Model qpt number description – Anemostat EST User Manual

Page 5

5

1220 Watson Center Road • Carson, CA 90745

Tel: (310) 835-7500 • Fax: (310) 835-0448

www.anemostat.com • [email protected]

Model QPT Number Description

Digit 1, 2, 3 - Model

QPT

Parallel flow fan powered terminal

Digit 4 - Heat options

S

Standard

W

Hot water coil

E

Electric heat

Digit 5, 6, 7, 8, 9 - Cabinet size, Fan HP and Primary inlet size

1 17 06 1/6 hp 6” inlet

1 17 07

1/6 hp 7” inlet

1 17 08 1/6 hp 8” inlet

1 17 09 1/6 hp 9” inlet

1 25 06 1/4 hp 6” inlet

1 25 07

1/4 hp 7” inlet

1 25 08 1/4 hp 8” inlet

1 25 09 1/4 hp 9” inlet

2 17 09

1/6 hp 9” inlet

2 17 10

1/6 hp 10” inlet

2 17 12

1/6 hp 12” inlet

2 25 09

1/4 hp 9” inlet

2 25 10

1/4 hp 10” inlet

2 25 12

1/4 hp 12” inlet

Digit 10 - Casing Construction

B

single wall 20ga. Steel (standard)

E

double wall 22ga. Steel

(1/2” glass fiber insulation)

Digit 11 - Insulation and Treatment

0 None

1

1/2” matte-faced glass fiber insulation

(double wall only)

2

1” matte-faced glass fiber insulation (standard)

3

1/2” foil-faced glass fiber

(tape over all insulation edges)

4

1” foil-faced glass fiber

(tape covers insulation edges)

5

3/8” closed cell insulation (fiber free)

Digit 12 - Control Type

0 None

P

Pneumatic

A

Electronic Analog

F

Supplied by others – factory mounted

Digits 13, 14, 15, 16 - Control Package

0000 None (field supplied by others)

XXXX Refer to available control packages

Digit 17 - Control location

(determined by facing inlet)

L

left hand

Digits 18, 19, 20, 21 - Primary air minimum airflow

0000

None specified

XXXX Specify minimum airflow setting in CFM

Digits 22, 23, 24, 25 - Primary air maximum airflow

0000

None specified

XXXX Specify maximum primary airflow setting in CFM.

Digit 26 - Heating coil and connection location (determine

by facing inlet)

0 None

A

One-row hot water coil - right hand

B

One-row hot water coil - left hand

C

Two-row hot water coil - right hand

D

Two-row hot water coil - left hand

K

Electric heat - connections same side as digit 17

Digit 27 - Fan Motor Voltage

1

115V/ 1 Ph./ 60 Hz.

2

277V/ 1 Ph./ 60 Hz.

Note: Standard motor is 3 speed multi-tap PSC

Digit 28 - Electric Coil Voltage and Steps

0 None

A

208V/ 1 Ph/ 60Hz. 1 step

B

208V/ 1 Ph/ 60Hz. 2 step

C

208V/ 1 Ph/ 60Hz. 3 step

D

240V/ 1 Ph/ 60Hz. 1 step

E

240V/ 1 Ph/ 60Hz. 2 step

F

240V/ 1 Ph/ 60Hz. 3 step

G

277V/ 1 Ph/ 60Hz. 1 step

H

277V/ 1 Ph/ 60Hz. 2 step

J

277V/ 1 Ph/ 60Hz. 3 step

K

208V/ 3 Ph/ 60Hz. 1 step

L

208V/ 3 Ph/ 60Hz. 2 step

M

208V/ 3 Ph/ 60Hz 3 step

N

480V/ 3 Ph/ 60Hz. 1 step

P

480V/ 3 Ph/ 60Hz. 2 step

R

480V/ 3 Ph/ 60Hz. 3 step

Note: 3 steps not available with night setback control packages

Digits 29, 30. 31 - Electric coil KW

000 None

XXX Refer to notes on pages 369 and 370 for

allowable range

Digit 32 and over - Options and Accessories

C1

Unit mounting brackets

C2

Manual damper locking quadrant (shipped loose)

C4

Hinged front panel control enclosure

C5

Discharge collar (“S” units only)

D3

Line voltage SPST disconnect switch (120V, 277V)

D5

Line voltage power-fusing

(fuse and block for 120V, 277V)

(terminal selector block standard)

D7

Three speed motor switch

(terminal selector block standard)

D8

Fan Relay, 24 VAC Coil, SPST / N.O.

(for DDC controls by others)

D9

24 VAC Electric Actuator

DA

24 VAC Transformer, 40 VA

E1

Non-fused interlocking disconnect switch

for Electric heat

E2

Electric heat Mercury de-energizing contactors

E3

Electric heat power fusing

(fuses and fuse blocks)

E4

Electric heat manual reset secondary thermal cutout

E6

AirFlow proving switch

F1

One inch throwaway filters

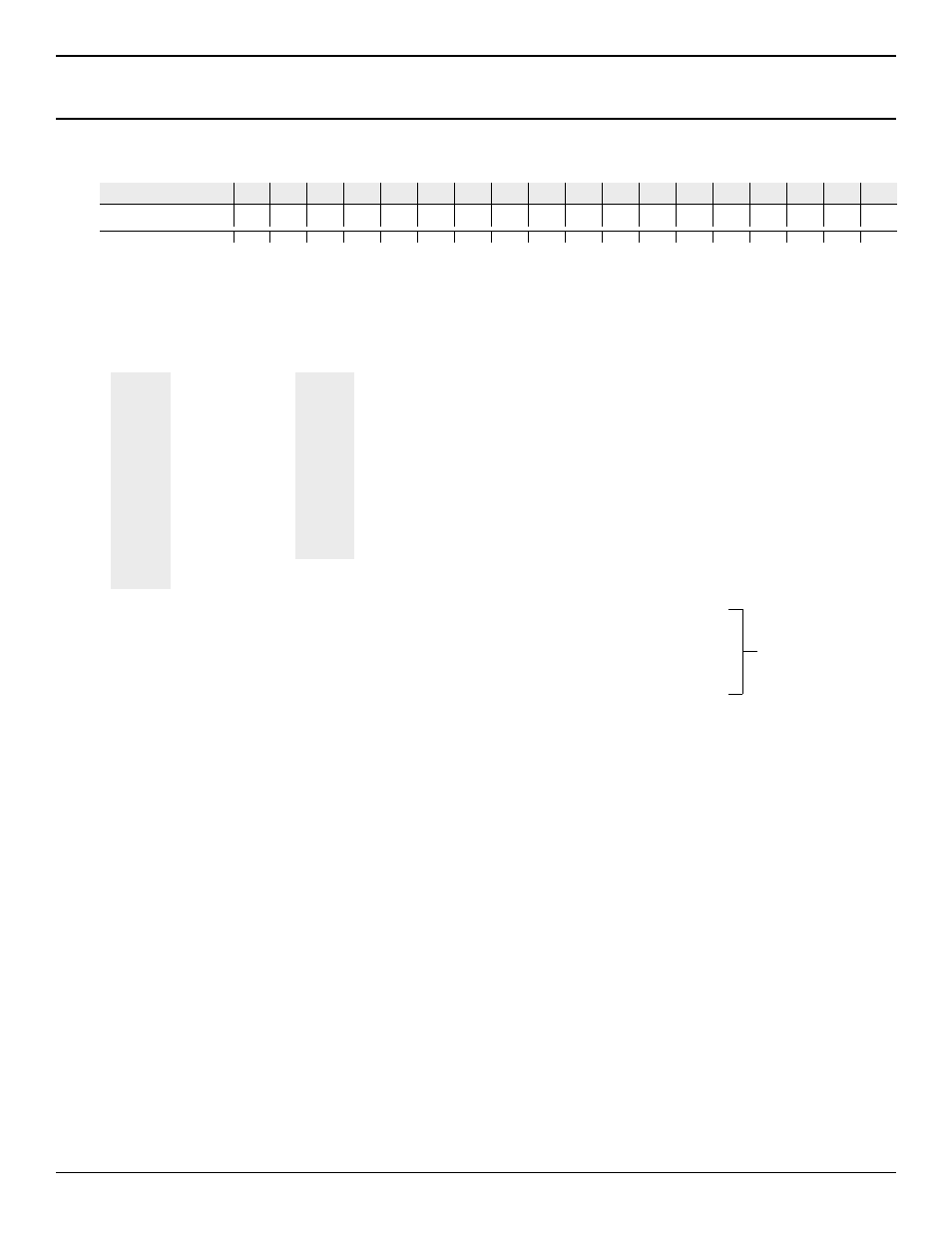

Standard Digits

1-3

4

5

6,7

8,9

10

11

12

13-16

17

18-21

22-25

26

27

28

29-31

32-33

34-35

36-+

Description

Model

Heat

Cabinet

HP

Inlet

Casing

Insul

Cntrl

Cntrl

LH

Min

Max

Heat

Fan

Coil

Elec

Opt

Opt

Opt

Num

Size

Size

Type

Pkg

CFM

CFM

Config

VAC

VAC

KW

Example

QPT

W

1

17

06

B

1

A

5001

L

0100

1450

E

1

G

12.0

C1

C4

F1

2 50 09

1/2 hp 9” inlet

2 50 10

1/2 hp 10” inlet

2 50 12

1/2 hp 12” inlet

3 50 12

1/2 hp 12” inlet

3 50 14

1/2 hp 14” inlet

3 50 16

1/2 hp 16” inlet

3 75 12

3/4 hp 12” inlet

3 75 14

3/4 hp 14” inlet

3 75 16

3/4 hp 16” inlet

3 10 12

1 hp 12” inlet

3 10 14

1 hp 14” inlet

3 10 16

1 hp 16” inlet

Must be 4 wire

WYE configuration