3 loading the feed (press application) – PA Industries Edge Sequential Servo Roll Feed SRF-100/125/200/300/400/500/600 - Installation Manual User Manual

Page 6

ULTRA EDGE SEQUENTIAL SERVO ROLL FEED 6/3/2002

6

1.3 LOADING THE FEED (PRESS APPLICATION)

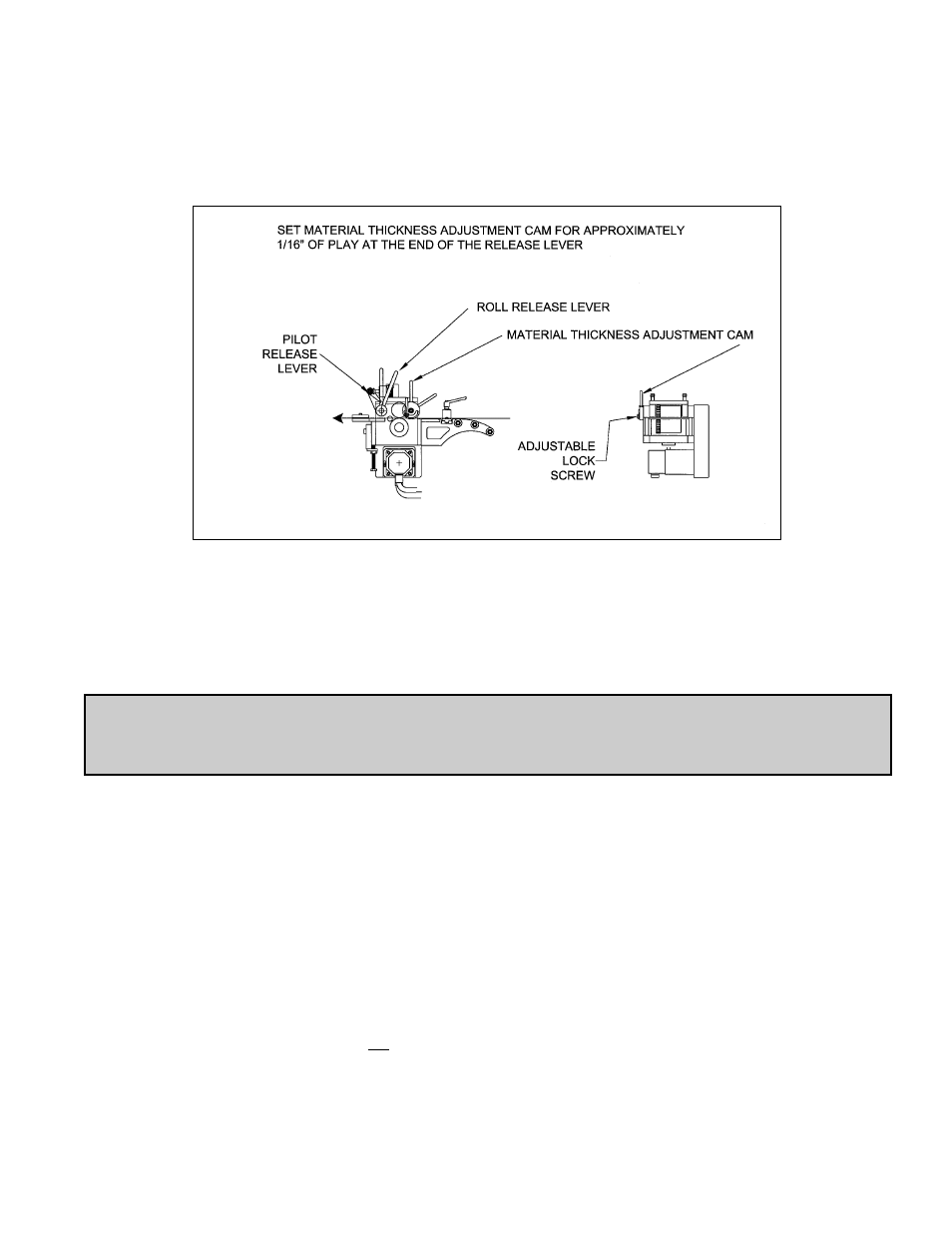

FIGURE 3

Prior to this step, the electrical control must be powered up and all needed parameters are loaded.

(Refer to the Ultra Edge Sequential Servo Feed Operating Manual.)

NOTE:

This example is based on using PLS (Programmable Limit Switch), but all PLS timing notes can be easily

translated to other forms of timing.

1. Put

the

Ultra Edge Sequential control into “MANUAL MODE”. Record the present settings of the Feed

Cam, Reset Cam, and Pilot Release Cam into a job set-up record sheet for future reference to the job.

2. Adjust the roll clamping force by pre-loading the two die springs located on top of the feed housing. Normal

setting for the roll force spring pre-load is two full turns clockwise from finger tight (factory preset). Be sure

to use the jam nut to lock the setting.

3. Open the feed rolls by pulling on the Roll Release Lever. Insert the material through the feed rolls and close

the feed rolls by releasing the Roll Release Lever.

4. Adjust the material thickness using the Material Thickness Adjustment Cam and Adjustable Lock Screw.

Refer to the FIGURE 3 for proper setting.

5. Using

the

Jog Forward button on the jog pendant, advance the material up to the entrance of the die (far

enough where the punches would not pierce the material).

6. Check the vertical alignment of the strip. If necessary, adjust the pass line of the feeder so that the material is

at the proper height.

7. Assuming that the press shut height and the tool are set up properly, jog the press one or two strokes without