Eddy current separator – Dings Magnetic Group 2 PULLEY EDDY CURRENT SEPARATOR User Manual

Page 3

EDDY CURRENT SEPARATOR

OPERATION

CAUTION: Do not operate the separator with the

access doors open.

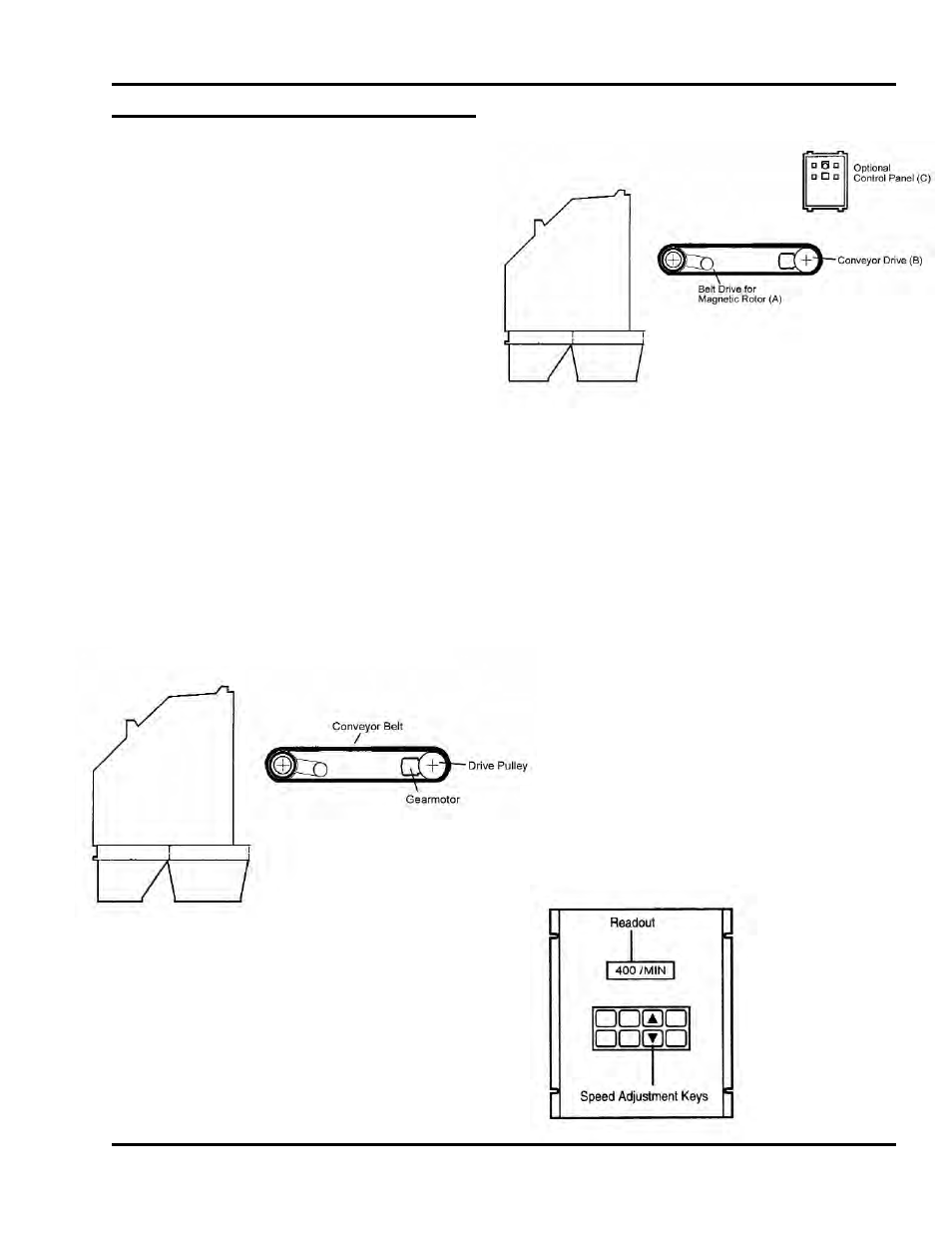

The separator has two motor drives (Fig. 3):

(A) fixed high speed drive which rotates the magnetic rotor

assembly;

NOTE: The rotor is a high inertia load on the rotor motor,

so special consideration must be taken during start-up.

The motor can be started no more than once in a 15

minute period. After shut down, allow the motor to rest

for at least 15 minutes before restarting.

(B) fixed speed drive which runs the conveyor belt at about

400 fpm.

Optional motor controls are located in the control panel (C).

Conveyor belt

Nitrile belt with thermowelded PVC “T”

cleats and PVC “C” sidewalls.

Conveyor belt pulley

Pulley is crowned and there is lagging on the

drive pulley.

Gearmotor.

Belt speed adjustment (if equipped)

See “Start-Up” on page 5 for more information

about belt speed.

If equipped with a variable frequency drive:

The conveyor belt speed is preset to 400 fpm.

The speed is adjustable at the drive from 198 to

440 fpm by pushing and holding one of the

arrow keys on the drive until the desired speed

is reached. The unit reads the speed of the belt

directly in fpm. (Eg: 400/MIN = 400 fpm).

For most applications, a belt speed of

approximately 400 fpm will result in the best

separation.

If equipped with a fixed-speed drive:

The belt speed is fixed at approximately

400 fpm.

Figure 3 - Motor Drives and Controls.

Figure 4 - Conveyor Belt and Drive.

Figure 5 - Variable Frequency (VF) Drive for

Conveyor Belt (Optional).

No keys other than speed

adjustment need to be

used, as the main control

panel (Fig. 7) controls the

VF drive. If other changes

to the drive’s programming

are needed, please refer to

the VF manual or consult

Dings. See wiring diagram

for factory settings on

the VF drive.

3