Maintenance – Dings Magnetic Group Self-Cleaning Permanent Overhead Magnet User Manual

Page 7

Revised May 19, 2014

MAINTENANCE

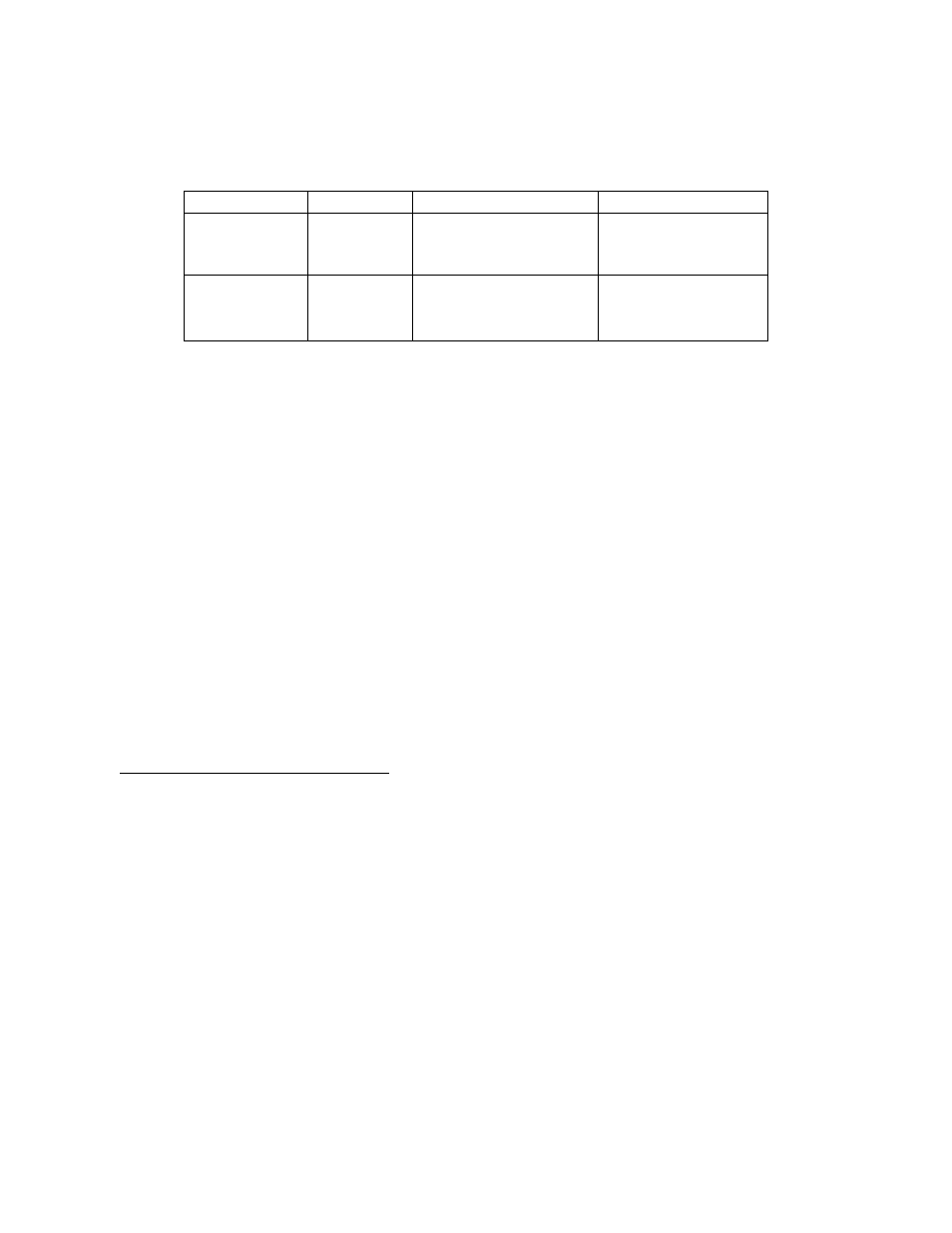

LUBRICATION SCHEDULE FOR OVERHEAD PERMANENT MAGNET

ITEM QUANTITY

BRAND

&

GRADE INTERVAL

Magnet

Gearmotor

1.9 Quarts

Mobilgear SHC 630

Synthetic Oil or

Equivalent

2,500 Hours

Magnet

Bearings

As

Required

Lithium Base NLG 1

Grade 2EP or

Equivalent

2-6 Months

DRIVE ASSEMBLY

GEARMOTOR - Inspect motor at regular intervals. Keep motor clean and the ventilation

openings clear of dust or other debris. See attached Nord Gearmotor manuals for specific

information.

BEARINGS

LUBRICATION - If conditions are clean, lubricate every 2 to 6 months. If dirty, lubricate

every 2 weeks or on a schedule consistent with other equipment in the same environment.

Lubricate with a lithium based grease conforming to NLGI Grade 2.

GENERAL - Periodically check hex head set screws and bearing bolts for tightness, tighten

if loose.

SELF-CLEANING BELT

BELT - Periodically inspect for signs of wear. If belt replacement instructions are needed,

contact factory.

FASTENERS - Periodically check for wear, especially on the underside. If fastener

replacement instructions are needed, contact factory.

TRACKING - If belt needs to be retracked, refer to belt tracking section below.

ZERO SPEED SWITCH (Optional)

Periodic inspection of the shaft seal is recommended. Bearings are of the permanently

lubricated type.

PULLEY/SHAFT ASSEMBLIES

All crown curved pulley compression hubs are properly tightened to the manufacturers’

recommended torque at the factory. Shortly after initial start-up, the hub bolts should be

retightened to the following torques:

Shaft

Diameter

Torque

1

15/16”

180

in.

lbs.

2

3/16” 180

in.

lbs.

2

7/16” 180

in.

lbs.

2

15/16”

360

in.

lbs

Check every 2 to 6 months and retighten as needed.

5