Specifications maintenance – BVA Hydraulics J18992 User Manual

Page 4

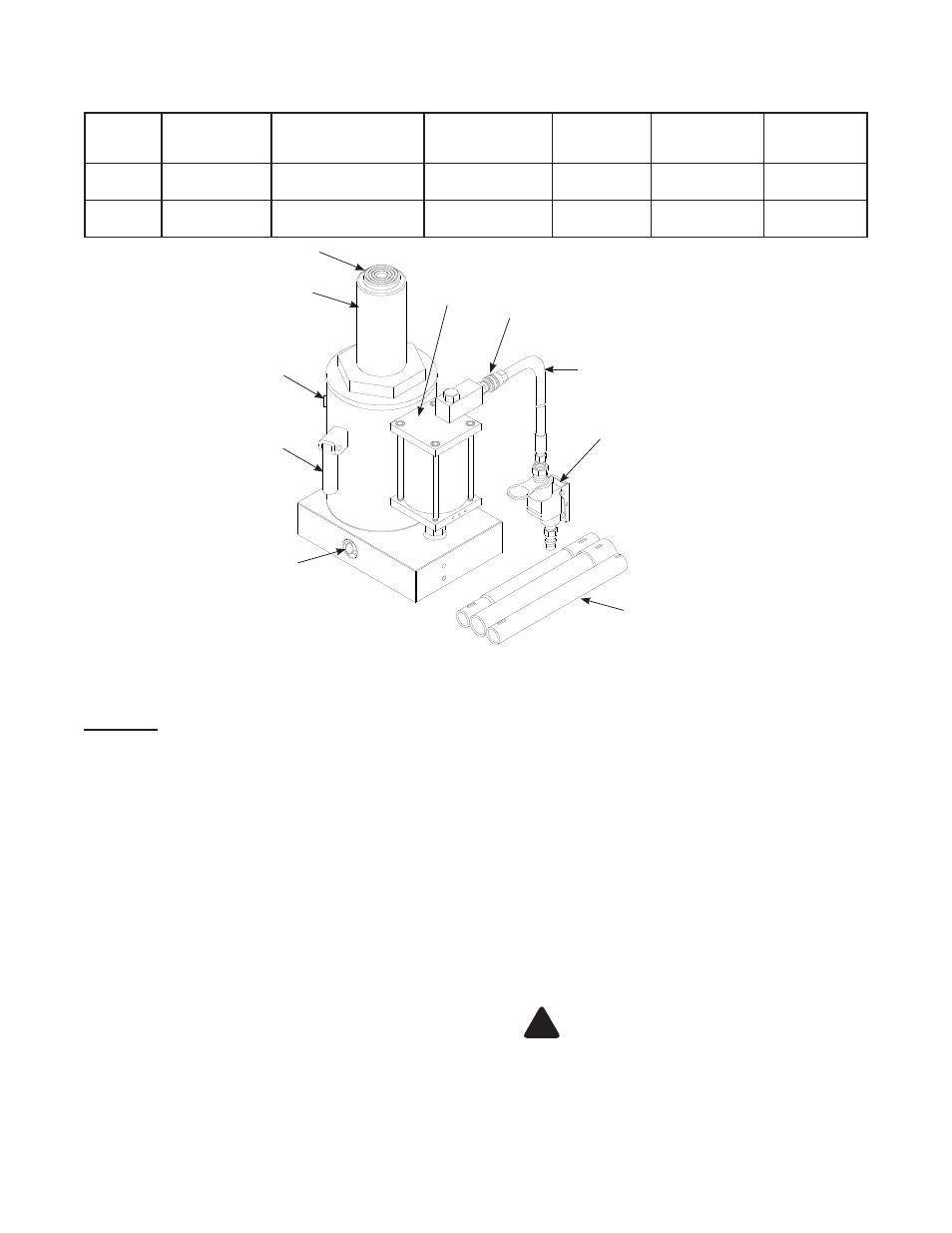

SPecIFIcatIOnS

MaIntenance

Important: Use only good grade hydraulic jack oil.

NEVER use brake fluid, turbine oil, transmission fluid,

motor oil or glycerin. Improper fluid can cause premature

failure of the jack and the potential for sudden and

immediate loss of load. We recommend Mobil DTE

13M or equivalent.

4

Figure 1 - J18502 & J18992 Nomenclature

Quick

Connector

Air Hose

Handle

Lift Control Valve

Release Valve

Oil Filler Screw

Carry Handle

Air Motor

Ram Plunger

Saddle

Model

Capacity

Base Size

(L x W)

Saddle Diameter Min. Height

Max. Height

Hydraulic Lift

J18502

50 Ton

10-7/8" x 7-3/8"

3-1/8"

12"

19"

7"

J18992

100 Ton

12-5/8" x 9-3/8"

4-1/2"

12"

18-1/8"

6-1/8"

adding oil

1. With saddle fully lowered and pump piston fully

depressed, set jack in its upright, level position.

Remove oil filler screw.

2.

Fill with oil until just below the rim of the oil filler hole.

Reinstall the oil filler screw.

changing oil

For best performance and longest life, replace the

complete fluid supply at least once per year.

1. With saddle fully lowered and pump piston fully

depressed, remove the oil filler screw.

2. Lay the jack on its side and drain the fluid into a

suitable container.

note: Dispose of hydraulic oil in accordance with local

regulations.

3.

Fill with oil until just below the rim of the oil filler hole.

Reinstall the oil filler screw.

Lubrication

1. A periodic coating of light lubricating oil to pivot points,

axles and hinges will help to prevent rust and assure

that pump assemblies move freely.

2. When used on a daily basis, air pump should be

internally lubricated before each use. Use

only good

quality air tool lubricant. If no inline oiler is used, pour

a teaspoon of air tool oil into the inlet of the air control

valve. Simply operate the jack with air pressure to fully

distribute the oil inside the air motor.

cleaning

Periodically check the pump piston and ram for signs of

rust or corrosion. Clean as needed and wipe with an oily

cloth.

note: Never use sandpaper or abrasive material

on these surfaces!

Storage

When not in use, store the jack with pump piston and

ram fully retracted and air supply disconnected.

Paint contains lead!

DO NOT sand or grind painted surface!

!