slip

clutch. Make sure that the friction plates turn free of each other and are not corroded together. Retighten

the tension bolts. Run the auger system EMPTY and check for proper engagement of the slip clutch.

Have all nuts, bolts, bearings, and braces been properly fastened?

Have the safety instructions been read and clearly understood by the operator(s) of this machine?

WHEEL NUTS - Are the wheel nuts properly fastened (torque to 600 Lbs.-Ft. for standard 22 MM wheel

studs and nuts)?

They should be checked after each load during initial operation of the cart and then

after every 10 hours of use. Failure to do so may damage wheel nut seats. Once seats are damaged,

it will become impossible to keep nuts tight.

LIGHTING AND SAFETY DECALS - Are the rear, amber extremity lights properly positioned? Extend lights

within 16” of the left and right extremities of the grain cart. Is a SMV Emblem attached to the grain cart?

Are the lights working properly? Are all reflective decals clean and visibile? Are they positioned

correctly?

Check the PTO overlap length. Overlap length may vary depending on tractor model. Try to obtain the

greatest possible overlap without bottoming out in the maximum operating condition.

Too much overlap

may cause PTO to bottom out and damage driveline. See OPERATING INSTRUCTIONS for recom-

mended overlap.

TIRE PRESSURE - Are the tires properly inflated? The following is to be used as a general guide for tire

inflation for cyclic use. Figures can vary depending on specific brand of tire used.

It is important that tires

are inspected before and after unit is loaded. Start with the minimum pressure indicated. The tire should

stand up with no side wall buckling or distress as tire rolls.

Do Not Exceed Maximum Recommended

Tire Pressure.

Tire

Size Pressure

76x50.00, R-1, 20 ply 50 psi

VERY IMPORTANT:

Under no circumstances is it recommended to tow a loaded grain cart in excess of 8 m.p.h.