BVA Hydraulics PAR4003, PARD4001, PARD4003, PARM4003 User Manual

Page 5

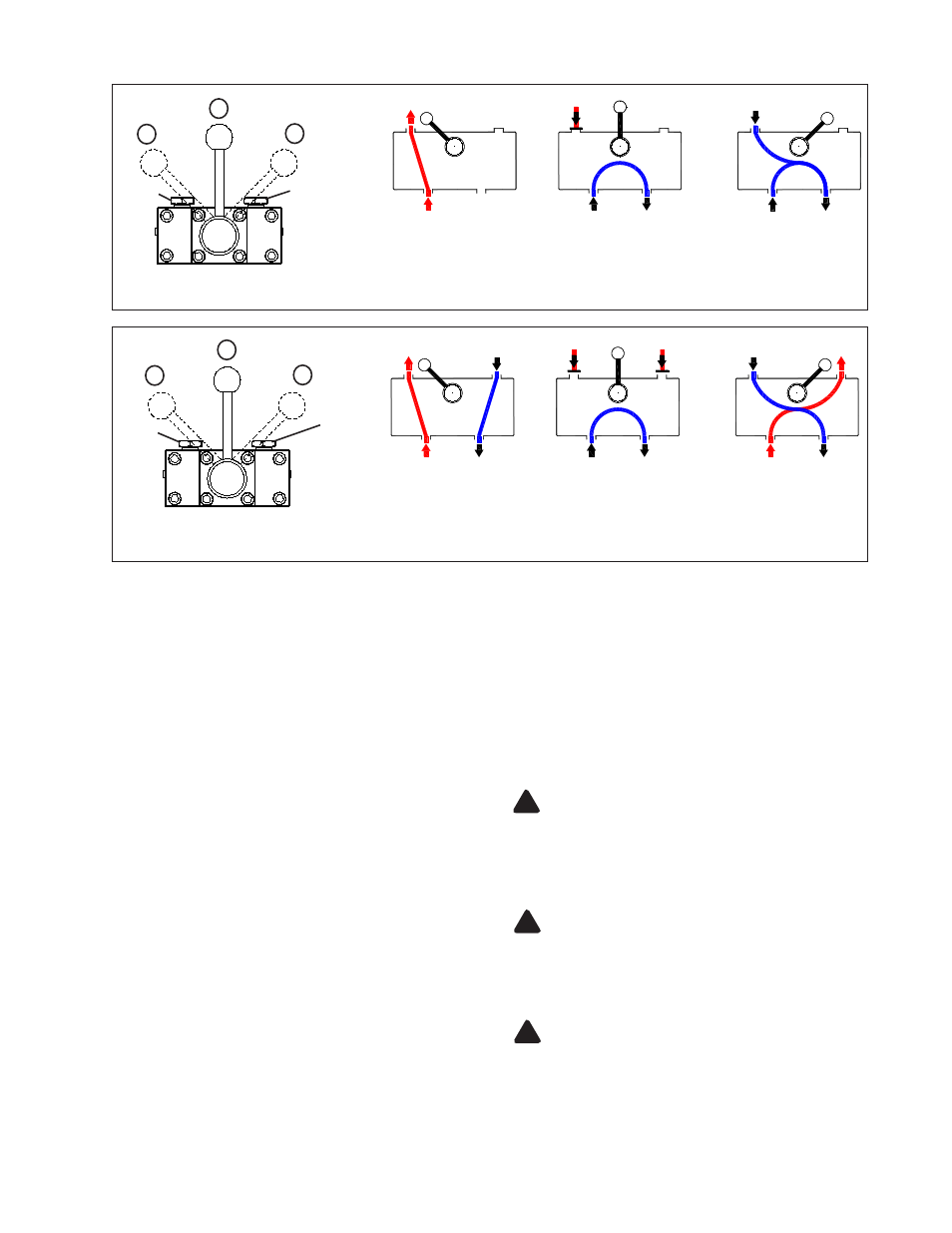

Position 1 (Advance):

Pressured oil flows to

port A.

Position 3 (Retract):

Port A returns flow to

tank.

Position 2 (Hold): Neu-

tral, ports A is closed.

Hold Position.

Port A

Port A

Port A

P T

P T

P T

Figure 5- Schematic flow path- PW3 Valve, 3-way, 3-position valve for Single-Acting Cylinder

Port A

Port B

1

2

3

BEFORE USE AND SET UP

1. Familiarize yourself with the specifications and

illustrations in this owners manual. Know your pump,

its limitations and how it operates before attempting to

use. Refer to specification chart on page 3 for details.

If in doubt, contact BVA Hydraulics Technical Service

(888) 332-6419.

4.

Air Connection: After making the necessary hydraulic

connections above, connect suitable air supply to air

input port. Ensure that your air source can dedicate 44~98

CFM @ 60~100 PSI for rated capacity performance. Refer

to the page 3 Product Specifications for specific pump

requirements.

2.

Hydraulic Connection: Clean all areas around the oil

port of pump and cylinder. Inspect all threads and fitting

for signs of wear or damage and replace as needed.

Clean all hose ends, couplers and union ends. Remove

the manifold plug, then connect oil output port to suitable

fittings and application/cylinder.

IMPORTANT: Always secure threaded port connections

with high grade, non-hardening pipe thread sealant. Teflon

tape can be used if only one layer of tape is used and it

is applied carefully, two threads back, to prevent the tape

from being introduced into hydraulic system, which could

cause jamming of precision-fit parts.

!

Once connected to the intended air source, pump

will be energized and oil will flow from the pump to the

tank.

Ensure pump lever is in the 'neutral' position

on pumps equipped with PW3, PW4 valves.

!

Once connected to the intended air source, pump

PAR4003, PARM4003:

will be energized and oil will flow from the pump to the

application.

ENSURE operator is aware that applica-

tion will be pressurized

immediately upon connecting

air source.

PARD4001, PARD4003:

Port A

Port B

Position 1: Pressured

oil flows to port A, port B

returns flow to tank.

Position 3: Pressurized

oil flows to port B, port A

returns flow to tank.

Position 2: Neutral,

ports A & B are closed.

Hold Position

Port A Port B

Port A Port B

Port A Port B

P T

P T

P T

1

2

3

BVA Pump Mounted Valves are

tandem center valves.

Tandem centered valves allow oil to flow from the pump

to tank when in the

NEUTRAL position.

Tandem centered valves

must be in "neutral" lever

position before starting pump. To pressurize the pump

manifold or the application (cylinder, spreader, etc.),

simply position the lever left or right of center.

5

Figure 6- Schematic flow path- PW4 Valve, 4-way, 3-position valve for Double-Acting Cylinder

Never operate a pump which is disconnected from

application. If operated in this condition, the hose

and connections will become pressurized. This increases

burst hazard.

!