BVA Hydraulics P240L User Manual

Page 4

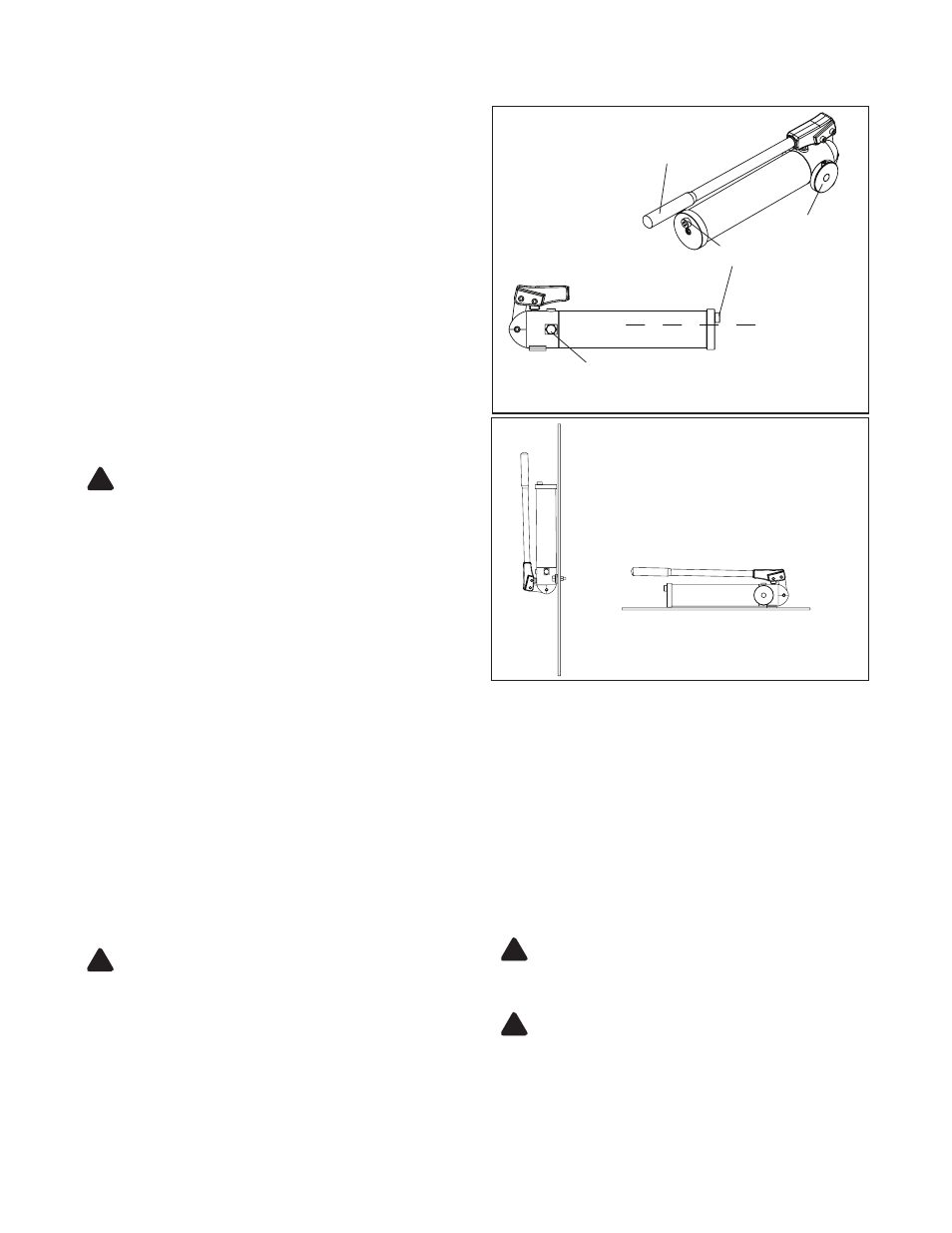

1. Read, understand, and follow the SET UP section on

page 4.

2. Pump may be used in any of the two positions shown in

Figure 6.

BEFOrE USE

1. Before using this product, read the instruction manual

completely and familiarize yourself thoroughly with the

product, its components and recognize the hazards

associated with its use.

2. Verify that the product and the application are compatible.

Inspect before each use. Do not use if bent, broken, leaking

or damaged components are noted.

3. Replace worn or damaged parts and assemblies with

BVA Hydraulics Authorized Replacement Parts only (See

Replacement Parts Section). Lubricate as instructed in

Maintenance Section.

4. Ensure method of confirming load is accurate and working

properly. Have gauge or load cell accuracy verified by

qualified personnel on a yearly basis.

5. Pump should be stored where protected from the

elements, abrasive dust, and temperature

extremes. Pump should be stored horizontally.

note: Pump may be used and stored vertically, but only

as oriented in Fig 4.

SEt UP

(refer to Figures 1, 3)

This pump’s maximum working pressure is

7,200 psi. Ensure that all hydraulic equipment

such as cylinders, hoses, couplers and etc. used with this

pump are rated at 7,200 psi or more.

1. Set the pump on a hard flat surface, i.e. a work bench.

Remove the oil filler screw found on rear end cap to check

fluid level. Correct fluid level is even with the oil filler screw

hole.

2. Carefully remove the threaded plug on oil outlet port. *Install

a pressure gauge in-line between the pump and application.

Port connection is 1/4”NPTF. It is recommended to use

a BVA CA3814 fitting, CF3814 gauge adapter, GW2514

gauge, and a CB1438 fitting to install.

These items must be purchased separately.

note:

Always secure threaded connections with non-hardening

pipe thread compound. Take care not to introduce compound

into port orifices. Tighten securely to prevent accidental

removal of components while in use.

3. Tighten securely to prevent accidental removal of

components while in use.

4. Check for leaks in system and repair by qualified personnel

as needed. Depressurize the hydraulic system before

servicing.

4

Figure 3

- Set Up Illustration

oil filler screw

release valve

operating handle

correct oil level

oil output port 1/4”-18NPTF

Figure 4

- Use / Storage Positions

* A load cell and digital display may be used in addition to

or

instead of a pressure gauge.

ALWAYS monitor pressure, load or position using

suitable equipment. Pressure may be monitored

by means of an optional manifold and gauge (contact BVA

Hydraulics). Load may be monitored by means of a load cell

and digital indicator. Correct application position can only be

determined by the operator of the equipment.

!

to Use:

A. Close release valve by turning it clockwise. Finger tighten

ONLY. Using tools on release valve can destroy the

pump.

B. Pump handle until desired pressure, load or position is

reached.

C. Secure load with appropriate means.

D. To retract application, turn the release valve knob slowly

counterclockwise (never more than 2 full turns).

NEVER operate pump with release valve closed and

disconnected from application.

OPEratIOn

!

NEVER rely on hydraulic pressure alone to secure

a load!

NEVER allow personnel to work or pass

under a load until the load is secured by cribbing, blocking,

or other mechanical means.

!

!