Dings Magnetic Group 2 PULLEY EDDY CURRENT SEPARATOR User Manual

Page 6

MAINTENANCE

CAUTION: Rare earth magnets in the magnetic

rotor assembly are extremely powerful. They can

project magnetism through a considerable dis-

tance and exert strong pulling force on magnetic

metals. Use of iron or steel tools near the magnet

could cause injury to personnel or damage to the

separator.

I

MPORTANT

D

AILY

M

AINTENANCE

The magnetic rotor should be inspected routinely to ensure

that no iron or ferrous metal is attached to the shell of the

rotor beneath the conveyor belt. This metal may wear a

groove in the surface of the outer shell and cause it to fail

prematurely. Daily inspection is recommended, although it

depends on your application and conditions.

The ceramic tile used by Dings on the outside of the

fiberglass shell is the most wear-resistant surface available,

but you will still need to inspect the shell daily and remove

any iron particles in order to ensure a long life for the sepa-

rator.

To inspect the wear shell:

1) Turn off the magnetic rotor and the conveyor belt

and lock out power. Allow them both to come to a

complete stop. The conveyor belt will continue to

run for several minutes after the switch has been

turned off. Lock out power.

CAUTION: You should wear safety glasses,

a face shield, or some other type of eye

protection before proceeding with the

inspection.

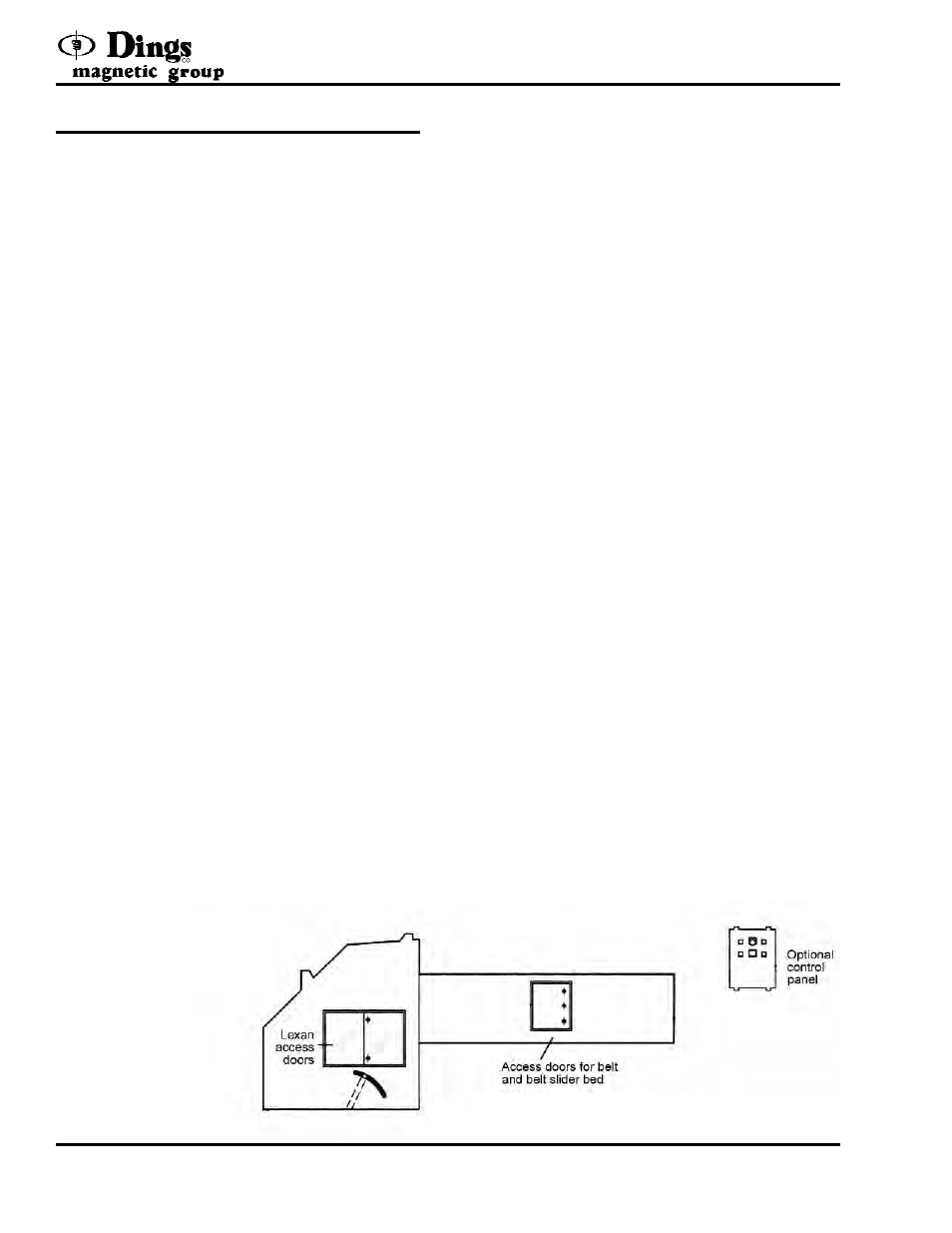

2) Open the access doors (Fig. 10) and inspect the belt

and the wear shell. There should not be any holes in

the belt, nor any grooves in the wear shell of the

rotor.

3) Rotate the shell slowly by hand and remove any

iron particles which may be attached to it.

4) Continue to rotate the pulley slowly and remove

any pieces of steel or iron sticking in the belt.

Inspect the belt for any signs of holes or wear

which may allow particles or iron to go through

the belt and onto the surface of the wear shell.

If the belt shows much wear or any holes,

it should be replaced with a new belt.

5) Inspect the belt position on the pulley to see if it

is tracking properly or if it needs to be adjusted.

Do not over-tighten when adjusting or damage

will occur to the wear shell.

6) Inspect the belt slider bed through the access

doors. If the slider bed shows signs of excessive

wear, it should be replaced.

Cleaning the Splitter

CAUTION: Stop the separator before cleaning

the splitter. It is dangerous to clean it when the

unit is running as the cleats on the belt may

cause injury. Lock out power.

It is very important to keep paper, rags, wire, plastic

bags, etc. from collecting on the splitter. This build-up

of debris can block the nonferrous metal, causing it to

fall into the nonmetallic discharge chute. To clean the

splitter:

1) Turn off the magnetic rotor and the conveyor

belt. Allow them both to come to a complete

stop. The belt of the conveyor will continue to

run for several minutes after the switch has

been turned off. Lock out power.

2) Open the two Lexan access doors on the side

of the discharge housing.

3) Use a wooden stick or dowel to clean off

the splitter.

CAUTION: Do not use a metal rod or any piece of

steel or iron as it will be attracted to the magnetic

rotor.

Figure 10 - Access Doors for

Inspection and Cleaning of

Components.

6