Reliability test, Bestar electronics industry co.,ltd – BeStar FT-39T-2.5B1 User Manual

Page 6

T

h

is

p

ri

n

t

a

n

d

i

n

fo

rm

a

tio

n

t

he

re

i

n

a

re

p

ro

p

ri

e

ta

ry

t

o

B

e

s

ta

r

E

le

c

tr

o

n

ics

I

ndu

s

tr

y

C

o

.,

L

td.

a

nd

s

h

a

ll

no

t

b

e

u

s

ed

i

n

w

h

o

le

o

r

in

pa

rt

w

ith

ou

t

it

s

w

ri

tt

en

c

on

tent

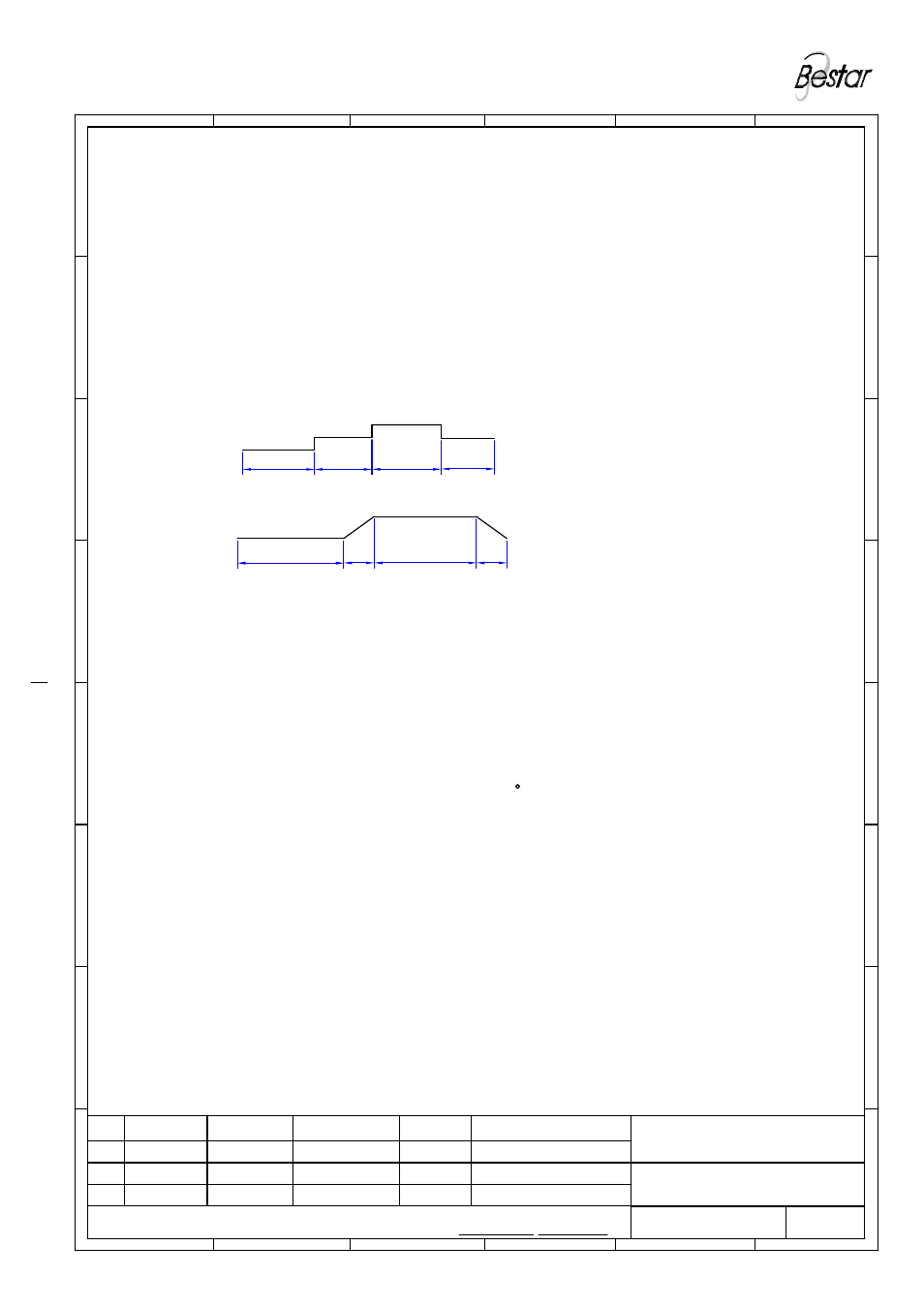

6.5 Vibration Test

Vibration Frequency 10~55Hz

Amplitude 1.53mm

Direction 3(x.y&z)

Duration 2hrs each direction (total 6 hrs)

6.6 Drop test

Height 100cm

(to 10mm thickness woodenboard)

Direction 3(x.y&z)

6.7 Solderability Test

Soldering Temperature 230 C

Duration 3 sec

6.8 Accelerated Life Test (ALT)

Thermal Cycling :

Thermal Cycling consists of temperature ramping components for 30 minutes in the

Testing oven from -20

°C to 70°C. The components are then exposed for 1 hour at

The extremes and the cycle is repeated for a total of 15 cycles..

Thermal Soak:

Thermal soak consists of exposing a powered unit to 70

°C and 85% relative humidity

for 45 days.

Notice: All specifications must be satisfied in this condition.

J 09/08/31 汤浩君

I 09/05/11 汤浩君

H 09/01/17 汤浩君

BESTAR ELECTRONICS INDUSTRY CO.,LTD

Rev.

Date

6

A

B

C

D

李红元

Drawn

Note

Approved by:

Page:06 of 08

5

4

DRG NO: BS/TEY01.117J

3

2

1

Piezo Ceramic Element

Date:

Drawn by:

Checked by:

09/08/31

汤浩君

赵

峥

FT-39T-2.5B1

A

B

C

D

FT-39T-2.5B1

6.1 Life test at high temperature

Temperature +85

°C

Duration 240hrs

6.2 Life test at low temperature

Temperature -40

°C

Duration 240hrs

6.3 Temperature cycle test

Cycles 5

6.4 Humidity cycle test

Cycles 5

All these tests above should be measured after leaving normal temperature for 2hrs.

6. Reliability test

E

F

G

H

6

+85

℃

1h

12h

1h

10h

+20

℃

15min

25℃90-95% RH

-40

℃

30min

65℃ 90-95% RH

30min

+20

℃

15min

E

F

G

H

博 士 達

5

4

3

2

1