Shutdown, Daily check, Maximum torque specifications – All-Flo T038-NHT-PTTT-000 3/8 PTFE User Manual

Page 13: Caution

13I All-Flo Pump Co.

Shutdown

Close the air valve of the pump and shut off the supply air.

Daily check

Before starting pump operation, conduct the following check procedures every day. In case there appears any

irregularity, do NOT start running the pump until the cause of the irregularity has been determined and

corrective measures have been taken.

a) Make sure that there is no leakage of fluid from any connection part or the pump.

b) Make sure that there are no cracks in the pump casing or piping.

c) Check the tightness of every bolt of the pump.

d) Make sure that the connection parts of the piping and peripheral equipment are not loose.

e) Make sure that any parts of the pump that are to be replaced at regular intervals have been changed.

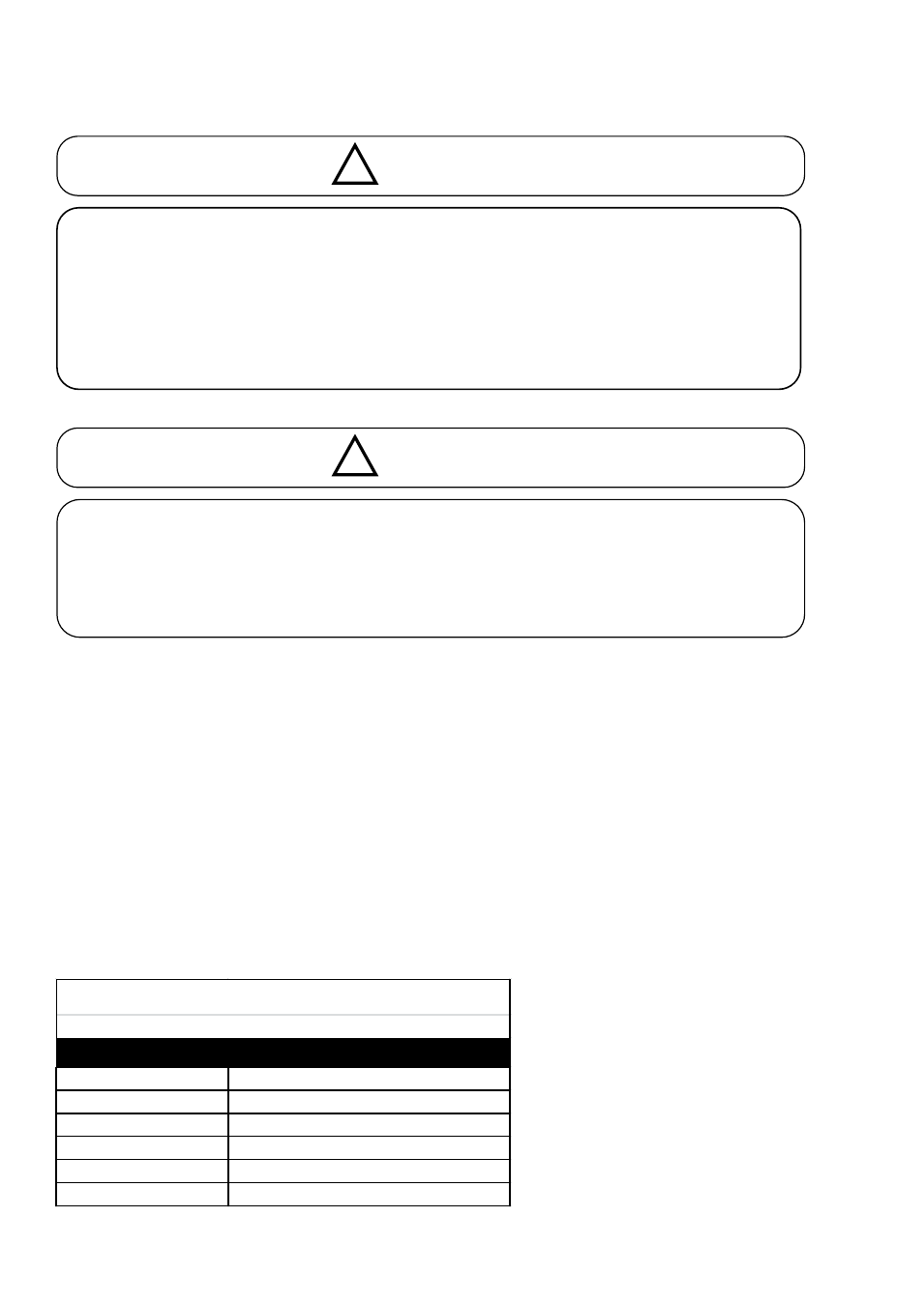

Pump Size

T025

18 in-lbs (2 N-m)

T038

44 in-lbs (5 N-m)

T050

62 in-lbs (7 N-m)

T100

97 in-lbs (11 N-m)

T150

133 in-lbs (15 N-m)

T200

168 in-lbs (19 N-m)

Maximum Torque Specifications

Torque values for housing bolts

!

CAUTION

!

CAUTION

!

The pump can be shut down with the flow valve closed while air is being supplied. However DO NOT leave

the pump in this condition for many hours without supervision - there is a risk of a leak from the pump or

piping, and fluid may continue flowing out of the position of leakage.

!

When the pump is shut down while pumping slurry, particulate matter contained in the slurry will be

deposited and get stuck inside the out chamber. Therefore after finishing work the pump must be cleared of

the remaining fluid. Otherwise when starting the pump again, the diaphragm may get damaged and the

center rod may bend.

!

Keep a vessel below the relief valve for any drain off.

!

Be careful! - Fluid under pressure will gush out the moment you open the valve.

!

If the pump is unused for a prolonged period, purge and clean it.

- T038-BHT-PTTT-000 3/8 PTFE T150-NHT-PTTT-000 1 1/2 PTFE T150-DHT-PTTT-000 1 1/2 PTFE T150-BHT-PTTT-000 1 1/2 PTFE T150-AHT-PTTT-000 1 1/2 PTFE T150-BHT-PTTT-000 High Purity PTFE T050-NHT-PTTT-000 1/2 PTFE T050-DHT-PTTT-000 1/2 PTFE T050-BHT-PTTT-000 1/2 PTFE T050-AHT-PTTT-000 1/2 PTFE T100-NHT-PTTT-000 1 PTFE T100-DHT-PTTT-000 1 PTFE T100-BHT-PTTT-000 1 PTFE T100-AHT-PTTT-000 1 PTFE T200-NHT-PTTT-000 2 PTFE T200-DHT-PTTT-000 2 PTFE T200-BHT-PTTT-000 2 PTFE T200-AHT-PTTT-000 2 PTFE T200-NHT-PTTT-000 High Purity PTFE T200-DHT-PTTT-000 High Purity PTFE T200-BHT-PTTT-000 High Purity PTFE T200-AHT-PTTT-000 High Purity PTFE T150-NHT-PTTT-000 High Purity PTFE T150-DHT-PTTT-000 High Purity PTFE T150-AHT-PTTT-000 High Purity PTFE T100-NHT-PTTT-000 High Purity PTFE T100-DHT-PTTT-000 High Purity PTFE T100-BHT-PTTT-000 High Purity PTFE T100-AHT-PTTT-000 High Purity PTFE T050-NHT-PTTT-000 High Purity PTFE T050-DHT-PTTT-000 High Purity PTFE T050-BHT-PTTT-000 High Purity PTFE T050-AHT-PTTT-000 High Purity PTFE T038-NHT-PTTT-000 High Purity PTFE T038-BHT-PTTT-000 High Purity PTFE T025-NHT-PTTT-000 High Purity PTFE T025-BHT-PTTT-000 High Purity PTFE T025-BHT-PTTT-000 1/4 T025 PTFE T025-NHT-PTTT-000 1/4 T025 PTFE