Repair and assembly, Pump wet end removal, Tools needed – All-Flo A200-NAA-VVYV-000 2 Aluminum User Manual

Page 14

all-flo.com

14

REPAIR AND ASSEMBLY

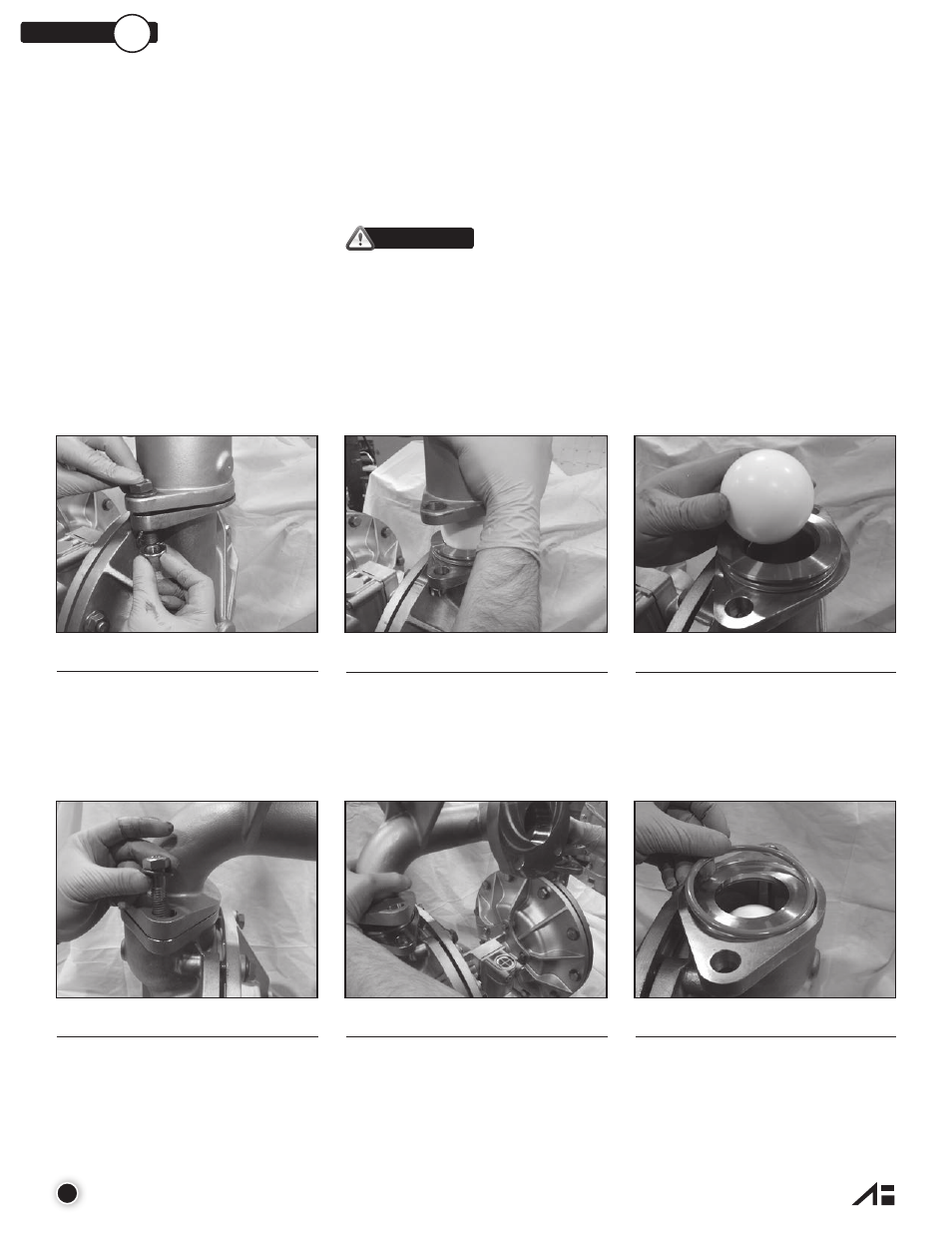

PUMP WET END REMOVAL

STEP 1

Using the 3/4 inch wrench remove

four “Hex-Head Cap Screws (1/2”-

13x2”)”, four “Flat Washers (1/2”)”

and four “Flanged Hex Nut (1/2”-

13)” from the “Discharge Manifold”.

STEP 2

Remove the “Discharge Manifold”.

STEP 3

Remove the “O-Ring”, “Valve Seat”

and “Ball”.

TOOLS NEEDED

1) One Wrench, 7/16 Inch

2) Two Wrenches, 1/2 Inch

3) Two Wrenches, 3/4 Inch

4) Two Wrenches, 1 Inch

5) One Socket Wrench, 1-1/16 Inch

6) One Spanner Wrench, 3/4 Inch

(May Be Required)

WARNING

Prior to servicing the pump, ensure that the air and

fluid lines are closed and disconnected. While wearing personal

protective equipment, flush, drain and process liquid from the pump

in a safe manner.

STEP 4

Using the 3/4 inch wrench remove

four “Hex-Head Cap Screws (1/2”-

13x2”)”, four “Flat Washers (1/2”)”

and four “Flanged Hex Nut (1/2”-

13)” from the “Suction Manifold”.

STEP 5

Remove the “Suction Manifold”.

STEP 6

Remove the “O-Ring”, “Valve

Seat” and “Ball”.

SECTION

7

- A200-NAA-TTYT-000 2 Aluminum A200-NAA-SSPE-000 2 Aluminum A200-NAA-NNPN-000 2 Aluminum A200-NAA-GTPN-000 2 Aluminum A200-NAA-GGPN-000 2 Aluminum A200-BAA-VVYV-000 2 Aluminum A200-BAA-TTYT-000 2 Aluminum A200-BAA-SSPE-000 2 Aluminum A200-BAA-NNPN-000 2 Aluminum A200-BAA-GTPN-000 2 Aluminum A200-BAA-GGPN-000 2 Aluminum A200-EA3-VV3V-000 2 316 Stainless Steel A200-EA3-TT3T-000 2 316 Stainless Steel A200-EA3-SS3E-000 2 316 Stainless Steel A200-EA3-GG3N-000 2 316 Stainless Steel A200-CA3-VV3V-000 2 316 Stainless Steel A200-CA3-TT3T-000 2 316 Stainless Steel A200-CA3-SS3E-000 2 316 Stainless Steel A200-CA3-GG3N-000 2 316 Stainless Steel